The brass solenoid valve market demonstrates significant expansion. It was valued at USD 1.21 billion in 2021 and reached USD 2.5 billion in 2024. Analysts project a Compound Annual Growth Rate (CAGR) of 3.80% from 2022 to 2029, with the market expected to reach USD 1.63 billion by 2029. This robust growth highlights the need for top-tier manufacturers. Many firms produce high-quality brass solenoid valves. For instance, Ningbo SENYA Pneumatic Technology, a prominent Ningbo brass solenoid valve supplier, operates as a leading brass solenoid valve factory. They are among the best brass solenoid valve manufacturers in China. A dependable solenoid valve supplier offers durable and innovative products.

Key Takeaways

- Top companies like ASCO and Parker Hannifin make high-quality brass solenoid valves. These valves work well in many different industries.

- Good brass solenoid valves are strong and last a long time. They also use new technology to save energy and work better.

- When you pick a valve, make sure it fits your needs. Look for good customer help and a strong warranty.

- Certifications like CE and UL show that valves are safe and meet important rules. This helps you trust the product.

Leading Manufacturers of Brass Solenoid Valves

ASCO (Emerson)

ASCO, now part of Emerson, stands as a global leader in fluid control solutions. The company has a long history of innovation. It consistently delivers high-performance products. ASCO’s brass solenoid valves are known for their reliability and durability. They serve a wide range of industries. These industries include industrial automation, medical, and commercial applications. ASCO offers an extensive portfolio. This portfolio includes 2-way, 3-way, and 4-way valves. They come in various sizes and configurations. This variety ensures customers find the right solution for their specific needs. ASCO’s commitment to quality and engineering excellence makes them a top choice for critical applications.

Parker Hannifin

Parker Hannifin is a diversified manufacturer of motion and control technologies. The company provides a broad array of solutions. Their brass solenoid valve offerings are comprehensive. Parker Hannifin designs these valves for demanding environments. They ensure optimal performance and longevity. The company’s global presence allows them to support customers worldwide. Parker Hannifin’s product lines include various types of brass solenoid valves. For example, they offer Parker 2-Way Normally Closed, 1/2″ General Purpose Solenoid Valves. They also provide Parker 2-Way Normally Open, 1″ NPT General Purpose Solenoid Valves. These products demonstrate Parker’s commitment to diverse application requirements. Their engineering expertise ensures high-quality and reliable fluid control.

Burkert Fluid Control Systems

Burkert Fluid Control Systems specializes in measuring and controlling fluid systems. The company is renowned for its precision engineering. Burkert’s brass solenoid valves are a testament to this expertise. They design these valves for accuracy and efficiency. Burkert serves industries such as water treatment, pharmaceuticals, and food and beverage. Their valves often feature compact designs and advanced control options. This allows for seamless integration into complex systems. Burkert focuses on innovative solutions. They provide reliable and precise fluid control for various applications.

Danfoss

Danfoss is a global leader in climate and energy-efficient solutions. The company brings extensive expertise to its brass solenoid valve production. Danfoss designs these valves for energy efficiency and robust performance across various applications. Their commitment to sustainability drives their product development. Danfoss brass solenoid valves find use in diverse systems. They handle media such as:

- Compressed air

- Drinking water (up to 90°C)

- Hot water (up to 140°C)

- Technical water

- Steam

This versatility makes them suitable for many industrial and commercial settings. Danfoss emphasizes reliability and long operational life in its valve designs. They offer a range of direct-acting and servo-operated valves. This ensures precise control and efficient operation in demanding environments.

SMC Corporation

SMC Corporation is a world leader in pneumatic technology. The company offers a vast array of automation components, including high-quality brass solenoid valves. SMC focuses on innovation and compact designs. This allows for seamless integration into complex machinery and systems. Their brass solenoid valves are known for their precision and rapid response times. SMC serves industries such as automotive, electronics, and packaging. They provide solutions that enhance productivity and efficiency. The company’s extensive research and development efforts ensure cutting-edge products. SMC’s global manufacturing and distribution network supports customers worldwide. They deliver reliable and technologically advanced fluid control solutions.

Norgren (IMI Precision Engineering)

Norgren, a brand of IMI Precision Engineering, specializes in high-performance fluid control and motion products. Norgren’s brass solenoid valves are engineered for demanding industrial applications. They offer robust construction and reliable operation. The company provides customized solutions to meet specific customer requirements. Norgren’s expertise spans various sectors, including commercial vehicles, energy, and process industries. Their valves ensure precise control of fluids and gases. Norgren focuses on durability and performance under harsh conditions. They leverage advanced engineering to develop innovative valve technologies. This commitment to quality and tailored solutions establishes Norgren as a key player in the brass solenoid valve market.

ODE S.r.l.

ODE S.r.l. stands as a prominent Italian manufacturer. They specialize in solenoid valves and pumps. The company has a strong reputation for quality and reliability. ODE designs and produces a wide range of brass solenoid valves. These valves cater to various industrial and commercial applications. Their products often feature robust construction. They also offer precise fluid control. ODE emphasizes Italian craftsmanship in its manufacturing processes. This commitment ensures high-performance and durable valves.

