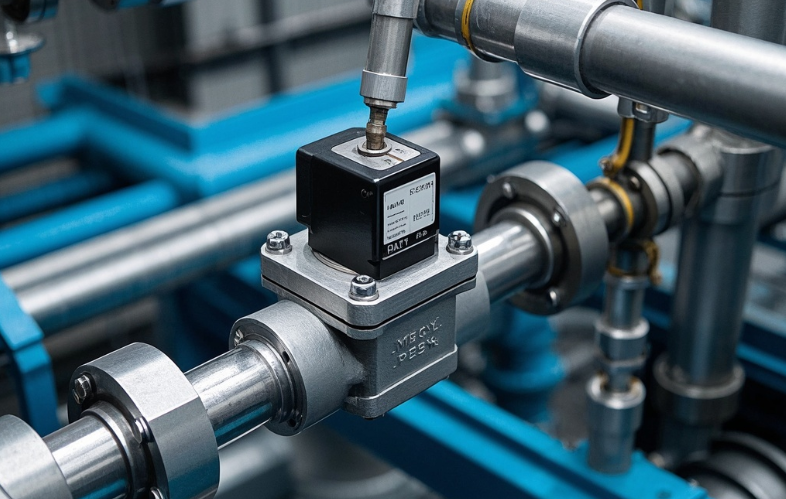

Selecting a brass solenoid valve requires careful consideration of several critical factors to ensure optimal performance and longevity. The primary factors include the fluid type, operating pressure, temperature range, and valve size. Understanding these elements is crucial for reliable and efficient system operation. For example, the application fields of brass solenoid valve vary widely, making the selection points of brass solenoid valve essential to address specific needs. Consider how to select a suitable brass solenoid valve according to the pressure; this is vital for optimal functionality. Furthermore, understanding which scenarios are high-precision brass solenoid valves suitable for guides precise selection. The selection of brass solenoid valve under different pressures also demands careful attention.

Key Takeaways

- Match the valve to the fluid. Check the fluid type, temperature, and if it has particles. This prevents damage and ensures the valve works well.

- Consider how the valve will operate. Look at system pressure, how much fluid needs to flow, and how often the valve will turn on and off. This helps the valve last longer.

- Understand the electrical needs. Make sure the valve’s voltage and power match your system. Also, check the coil’s heat rating for safety.

- Choose the right valve design. Decide if you need a normally open or normally closed valve. Also, pick the right seal material for your fluid.

- Think about the environment. If the area is dangerous or needs quiet, choose a valve with special certifications. Regular checks also keep the valve working well.

Fluid Compatibility for Brass Solenoid Valve Selection

Type of Fluid and Chemical Composition

Selecting the correct brass solenoid valve begins with understanding the fluid it will control. The fluid’s chemical composition directly impacts the valve’s longevity and performance. Manufacturers do not recommend brass solenoid valves for highly corrosive substances. Certain chemical compositions can degrade brass materials over time. These include:

- Acidic environments

- Acidic fluid media

- Alkaline water

Always verify the fluid’s compatibility with brass and the valve’s seal materials to prevent premature wear or failure.

Fluid Temperature Range Considerations

Fluid temperature is another critical factor for valve selection. Each valve has specific minimum and maximum operating temperatures. Exceeding these limits can damage the valve’s internal components, especially the seals. For example, a 3/4 inch brass normally closed solenoid valve typically operates within a range of 15°F (-10°C) to 250°F (120°C). Another valve series, like SBSV-B, handles temperatures from 32°F to 149°F. Always match the valve’s temperature rating to the application’s fluid temperature range.

