Product Advantages

✔ Dual-diaphragm design extends product service life.

✔ Pulse-optimized design ensures 500,000 switching cycles lifespan.

✔ Tower-spring configuration optimizes membrane return stability

✔ Clamp-ring coil design enables easy maintenance and replacement.

✔ Optional high-temperature or low-temperature resistant diaphragms available (-40°C to 200°C).

The SENYA DMF-Y Series pilot-operated pulse valves are engineered specifically for industrial dust collection applications, offering reliable performance within a 3-5 bar operating pressure range. These valves serve as critical components in pulse-jet cleaning systems for baghouse filters across multiple industries including flour milling, furniture manufacturing, cement production, and general industrial dust removal operations. The advanced pilot-operated design ensures rapid response times and consistent diaphragm movement, delivering powerful cleaning pulses to maintain optimal filtration efficiency.

Featuring a user-friendly snap-ring coil mounting system, the DMF-Y Series allows for quick, tool-free coil replacement – a significant advantage in maintenance-heavy industrial environments where downtime must be minimized. The valves are constructed with industrial-grade materials that resist corrosion and wear from prolonged exposure to various dust types, from fine organic particles in food processing to abrasive mineral dust in cement plants.

For applications with extreme temperature requirements, the series offers optional high-performance sealing materials including high-temperature resistant elastomers and low-temperature compatible compounds, making these valves suitable for environments ranging from hot cement kiln exhaust systems to climate-controlled food production facilities. The compact yet robust design ensures reliable operation in space-constrained installations while withstanding the vibrations and mechanical stresses common in industrial settings.

Standard features include corrosion-resistant aluminum valve bodies, durable diaphragms rated for millions of cycles, and industry-standard NPT threaded connections for easy integration into existing systems. Optional configurations include different port sizes, special coatings for corrosive environments, and explosion-proof versions for hazardous locations. With its combination of reliable performance, easy maintenance, and application flexibility, the DMF-Y Series provides dust collection system operators with a cost-effective, long-lasting solution that helps maintain clean air standards while optimizing operational efficiency. The valves are designed to meet international standards for industrial air pollution control equipment and are backed by comprehensive technical support.

|

Category |

2/2 ways |

|

Way of action |

pilot operated |

|

Series |

DMF-Y |

|

Body Material |

Cast aluminium |

|

Way to control |

solenoid valve |

|

Pressure resistance |

0.3- 0.8 Mpa |

|

Sealing material |

NBR |

|

Temperature |

-5 ~ 55 ℃ (-40 ~80℃) |

|

port range |

3/4″ ~ 3″ |

|

Normally open normally closed |

N.C. |

|

Wiring |

DIN connector |

|

Protection level |

IP65 |

|

way to install |

bracket required |

|

Recommended installation method |

horizontally |

|

thread option |

BSP, NPT thread |

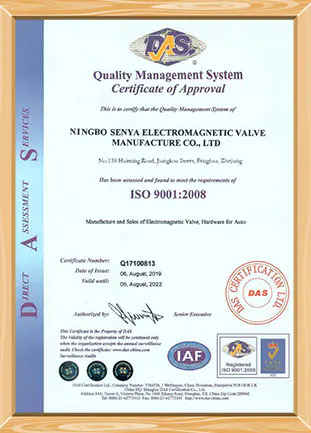

ISO 9001:2008

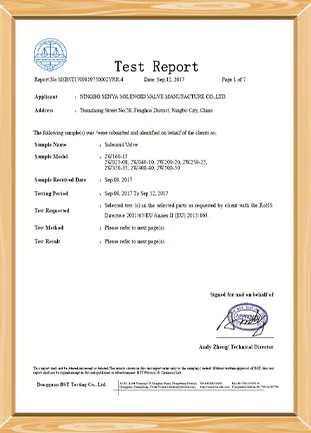

Test Report

CE

SGS

QMS

CTB231229044CX-ZS CE ROHS certification