ODE’s brass solenoid valves find use in many sectors. These include:

- Coffee machines ☕

- Industrial automation

- Water treatment systems

- Medical equipment

The company offers different valve types. These include direct-acting, pilot-operated, and proportional valves. This variety allows customers to select the best solution for their specific needs. ODE also focuses on innovation. They continuously develop new technologies. This ensures their valves meet evolving market demands. Their global distribution network supports customers worldwide. ODE provides excellent technical assistance and after-sales service.

CEME S.p.A.

CEME S.p.A. is another leading Italian company. They specialize in the production of solenoid valves and pumps. CEME has established itself as a key supplier for Original Equipment Manufacturers (OEMs). The company offers a comprehensive range of brass solenoid valves. They design these valves for integration into various systems and appliances. CEME’s strength lies in its ability to customize products. They meet specific customer requirements. This flexibility makes them a preferred partner for many industries.

CEME’s brass solenoid valves are known for their:

- Compact design

- High performance

- Long operational life

They serve diverse applications. These include:

- Home appliances 🏠

- Vending machines

- Automotive systems

- Industrial machinery

The company invests heavily in research and development. This ensures their products remain at the forefront of technology. CEME maintains strict quality control standards. They guarantee reliable and consistent valve performance. Their efficient production capabilities allow them to handle large volumes. They also deliver customized solutions promptly. CEME’s dedication to quality and customer satisfaction makes them a significant player in the brass solenoid valve market.

NIBCO

NIBCO is a well-established American manufacturer. They produce a wide array of flow control products. The company has a long history, dating back to 1904. NIBCO offers high-quality brass valves. These include various types of solenoid valves. They design their brass products for durability and reliable performance. NIBCO serves residential, commercial, and industrial markets. Their extensive product line meets diverse plumbing and HVAC needs.

NIBCO’s brass solenoid valves provide robust solutions for fluid control. They often feature:

- Corrosion resistance

- High-pressure ratings

- Ease of installation

The company emphasizes stringent manufacturing processes. They ensure their valves meet industry standards. NIBCO’s commitment to quality extends to its customer support. They offer comprehensive technical resources. They also provide excellent service. Their strong distribution network ensures product availability across North America and beyond. NIBCO’s century-long experience in valve manufacturing positions them as a trusted provider of brass solenoid valves. They deliver dependable products for critical applications.

United Brass

United Brass, Inc. has a long-standing reputation for manufacturing high-quality brass valves. The company specializes in producing durable and reliable brass products. They offer a range of brass solenoid valves. These valves meet the demands of various industrial and commercial applications. United Brass focuses on robust construction and precision engineering. This ensures their valves perform consistently in challenging environments. Their product line includes valves suitable for water, air, and light oil. They provide different port sizes and voltage options. This versatility allows customers to find appropriate solutions for specific system requirements.

United Brass emphasizes quality control throughout its manufacturing process. They use premium brass materials. This enhances the longevity and corrosion resistance of their solenoid valves. The company also offers customization options. This allows them to tailor valves to unique operational needs. Their commitment to customer satisfaction extends to providing reliable technical support. United Brass serves industries such as plumbing, HVAC, and general industrial fluid control. Their extensive experience in brass manufacturing positions them as a trusted provider of dependable solenoid valve solutions.

VERSA Products

VERSA Products is a recognized leader in manufacturing high-performance industrial valves. The company specializes in robust and reliable solenoid valves. They design these valves for demanding applications. VERSA’s brass solenoid valves are known for their exceptional durability and long service life. They engineer these products to withstand harsh operating conditions. This includes extreme temperatures and corrosive media. VERSA offers a comprehensive range of brass solenoid valves. These include 2-way, 3-way, and 4-way configurations. They also provide various actuation methods.

VERSA Products prioritizes precision and reliability in its valve designs. Their valves often feature modular construction. This simplifies maintenance and increases operational flexibility. The company serves critical industries. These include oil and gas, chemical processing, and power generation. VERSA’s commitment to engineering excellence ensures their brass solenoid valves deliver consistent performance. They meet stringent industry standards. Their global presence and extensive distribution network support customers worldwide. VERSA provides high-quality fluid control solutions for complex industrial systems.

WIC Valve

WIC Valve specializes in manufacturing electric solenoid valves. The company focuses on providing reliable and cost-effective solutions. They offer a diverse range of brass solenoid valves. These valves cater to various applications. WIC Valve designs its products for precision control and efficient operation. Their brass solenoid valves are suitable for controlling air, water, oil, and gas. They provide different valve types. These include normally closed, normally open, and direct-acting models.

WIC Valve emphasizes compact designs and ease of integration. This makes their valves ideal for OEM applications and automated systems. The company maintains strict quality standards in its manufacturing processes. This ensures consistent performance and durability. WIC Valve offers a variety of port sizes and voltage options. This allows for broad applicability across different industries. Their commitment to innovation drives the development of new valve technologies. WIC Valve provides dependable and versatile brass solenoid valve solutions. They support a wide array of fluid control needs.

Ningbo SENYA Pneumatic Technology Co., Ltd.

Ningbo SENYA Pneumatic Technology Co., Ltd. stands as a prominent integrated organization. They manufacture and export a wide range of pneumatic components. The company operates as a leading Chinese pneumatic component manufacturer and factory. They focus on producing high-quality valves, cylinders, and other pneumatic-related products. Ningbo SENYA has established a strong brand reputation. They also possess rich industrial application experience. This expertise positions them as a top brass solenoid valve manufacturer in China.