Fluid Viscosity and Flow Characteristics

Fluid viscosity significantly influences the flow rate and pressure drop across a solenoid valve. Higher viscosity increases the fluid’s internal resistance, causing a greater pressure drop within the valve body. This also results in slower flow rates and response times. Conversely, low-viscosity fluids flow more smoothly, leading to minimal pressure drop and faster valve response. Standard solenoid valves typically handle fluids with viscosities up to 40 or 50 cSt. Higher viscosities can cause issues like blocked pilot holes. For highly viscous media (above 50 cSt), specialized coaxial solenoid valves are engineered to handle these conditions effectively, allowing for high flow rates with minimal pressure loss.

| Characteristic | Low-Viscosity Fluids | High-Viscosity Fluids |

|---|---|---|

| Response Time | Faster | Slower |

| Power Usage | Lower | Higher |

| Pressure Drop | Minimal | Increased |

| Flow Rate | Smooth, higher | Slow-moving, lower |

| Erosion | Minimal | Increased |

| Standard Valve Suitability | Suitable (up to 40-50 cSt) | Issues (blocked pilot holes) |

| Coaxial Valve Suitability | N/A | Ideal (above 50 cSt) |

Presence of Particulates and Filtration Needs

The presence of solid particulates in the fluid significantly impacts a brass solenoid valve’s performance and lifespan. Dirt, rust, scale, or other debris can cause several issues. These issues include:

- Clogging: Small particles can block the valve’s internal passages, especially the pilot holes in pilot-operated valves. This prevents proper valve operation.

- Wear and Tear: Abrasive particles can erode internal components, such as the valve seat and seals. This leads to leaks and reduced efficiency.

- Malfunction: Debris can prevent the valve from fully opening or closing. This compromises system control and safety.

To mitigate these risks, proper filtration is essential. Installing a suitable filter upstream of the solenoid valve protects it from harmful contaminants. The required filtration level depends on the valve’s design and the fluid’s cleanliness. For instance, pilot-operated valves typically require finer filtration than direct-acting valves due to their smaller internal orifices.

Consider the following when determining filtration needs:

- Particle Size: Identify the maximum particle size the fluid may contain.

- Valve Orifice Size: Match the filter’s micron rating to the smallest orifice within the valve.

- Fluid Cleanliness Standards: Adhere to any industry-specific cleanliness requirements for the fluid.

Implementing effective filtration extends the valve’s service life. It also ensures reliable operation and reduces maintenance costs. Neglecting filtration can lead to frequent valve failures and system downtime.

Operating Conditions for Brass Solenoid Valve Performance

System Pressure and Pressure Differential

System pressure is a critical factor when selecting a brass solenoid valve. Engineers must ensure the valve’s pressure rating matches or exceeds the application’s maximum operating pressure. The pressure differential, the difference between upstream and downstream pressure, also affects valve operation. Some valves require a minimum pressure differential to function correctly, especially pilot-operated types. Valcor Engineering Corporation offers brass solenoid valves with varying pressure ratings for industrial applications. Their general-purpose solenoid valves, made of brass, handle pressure ranges from vacuum to over 1000 PSI. Specifically, the SV330/430 series, which can be brass, has an operating pressure range of 0 psi to 1050 psi. Other brass options include the SV321/421 series with a pressure rating up to 250 psi, and the SV320/420 series with a pressure rating up to 200 psi.

Flow Rate Requirements and Orifice Sizing

The required flow rate dictates the necessary orifice size of the brass solenoid valve. The orifice diameter is the primary factor determining a solenoid valve’s flow coefficient (Cv). Cv is a standardized metric representing flow capacity. It indicates how many U.S. gallons per minute of water at 60°F flow through a valve with a 1 psi pressure drop. To select the correct valve, engineers calculate the required flow coefficient (Cv) based on the target flow rate, available pressure drop (ΔP), and fluid properties. They then select a valve with a Cv value equal to or slightly greater than this calculated requirement. For liquids, the flow rate (Q) relates to Cv, pressure drop, and specific gravity. For gases, a different formula applies, considering upstream and downstream pressures, temperature, and specific gravity.

Ambient Temperature Impact on Brass Solenoid Valve

Ambient temperature significantly affects the performance and lifespan of a brass solenoid valve. Extreme temperatures can cause various issues. High-temperature environments can soften or deform seals, and coils may overheat. Continuous use or high cycling generates heat, which, combined with ambient heat, can damage elastomers and electrical components. Extreme heat alters the molecular structure of rubber or synthetic polymer elastomers, accelerating aging and making seals less flexible and prone to cracking. Heat also increases the coil’s resistance, requiring more voltage for operation. Insufficient voltage can lead to improper valve actuation.