The company excels in the production of brass solenoid valves. They offer robust and reliable solutions for various industrial needs. Ningbo SENYA’s manufacturing processes integrate advanced technology. This ensures precision and durability in every product. Their commitment to quality makes them a trusted supplier. Customers rely on their valves for consistent performance in demanding environments.

Ningbo SENYA’s product portfolio includes diverse brass solenoid valve types. These valves cater to a broad spectrum of applications. They design their products for optimal fluid control and efficiency. The company’s integrated approach covers design, production, and export. This allows them to maintain strict quality control throughout the entire process. Their focus on customer satisfaction drives continuous innovation. They consistently meet evolving market demands.

The company’s extensive experience in the pneumatic industry provides a significant advantage. They understand the critical requirements of various sectors. This knowledge translates into superior product design and functionality. Ningbo SENYA serves both domestic and international markets. They provide reliable and high-performance brass solenoid valves to a global clientele. Their dedication to excellence solidifies their position as a key player in the brass solenoid valve market.

Defining Excellence in Brass Solenoid Valve Manufacturing

Excellence in brass solenoid valve manufacturing involves a combination of stringent quality control, continuous innovation, and proven reliability. Top manufacturers consistently meet high standards. They ensure their products perform optimally in diverse applications.

Quality and Durability Standards for Brass Solenoid Valves

Manufacturers establish rigorous quality and durability standards for brass solenoid valves. Brass offers excellent media compatibility for water and non-acidic fluids, resisting corrosion in moist environments. Its machinability allows for precise shapes and smooth internal surfaces, reducing flow resistance and ensuring reliable performance. Brass also provides good thermal and electrical conductivity, crucial for temperature control and electrical operation. This material is cost-effective and durable, leading to less frequent replacement within allowable limits. However, brass has limitations. It exhibits limited chemical resistance, degrading in acidic environments. It also risks dezincification, where zinc leaches out, weakening the material, especially with acidic or alkaline water. Furthermore, brass has pressure and temperature limitations, with a lower melting point and pressure endurance compared to other materials. This can lead to premature failure in high-temperature or high-pressure applications.

Innovation and Technology Integration in Brass Solenoid Valves

Innovation drives progress in brass solenoid valve technology. Leading firms integrate advanced materials and smart features into their designs. They develop new coil technologies for reduced power consumption. Miniaturization allows for more compact and efficient valves. Digital control interfaces enhance precision and remote operation. Manufacturers also explore new sealing materials. These materials improve chemical compatibility and extend valve lifespan. These technological advancements ensure valves meet the evolving demands of modern industrial systems.

Reliability and Performance Metrics of Brass Solenoid Valves

Reliability is paramount for brass solenoid valve operation. Manufacturers evaluate performance using several key metrics. Flow rate directly influences system efficiency; optimizing it can increase output. A lower pressure drop leads to higher efficiency and better performance. Faster response times enhance operation in time-sensitive applications. Other metrics include cycle life, leakage rates, and resistance to environmental factors. Consistent performance across these metrics defines a superior brass solenoid valve.

Customer Support and Service for Brass Solenoid Valves

Exceptional customer support and service significantly enhance the value of brass solenoid valves. Leading manufacturers offer comprehensive technical assistance. They provide expert guidance on product selection, installation, and troubleshooting. This support ensures customers choose the correct valve for their specific application. It also helps them optimize system performance. Manufacturers often maintain readily available spare parts. This minimizes downtime and extends the operational life of their valves. Responsive service teams address inquiries promptly. They resolve issues efficiently. This commitment to post-sales support builds strong customer relationships. It also reinforces a brand’s reputation for reliability.

Certifications and Compliance for Brass Solenoid Valves

Certifications and compliance are crucial for brass solenoid valves. They ensure product safety, quality, and environmental responsibility. Manufacturers adhere to various international and regional standards. This guarantees their valves meet stringent regulatory requirements.

| Certification | Focus Area | Applicable Regions |

|---|---|---|

| CE | Health, safety, and environment | Europe |

| RoHS 3 | Restriction of hazardous substances | Europe and globally for exports |

| UL | Safety (electrical & fire) | U.S. |

| CSA | Safety (electrical & mechanical) | Canada |

| NSF | Food & water safety | U.S. & International |

The CE marking, or “European Conformity,” is a mandatory certification for products sold within the European Economic Area. It indicates compliance with EU health, safety, and environmental protection standards. Valves often fall into these regulated product sectors. RoHS 3 certification signifies adherence to the Restriction of Hazardous Substances Directive. This directive limits the use of specific hazardous materials in electrical and electronic items. It prevents health and environmental issues. For a valve to be RoHS certified, it must contain specific maximum levels of substances like lead and mercury.

The UL mark from Underwriter Laboratories indicates a product has undergone safety testing. It meets stringent safety standards, especially for electrical devices like solenoid valves. The US Occupational Safety and Health Administration (OSHA) recognizes UL certification. In North American markets, brass solenoid valves must also comply with certifications such as NSF/ANSI and CSA standards. This is especially true when used in water and gas applications. This comprehensive regulatory framework ensures safety, environmental protection, and product quality.

In-Depth Profiles of Top Brass Solenoid Valve Producers

ASCO: Industry Leadership and Broad Product Range

ASCO, a division of Emerson, consistently demonstrates industry leadership in fluid control. They offer an extensive and diverse product range. ASCO’s brass solenoid valves are renowned for their robust construction and reliable operation across various applications. The company designs these valves for longevity and consistent performance in demanding industrial environments. Their portfolio includes a wide array of configurations, such as 2-way, 3-way, and 4-way valves. These options cater to specific flow control requirements in sectors like manufacturing, energy, and life sciences. ASCO’s commitment to engineering excellence ensures their valves meet stringent quality standards. They provide solutions that enhance efficiency and safety in critical processes.

Parker Hannifin: Diverse Solutions and Global Presence

Parker Hannifin stands as a global leader, providing diverse motion and control technologies. Their brass solenoid valve offerings reflect this broad expertise. Parker Hannifin engineers these valves for high performance and durability, suitable for a wide spectrum of industrial and commercial applications. The company’s extensive global network ensures widespread availability and support for its products. Parker Hannifin’s product lines encompass various types of brass solenoid valves, including general-purpose and specialized models. They design these valves to handle different media and operating conditions. This comprehensive approach allows customers to find precise solutions for their fluid control needs. Parker Hannifin’s continuous innovation drives the development of advanced valve technologies, solidifying their position as a key provider.

Burkert: Precision Engineering for Brass Solenoid Valves

Burkert Fluid Control Systems excels in precision engineering, particularly in their brass solenoid valve manufacturing. The company’s focus on accuracy and efficiency is evident in every product. Burkert employs several unique engineering principles in their brass solenoid valve manufacturing, ensuring optimal performance and longevity:

- ‘Kick and Drop’ Electronics: This feature significantly reduces electrical power consumption after the valve opens. It maintains the open position with less energy.

- Pulse Coil (Latching): This mechanism uses a short electrical pulse to switch the valve. A permanent magnet then holds the position. It requires no continuous power to maintain the state, minimizing power consumption and heat.

- Analysis Version Manufacturing: Burkert produces these valves under clean-room conditions. They are completely free of oils, fats, and silicone. This prevents media contamination.

- Explosion Protection (ATEX Versions): Specific versions are available for hazardous environments. They feature an encapsulated coil and molded cable. These are approved for use in Zone 1 or Zone 2.

- Vibration-Proof Design: The coil is bolted directly to the valve body. It is fully encapsulated in epoxy. This ensures high stability and resistance to strong vibrations.

- Abrasion Protection: PTFE sliding rings prevent metallic abrasion between the core and core guide tube. This is especially important with dry gases. It extends the valve’s service life.

- Direct-Operated Design: This design allows the valve to function effectively without a pressure differential. It suits systems like closed circulating circuits or gravity-fed systems, and even technical vacuum.

- Welded Stopper and Plunger Guide Tube: This construction enhances the pressure resistance and leak-tightness of the valve. These innovations underscore Burkert’s dedication to advanced fluid control solutions. They provide reliable and precise control for demanding applications.

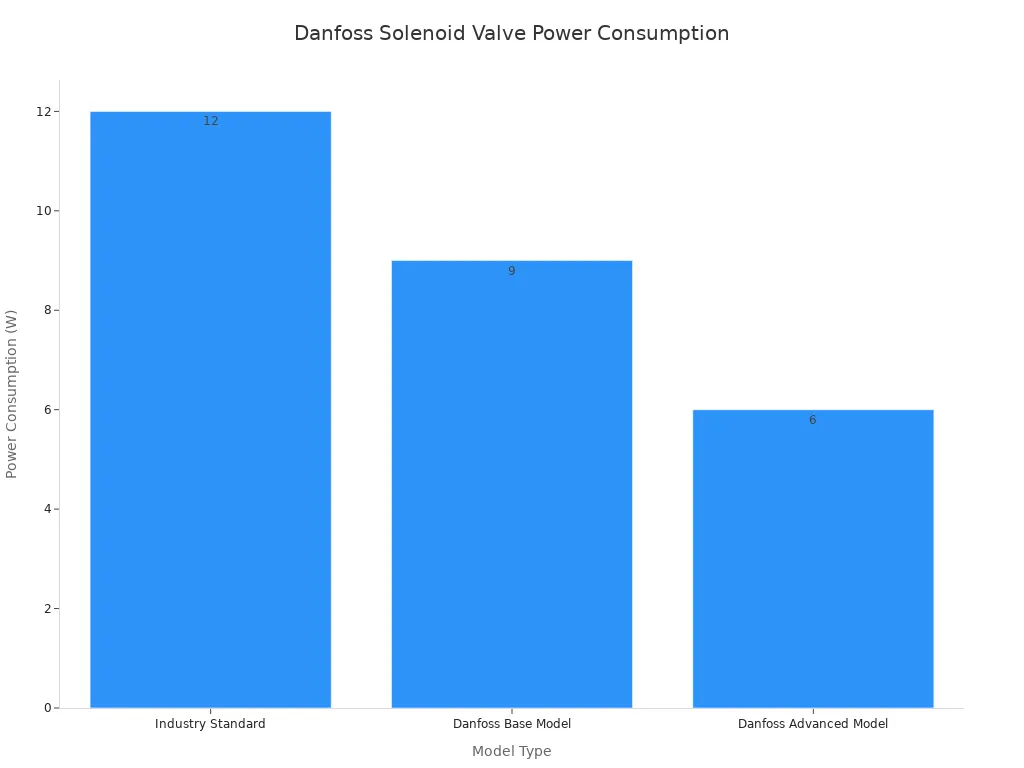

Danfoss: Energy Efficiency and Robust Brass Solenoid Valves

Danfoss leads the industry in climate and energy-efficient solutions. The company applies this extensive expertise to its brass solenoid valve production. Danfoss designs these valves for energy efficiency and robust performance across diverse applications. Their commitment to sustainability drives product development. Danfoss brass solenoid valves find use in various systems. They handle media such as compressed air, drinking water (up to 90°C), hot water (up to 140°C), technical water, and steam. This versatility makes them suitable for many industrial and commercial settings.