Conversely, freezing conditions can also cause problems. Residual moisture in the valve body may expand, causing cracking or blockage. Extremely cold temperatures can reduce seal elasticity, making them brittle and potentially causing leaks or failure. Metals and elastomers contract in cold temperatures, which negatively affects a valve’s sealing ability. Cold temperatures can prevent elastomer seals from compressing properly, leading to slower actuation, especially in low-cycling applications.

Duty Cycle and Expected Lifespan

The duty cycle of a brass solenoid valve describes how often and how long the valve operates within a given period. This factor directly influences the valve’s expected lifespan. Continuous operation, or a high duty cycle, places more stress on internal components. This includes the coil and seals. Consequently, valves operating continuously often have a shorter lifespan compared to those used intermittently. Manufacturers design valves for specific duty cycles. Matching the valve to the application’s duty cycle prevents premature failure.

The expected lifespan of a solenoid valve is typically measured in cycles. A cycle represents one complete opening and closing action. Different valve types and operating conditions yield varying lifespans.

| Valve Type / Condition | Expected Lifespan (Cycles) |

|---|---|

| General Brass Valves (dry air/gas) | Up to 20 million |

| Brass 8210Q Series | 5 million |

| Brass 8262Q Series | 20 million |

| Industrial Solenoid Valve (continuous operation) | 1 million to 10 million |

| Universal Solenoid Valve | 1 million to 10 million |

| Normal Working Environments | 1 million to 5 million |

| Excellent Conditions | Tens of millions |

As the table illustrates, a general brass valve handling dry air or gas can achieve up to 20 million cycles. However, industrial solenoid valves in continuous operation typically offer 1 million to 10 million cycles. Valves operating under excellent conditions can even reach tens of millions of cycles. Factors like fluid cleanliness, temperature, and pressure also affect the actual lifespan. Selecting a valve with a robust design and appropriate materials for the intended duty cycle ensures long-term reliability. This minimizes maintenance and replacement costs.

Electrical Specifications for Brass Solenoid Valve Control

Voltage and Frequency Compatibility

Selecting the correct electrical specifications for a brass solenoid valve is crucial for its proper operation. Engineers must match the valve’s voltage and frequency ratings to the available power supply. Different regions and countries use various electrical standards. For example, Japan and North Korea typically use 100V, while the United States and Canada operate on 110-130V. Many European and Asian countries, including the UK, Germany, and China, utilize 220-230V. Frequency also varies, with 50 Hz common in Europe and Asia, and 60 Hz prevalent in North America.

| Region/Country | Voltage (V) | Frequency (Hz) |

|---|---|---|

| Japan, North Korea | 100 | – |

| Taiwan, United States, Canada, Panama, Cuba, Lebanon, Mexico | 110-130 | – |

| UK, Germany, France, China, Singapore, Hong Kong (200V), Italy, Spain, Greece, Austria, Netherlands, Philippines, Thailand, Norway, India, New Zealand, Australia | 220-230 | – |

| United States | 120/240 (single phase), 208/240 (three phase) | 60 |

| Germany | 230 (single phase), 380 (three phase) | 50 |

Power Consumption and Energy Efficiency

The power consumption of a brass solenoid valve directly impacts overall system energy efficiency. Several factors influence how much power a valve uses.

- Size of Solenoid Valve: Larger valves require more current. Their bigger solenoids generate the necessary magnetic field and force to operate the plunger. Oversized valves can also increase flow rates beyond design capacity. This further increases power demand and draws excess, unnecessary energy.

- Peak Current Requirements: Solenoid valves need a brief surge of current to magnetize the electromagnetic system. This peak current is typically higher than the holding current. It significantly influences total energy consumption. The valve’s design and size determine these requirements. Larger valves draw more power. Inadequate peak current supply can lead to energy waste and system malfunctions.

- Solenoid Valve Design: The specific design of a solenoid valve plays a role in its energy consumption. Different designs meet various flow control needs.