Danfoss prioritizes reliability and long operational life in its valve designs. They offer a range of direct-acting and servo-operated valves. This ensures precise control and efficient operation in demanding environments. Danfoss valves demonstrate significant energy efficiency. Their advanced models achieve a 50% lower energy use compared to an industry standard 12W coil. This translates into substantial operational savings.

| Model Type | Power Consumption |

|---|---|

| Industry Standard | 12W coil |

| Danfoss Base Model | 9W (IEC 60079) |

| Danfoss Advanced Model | 6W (Energy Star Certified) |

The Danfoss Solenoid Valve optimizes energy efficiency in HVAC systems. It ensures reliable performance in applications like managing cooling in commercial buildings or heating in industrial facilities.

SMC: Automation Focus and Compact Brass Solenoid Valve Designs

SMC Corporation is a world leader in pneumatic technology. The company offers a vast array of automation components, including high-quality brass solenoid valves. SMC focuses on innovation and compact designs. This allows for seamless integration into complex machinery and systems. Their brass solenoid valves are known for precision and rapid response times. SMC serves industries such as automotive, electronics, and packaging. They provide solutions that enhance productivity and efficiency.

SMC’s extensive research and development efforts ensure cutting-edge products. Their brass solenoid valves feature compact dimensions and efficient flow rates.

- Port Sizes: 1/4 to 1 inch

- Flow Rates (Cv): 1.9 to 10.2

These specifications make them highly adaptable for various applications. SMC’s global manufacturing and distribution network supports customers worldwide. They deliver reliable and technologically advanced fluid control solutions.

Norgren: Industrial Applications and Custom Brass Solenoid Valves

Norgren, a brand of IMI Precision Engineering, specializes in high-performance fluid control and motion products. Norgren engineers its brass solenoid valves for demanding industrial applications. They offer robust construction and reliable operation. The company provides customized solutions to meet specific customer requirements. Norgren’s expertise spans various sectors. These include commercial vehicles, energy, and process industries.

Their valves ensure precise control of fluids and gases. Norgren focuses on durability and performance under harsh conditions. They leverage advanced engineering to develop innovative valve technologies. This commitment to quality and tailored solutions establishes Norgren as a key player in the brass solenoid valve market.

ODE: Italian Craftsmanship in Brass Solenoid Valve Production

ODE S.r.l. stands as a prominent Italian manufacturer, specializing in solenoid valves and pumps. The company has built a strong reputation for quality and reliability. ODE designs and produces a wide range of brass solenoid valves. These valves cater to various industrial and commercial applications. Their products often feature robust construction and precise fluid control. ODE emphasizes Italian craftsmanship in its manufacturing processes. This commitment ensures high-performance and durable valves.

ODE’s brass solenoid valves find use in many sectors. These include coffee machines ☕, industrial automation, water treatment systems, and medical equipment. The company offers different valve types. These include direct-acting, pilot-operated, and proportional valves. This variety allows customers to select the best solution for their specific needs. ODE also focuses on innovation. They continuously develop new technologies. This ensures their valves meet evolving market demands. Their global distribution network supports customers worldwide. ODE provides excellent technical assistance and after-sales service.

CEME: OEM Specialization for Brass Solenoid Valves

CEME S.p.A. is another leading Italian company. They specialize in the production of solenoid valves and pumps. CEME has established itself as a key supplier for Original Equipment Manufacturers (OEMs). The company offers a comprehensive range of brass solenoid valves. They design these valves for integration into various systems and appliances. CEME’s strength lies in its ability to customize products. They meet specific customer requirements. This flexibility makes them a preferred partner for many industries.

CEME’s brass solenoid valves are known for their compact design, high performance, and long operational life. They serve diverse applications. These include home appliances 🏠, vending machines, automotive systems, and industrial machinery. The company invests heavily in research and development. This ensures their products remain at the forefront of technology. CEME maintains strict quality control standards. They guarantee reliable and consistent valve performance. Their efficient production capabilities allow them to handle large volumes. They also deliver customized solutions promptly. CEME’s dedication to quality and customer satisfaction makes them a significant player in the brass solenoid valve market.

NIBCO: High-Quality Brass Valve Manufacturing

NIBCO is a well-established American manufacturer. They produce a wide array of flow control products. The company has a long history, dating back to 1904. NIBCO offers high-quality brass valves. These include various types of solenoid valves. They design their brass products for durability and reliable performance. NIBCO serves residential, commercial, and industrial markets. Their extensive product line meets diverse plumbing and HVAC needs.

NIBCO’s commitment to quality is evident in the materials they select for their valves. For instance, their high-quality brass valves feature specific material compositions for optimal performance:

| Component | Material |

|---|---|

| Seal Material | PTFE |

| Seat Material | PTFE |

| Stem Material | Silicon Bronze |

| Ball Material | Brass with Hard Chrome Plate |

| Body Material | Bronze |

These material choices contribute to the valves’ robust construction and longevity. Key components include:

- Ball Material: Chrome plated brass

- Stem Material: Silicon bronze

- Body Material: Bronze

- Seal/Seat Material: Reinforced PTFE and Bronze

The company emphasizes stringent manufacturing processes. They ensure their valves meet industry standards. NIBCO’s commitment to quality extends to its customer support. They offer comprehensive technical resources. They also provide excellent service. Their strong distribution network ensures product availability across North America and beyond. NIBCO’s century-long experience in valve manufacturing positions them as a trusted provider of dependable solenoid valve solutions. They deliver reliable products for critical applications.

United Brass: Custom Brass Solenoid Valve Solutions

United Brass, Inc. maintains a long-standing reputation for manufacturing high-quality brass valves. The company specializes in producing durable and reliable brass products. They offer a range of brass solenoid valves. These valves meet the demands of various industrial and commercial applications. United Brass focuses on robust construction and precision engineering. This ensures their valves perform consistently in challenging environments. Their product line includes valves suitable for water, air, and light oil. They provide different port sizes and voltage options. This versatility allows customers to find appropriate solutions for specific system requirements.

United Brass provides customized solutions to meet specific customer needs. These solutions include custom valve configurations and materials for their products, such as solenoid valves. United Brass solenoid valves can also be made lead-free. They conform to federal and state lead level requirements. This includes the stricter ‘Reduction of Lead in Drinking Water Act’ mandate (effective Jan. 4, 2014). This mandate redefines ‘lead free’ as not more than a weighted average of 0.25% lead on wetted surfaces. Furthermore, United Brass offers various manufacturing options for their brass valves, including solenoid valves. These options meet market demands for faster deliveries and customer service.

United Brass emphasizes quality control throughout its manufacturing process. They use premium brass materials. This enhances the longevity and corrosion resistance of their solenoid valves. Their commitment to customer satisfaction extends to providing reliable technical support. United Brass serves industries such as plumbing, HVAC, and general industrial fluid control. Their extensive experience in brass manufacturing positions them as a trusted provider of dependable solenoid valve solutions.

VERSA Products: High-Performance Brass Solenoid Valves

VERSA Products stands as a recognized leader in manufacturing high-performance industrial valves. The company specializes in robust and reliable solenoid valves. They design these valves for demanding applications. VERSA’s brass solenoid valves are known for their exceptional durability and long service life. They engineer these products to withstand harsh operating conditions. This includes extreme temperatures and corrosive media. VERSA offers a comprehensive range of brass solenoid valves. These include 2-way, 3-way, and 4-way configurations. They also provide various actuation methods.

VERSA Products prioritizes precision and reliability in its valve designs. Their valves often feature modular construction. This simplifies maintenance and increases operational flexibility. The company serves critical industries. These include oil and gas, chemical processing, and power generation. VERSA’s commitment to engineering excellence ensures their brass solenoid valves deliver consistent performance. They meet stringent industry standards. Their global presence and extensive distribution network support customers worldwide. VERSA provides high-quality fluid control solutions for complex industrial systems.

WIC Valve: Specialized Electric Brass Solenoid Valves

WIC Valve specializes in manufacturing electric solenoid valves. The company focuses on providing reliable and cost-effective solutions. They offer a diverse range of brass solenoid valves. These valves cater to various applications. WIC Valve designs its products for precision control and efficient operation. Their brass solenoid valves are suitable for controlling air, water, oil, and gas. They provide different valve types. These include normally closed, normally open, and direct-acting models.

WIC Valve emphasizes compact designs and ease of integration. This makes their valves ideal for OEM applications and automated systems. The company maintains strict quality standards in its manufacturing processes. This ensures consistent performance and durability. WIC Valve offers a variety of port sizes and voltage options. This allows for broad applicability across different industries. Their commitment to innovation drives the development of new valve technologies. WIC Valve provides dependable and versatile brass solenoid valve solutions. They support a wide array of fluid control needs.

Ningbo SENYA: Integrated Brass Solenoid Valve Manufacturing

Ningbo SENYA Pneumatic Technology Co., Ltd. operates as a prominent integrated organization. This company manufactures and exports a wide range of pneumatic components. As a leading Chinese pneumatic component manufacturer and factory, Ningbo SENYA focuses on producing high-quality valves, cylinders, and other pneumatic-related products. They have established a strong brand reputation and possess rich industrial application experience. This expertise positions them as a top brass solenoid valve manufacturer in China.

The company excels in producing brass solenoid valves. They offer robust and reliable solutions for various industrial needs. Ningbo SENYA’s manufacturing processes integrate advanced technology. This ensures precision and durability in every product. Their commitment to quality makes them a trusted supplier. Customers rely on their valves for consistent performance in demanding environments.

Ningbo SENYA’s product portfolio includes diverse brass solenoid valve types. These valves cater to a broad spectrum of applications. They design their products for optimal fluid control and efficiency. The company’s integrated approach covers design, production, and export. This allows them to maintain strict quality control throughout the entire process. Their focus on customer satisfaction drives continuous innovation. They consistently meet evolving market demands.