Electrical Connection Type and Standards

The electrical connection type ensures secure and reliable power delivery to the brass solenoid valve. Standardized connectors simplify installation and maintenance. DIN 43650 connectors are common in industrial applications. These connectors come in different forms.

| Connector Type | Contact Pitch (mm) | Common Reference | Standard | Pole Options |

|---|---|---|---|---|

| DIN 43650 Form A | 18 | Largest | EN 175301-803-A | 2-pole or 3-pole + earthing |

| DIN 43650 Form B | 10 (EN) / 11 (Industry Standard) | Miniature | EN 175301-803-B or Industry Standards | 2-pole + grounding |

| DIN 43650 Form C | 8 (EN) / 9.4 (Industry Standard) | Subminiature | EN 175301-803-C or Industry Standards | 2-pole or 3-pole + ground |

Material options for DIN valve connectors commonly include stainless steel, carbon steel, and brass. Manufacturers choose these materials based on the working environment and media. Stainless steel suits corrosive media. Carbon steel works for general industrial applications.

Coil Insulation Class and Response Time

The coil insulation class of a brass solenoid valve is a critical electrical specification. It indicates the maximum temperature the coil’s insulation material can withstand without degrading. This rating directly affects the valve’s reliability and lifespan, especially in high-temperature environments. Different insulation classes correspond to specific temperature limits. For example, Class F insulation tolerates temperatures up to 155°C (311°F), while Class H handles up to 180°C (356°F). Selecting a valve with an appropriate insulation class prevents coil burnout and ensures consistent performance. Engineers must match the coil’s insulation class to the expected ambient and operating temperatures of the application.

| Insulation Class | Max Temperature (°C) | Max Temperature (°F) |

|---|---|---|

| Class A | 105 | 221 |

| Class B | 130 | 266 |

| Class F | 155 | 311 |

| Class H | 180 | 356 |

Response time refers to the speed at which a solenoid valve opens or closes after receiving an electrical signal. This factor is crucial for applications requiring precise timing and rapid control. Several elements influence a valve’s response time. The valve’s design, whether direct-acting or pilot-operated, plays a significant role. Direct-acting valves generally offer faster response times because the solenoid directly moves the seal. Pilot-operated valves, which use system pressure to assist in opening or closing, typically have slightly slower response times. Fluid viscosity, system pressure, and the power of the solenoid coil also affect how quickly the valve reacts. Applications like pneumatic systems or precise dosing often demand valves with very fast response times to maintain operational accuracy.

Brass Solenoid Valve Design and Material Choices

Port Size and Connection Type Options

The physical design of a brass solenoid valve includes its port size and connection type. These features ensure proper integration into a piping system. A common configuration features a 3/8″ Female NPT port with lead wires for the coil connection. Threaded ports are standard. NPT (National Pipe Taper) threads are prevalent in North America. They have a 60° thread angle and often need sealant. BSP (British Standard Pipe) threads are common internationally. BSPP is parallel, and BSPT is tapered. Mixing NPT and BSP without an adapter can cause problems. Electrical connections also vary. The DIN 43650A (3-prong) connector is frequently used for solenoid valve coils. It features screw terminals for easy installation. Product pages specify the DIN type and enclosure rating, such as IP65 / NEMA 4.

| Feature | Detail |

|---|---|

| Port Size | 3/8″ Female NPT |

| Coil Connection | Lead Wires |

- Threaded Ports:

- NPT (National Pipe Taper) threads: Common in North America, tapered with a 60° thread angle, typically requiring sealant.

- BSP (British Standard Pipe) threads: Common internationally, with a 55° angle. BSPP is parallel, and BSPT is tapered. Mixing NPT and BSP without an adapter can cause issues.

- Electrical Connections:

- DIN 43650A (3-prong) connector: Frequently used for solenoid valve coils, featuring screw terminals for easy installation. Product pages often specify the DIN type and enclosure rating (e.g., IP65 / NEMA 4).

Orifice Size and Flow Capacity

The orifice size directly determines a brass solenoid valve’s flow capacity. A larger orifice allows more fluid to pass through. For example, a 3/4″ brass solenoid valve with a 20mm orifice size has a high flow rate. It achieves approximately 58 GPM at 60 PSI, with a Cv value of 7.6. This directly demonstrates that a larger orifice size contributes to a higher flow capacity. Another example shows an orifice of 0.385 inches (9.78 mm) yields a Flow Coefficient (Cv) of 2.67. A 20 mm orifice can provide a Cv value of 9.25 gal/min. Engineers select the appropriate orifice size based on the required flow rate for the application.

| Characteristic | Value |

|---|---|

| Orifice size | 20 mm |

| Cv value | 9.25 gal/min |

| Characteristic | Value |

|---|---|

| ESEOD (orifice) | 0.385 in (9.78 mm) |

| Flow Coefficient (Cv) | 2.67 |

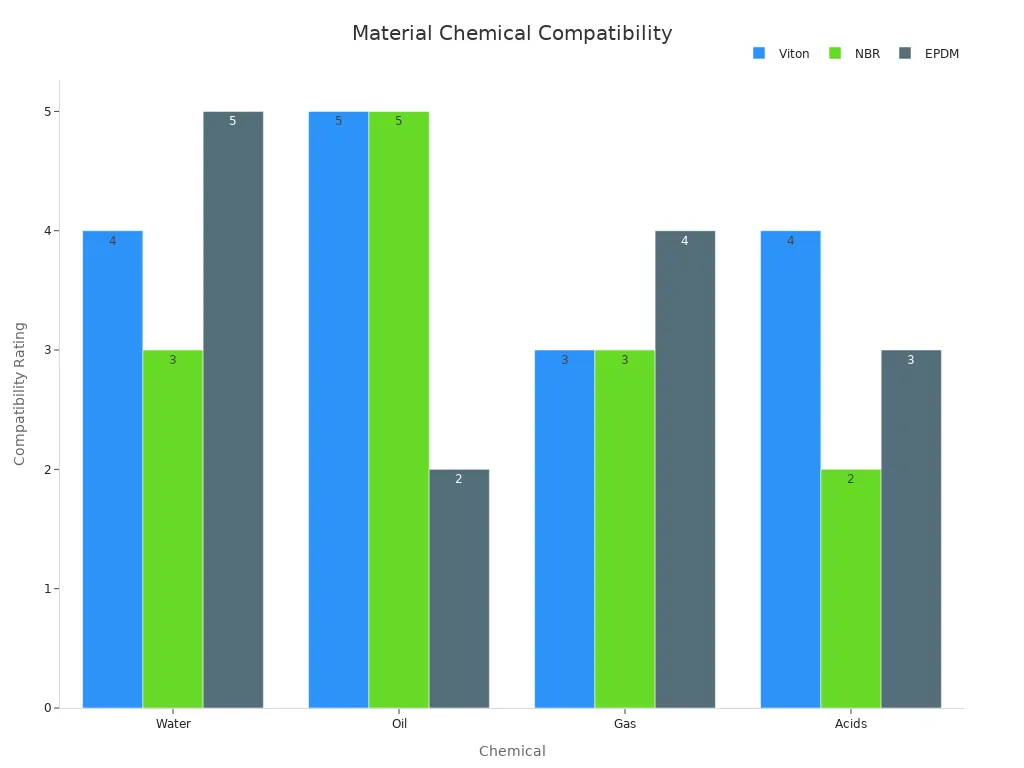

Seal Material Compatibility (NBR, EPDM, Viton)

Seal material compatibility is crucial for the valve’s longevity and performance. The fluid type dictates the best seal material. Common options include NBR, EPDM, and Viton.

| Material | Water | Oil | Gas | Acids |

|---|---|---|---|---|

| Viton | Good | Excellent | Fair | Good |

| NBR | Fair | Excellent | Fair | Poor |

| EPDM | Excellent | Poor | Good | Fair |

Nitrile rubber (NBR) resists petroleum oils, hydraulic fluids, and water. Viton offers superior resistance to a broader range of harsh chemicals. These include acids, various oils, gases, and halogenated hydrocarbons. NBR suits general chemical resistance. Viton is preferred for aggressive chemical processing, such as in automotive applications. EPDM excels with water but performs poorly with oils.