Ningbo SENYA’s integrated manufacturing model ensures high-quality brass solenoid valves from design to delivery. This comprehensive approach guarantees product reliability and customer satisfaction.

The company’s extensive experience in the pneumatic industry provides a significant advantage. They understand the critical requirements of various sectors. This knowledge translates into superior product design and functionality. Ningbo SENYA serves both domestic and international markets. They provide reliable and high-performance brass solenoid valves to a global clientele. Their dedication to excellence solidifies their position as a key player in the brass solenoid valve market.

Ningbo SENYA’s brass solenoid valves offer several key advantages:

- Integrated Production: They manage the entire manufacturing process, ensuring consistent quality.

- Advanced Technology: The company utilizes modern techniques for precision engineering.

- Robust Design: Their valves withstand demanding industrial conditions.

- Diverse Applications: Products suit various industries, from automation to fluid control systems.

- Global Reach: Ningbo SENYA exports its products worldwide, supporting international clients.

This integrated approach allows Ningbo SENYA to deliver brass solenoid valves that meet high standards for performance and longevity.

Key Considerations for Choosing a Brass Solenoid Valve Supplier

Selecting the right brass solenoid valve supplier requires careful evaluation. Buyers must consider product specifications, customization capabilities, and post-purchase support. These factors ensure the chosen valve meets application demands and provides long-term reliability.

Product Specifications and Application Needs for Brass Solenoid Valves

Buyers must match valve specifications to their specific application needs. Key product characteristics include:

- Body Material: Brass

- Seal Materials: Viton®, BUNA-N, or EPDM

- End Connections: NPT Threaded (3/8″ to 1″)

- Maximum Temperature: 302°F (Viton), 176°F (BUNA)

- Maximum Pressure: Varies by model

Consider the media type and operating environment. For instance, choose seal materials based on temperature range and chemical compatibility. Nitrile rubber offers versatility, EPDM suits hot water, Viton handles high temperatures and fuels, and PTFE provides chemical resistance. Evaluate temperature and pressure requirements; metal-bodied valves work best for high heat or pressure applications like steam or hot oil. Determine the operational type: Normally Closed (NC), Normally Open (NO), or Bistable/latching valves. This depends on the desired default state during power failure and actuation frequency. Environmental factors also matter. Match the enclosure to the environment, such as NEMA 4/4X for washdown areas or NEMA 7 for hazardous locations. Finally, ensure the valve’s port size, flow rate, and connection standards align with system requirements. Direct-operated valves suit low or zero pressure, while pilot-operated valves require a minimum pressure differential for high-flow, high-pressure systems.

Customization Options for Brass Solenoid Valves

Many manufacturers offer customization options for brass solenoid valves. This allows buyers to tailor products to unique system requirements. Suppliers can provide custom-made forged brass solenoid valves, machined precisely to customer drawings. This ensures adaptability and specific functionality. Custom brass alloy components are also available. These include nuts, locknuts, valve bodies, and various connectors. OEM forged brass solenoid valves with custom machining are common. Hot-forged brass components, often in Ecobrass lead-free alloys, offer high precision and superior finish for specialized applications like vending machines. Ningbo SENYA Pneumatic, for example, tailors solutions exclusively for customers with specific product requirements.

Warranty and After-Sales Support for Brass Solenoid Valves

A strong warranty and reliable after-sales support are crucial for any brass solenoid valve purchase. A good warranty protects against manufacturing defects. Electricsolenoidvalves.com, for instance, offers a one-year warranty for their brass solenoid valves. This guarantees them free from defects in workmanship and materials under normal use from the date of purchase. Reputable suppliers provide comprehensive technical assistance. They offer guidance on installation, troubleshooting, and maintenance. This support minimizes downtime and extends the valve’s operational life.

Pricing and Value Proposition of Brass Solenoid Valves

The pricing and value proposition of brass solenoid valves depend on several key factors. Material costs and manufacturing complexity significantly influence the final price. Technological features and competitive pricing strategies also play a role.

Several elements determine a valve’s cost. High-quality brass valves are generally more expensive due to their durability and conductivity. Larger valves cost more because they require more material and complex manufacturing. The number of ports also affects the price; 2-way valves are simpler and less expensive than 3-way or 4-way valves. Valves designed for high-flow or high-pressure applications are more expensive. They need stronger materials and precise manufacturing. Specific electrical specifications, like non-standard voltage or low-power consumption, can increase costs. Well-established brands often charge a premium due to their reputation and investment in research. Valves with application-specific features, such as those for food and beverage, also cost more. Market dynamics and raw material prices, especially for metals like copper, directly impact production costs.

Supply Chain and Delivery Reliability for Brass Solenoid Valves

A robust supply chain and reliable delivery are critical for brass solenoid valve suppliers. Top manufacturers ensure efficient logistics and inventory management. This guarantees timely product availability. They minimize delays and disruptions. A dependable supply chain supports continuous operations for customers. It also reduces project timelines. Suppliers with strong global networks can deliver products consistently worldwide. This reliability builds trust and strengthens customer relationships.

Technical Expertise and Consultation for Brass Solenoid Valves

Leading suppliers offer extensive technical expertise and consultation services. They provide comprehensive support to customers. This includes assistance with valve selection and specification. They help clients choose the correct valve for their specific needs. Suppliers also offer engineering design services. These services help integrate valves into complex systems. Furthermore, they provide maintenance and repair services. This ensures the longevity and optimal performance of the valves. Some suppliers offer on-site installation and commissioning services. They also conduct training programs covering product usage, safety, and maintenance. This support ensures customers maximize the value of their brass solenoid valves.

Reputable Suppliers of Brass Solenoid Valves

Beyond the primary manufacturers, several reputable suppliers play a crucial role in distributing and supporting brass solenoid valves. These companies often offer a wide selection of products from various brands. They also provide valuable technical expertise and customer service.

Ammar Industrial

Ammar Industrial serves as a reliable supplier of brass solenoid valves. The company focuses on delivering high-quality fluid control components to diverse industries. Ammar Industrial sources products from leading manufacturers. This ensures customers receive durable and efficient valves. They maintain a comprehensive inventory. This allows for quick fulfillment of orders. Ammar Industrial also provides technical support. This helps clients select the correct valve for their specific applications. Their commitment to customer satisfaction makes them a trusted partner in the supply chain.

iPolymer

iPolymer specializes in fluid handling solutions. They offer a range of brass solenoid valves alongside their polymer-based products. The company provides valves suitable for various industrial processes. iPolymer emphasizes product quality and performance. They ensure their brass solenoid valves meet stringent industry standards. Customers benefit from iPolymer’s technical knowledge. This helps them integrate valves seamlessly into existing systems. iPolymer’s dedication to innovation and customer service strengthens its position as a key supplier.

EVSCO

EVSCO operates as a dedicated supplier of industrial valves and controls. They feature a strong selection of brass solenoid valves within their product portfolio. EVSCO partners with reputable manufacturers. This guarantees the reliability and longevity of their offerings. The company provides solutions for applications ranging from general utility to specialized industrial needs. EVSCO’s team offers expert consultation. This assists customers in making informed purchasing decisions. Their efficient distribution network ensures timely delivery. EVSCO’s focus on quality products and responsive service establishes them as a valuable resource for brass solenoid valves.

Caylor Industrial Sales, Inc.

Caylor Industrial Sales, Inc. operates as a reliable distributor of industrial products. They offer a comprehensive selection of brass solenoid valves. The company partners with leading manufacturers. This ensures customers receive high-quality and durable fluid control solutions. Caylor Industrial Sales focuses on serving various industrial sectors. These sectors include manufacturing, processing, and utilities. They maintain a robust inventory. This allows for prompt delivery and minimizes downtime for their clients. Their team possesses extensive product knowledge. They provide expert technical assistance. This helps customers choose the most suitable brass solenoid valves for their specific applications. Caylor Industrial Sales emphasizes strong customer relationships. They offer responsive service and support. This commitment makes them a trusted source for industrial valve needs.

Electric Solenoid Valves

Electric Solenoid Valves specializes in the direct supply of solenoid valves. They offer a wide array of brass solenoid valves through their online platform. The company focuses on providing accessible and cost-effective solutions. They cater to both individual buyers and businesses. Electric Solenoid Valves sources products from various manufacturers. This ensures a diverse selection of valve types and specifications. Their brass solenoid valves are suitable for controlling water, air, oil, and gas. They provide detailed product information and specifications online. This helps customers make informed purchasing decisions. The company prioritizes efficient order processing and shipping. This ensures timely delivery to their clients. Electric Solenoid Valves serves as a convenient and reliable option for acquiring brass solenoid valves.

DwyerOmega

DwyerOmega provides a broad range of instrumentation and control products. Their offerings include high-quality brass solenoid valves. The company is known for its extensive catalog and technical expertise. DwyerOmega supplies valves for diverse applications. These applications span HVAC, process control, and laboratory settings. They feature brass solenoid valves designed for precision and reliability. DwyerOmega emphasizes product quality and customer support. Their technical team assists clients with product selection and application guidance. They ensure customers integrate the valves effectively into their systems. DwyerOmega’s commitment to comprehensive solutions makes them a valuable supplier in the fluid control market.

Leading manufacturers like ASCO, Parker Hannifin, and Burkert excel in brass solenoid valve production. Specialized suppliers such as Ammar Industrial and Electric Solenoid Valves provide diverse product ranges. When selecting valves, buyers must prioritize matching product specifications to application needs. They should also consider customization options and robust after-sales support. The future landscape of brass solenoid valve technology will likely feature increased integration of smart features, enhanced energy efficiency, and sustainable material innovations.

FAQ

What are the primary advantages of brass solenoid valves?

Brass solenoid valves offer excellent corrosion resistance for water and non-acidic fluids. They are also cost-effective and durable. Manufacturers can machine brass precisely, ensuring reliable performance.

Which key criteria define excellence in brass solenoid valve manufacturing?

Excellence involves stringent quality control, continuous innovation, and proven reliability. Top manufacturers consistently meet high standards. They ensure optimal product performance in diverse applications.

Why are certifications important for brass solenoid valves?

Certifications like CE, RoHS, UL, and NSF ensure product safety, quality, and environmental responsibility. They guarantee valves meet stringent regulatory requirements. This protects users and the environment.

What should one consider when choosing a brass solenoid valve supplier?

Buyers must evaluate product specifications, customization options, and after-sales support. They should also consider warranty, pricing, and supply chain reliability. Technical expertise from the supplier is also crucial.