Valve Operation: Normally Open vs. Normally Closed

The operational state of a brass solenoid valve, whether normally open (NO) or normally closed (NC), significantly impacts system design. A normally closed valve remains shut when de-energized. It opens only when electricity flows through its coil. This design is common for safety applications, preventing fluid flow during power outages. Conversely, a normally open valve stays open when de-energized. It closes only when the coil receives power. This configuration is useful for applications requiring continuous flow unless specifically interrupted.

Normally open brass solenoid valves are particularly effective in certain applications:

- They work well for water, air, and non-corrosive liquid applications.

- Engineers design them for low-pressure systems, typically up to 150 PSI.

- They are suitable for non-explosive liquids.

Choosing between normally open and normally closed depends on the system’s default state requirement and safety protocols.

Actuation Method: Direct Acting vs. Pilot Operated

The actuation method of a brass solenoid valve determines how it opens and closes. Direct-acting valves and pilot-operated valves function differently. A direct-acting valve uses the solenoid coil’s magnetic force to directly lift the plunger and open the orifice. This design provides immediate control. Pilot-operated valves, however, use a small pilot orifice to leverage the system’s line pressure. This pressure then moves a larger diaphragm or piston, opening the main orifice. Pilot-operated valves require a minimum pressure differential to function.

Here is a comparison of their performance features:

| Feature | Direct-Acting Solenoid Valves | Pilot-Operated Solenoid Valves |

|---|---|---|

| Response Time | Rapid response times, immediate control | Slower response times |

| Flow Rates | Handle lower flow rates | Handle larger flow rates |

| Energy Consumption | Consume more energy | More energy-efficient, consume less energy |

| Actuation | Solenoid coil directly moves plunger | Leverages line pressure for actuation, requires minimum pressure differential |

| Pressure Environments | Suitable for low and high-pressure environments | Unsuitable for low-pressure scenarios |

| Applications | Quick operation, precise control (e.g., car wash systems) | Large fluid volumes, long-term operations (e.g., municipal water supply) |

Both types can integrate with proportional solenoids for precise flow rate adjustments. Engineers select the actuation method based on required flow rates, response time, and available system pressure.

Environmental and Application-Specific Factors for Brass Solenoid Valve

Hazardous Location Certifications (ATEX, NEMA)

Selecting a brass solenoid valve for hazardous locations demands specific certifications. These certifications ensure the valve operates safely in potentially explosive atmospheres. ATEX certification indicates solenoid valves are safe for fluid control in such environments. They are suitable for regulating flammable gases and vapors. An apparatus must be certified for the specific Zone, Class/Division, and hazardous area location where technicians install the valve. NEMA ratings determine suitable environments for electrical enclosures, relating to solenoid valve casings. These ratings specify protection standards against elements like moisture and dust. For instance, ASCO 551 Solenoid Valves (Spool) made of brass can be NEMA certified, confirming that brass solenoid valves can indeed carry this important certification.

Corrosive Environment Resistance

The environment’s corrosiveness significantly influences the choice of a brass solenoid valve. Brass solenoid valves are suitable for non-aggressive fluid service. They perform well in pipelines handling regular water and are effective with non-acidic fluids. These valves are ideal for low to medium-pressure and temperature applications. Brass resists corrosion well, especially in water and mild chemicals. However, brass can suffer from dezincification, particularly if it contains over 15% zinc. Exposure to chlorides can also cause brass valve corrosion. Acidic environments lead to brass valve corrosion, making them unsuitable for such applications.

Noise Level Requirements for Sensitive Applications

Noise levels are a crucial consideration for brass solenoid valves in sensitive applications. Some environments, like hospitals, laboratories, or residential areas, require minimal operational noise. The valve’s design and actuation method directly influence the noise it produces. Direct-acting valves often operate with less noise than pilot-operated valves, which can create a distinct “click” during actuation. Engineers must evaluate the application’s noise tolerance and select a valve designed for quiet operation. Manufacturers often provide noise specifications, helping users choose the most suitable valve for their specific needs.

Industry Certifications and Standards (e.g., NSF)

Industry certifications and standards play a vital role in selecting brass solenoid valves, especially for applications involving potable water. These certifications assure users of the valve’s safety, quality, and compliance with specific regulations. For instance, valves used in drinking water systems must meet stringent requirements.

Key certifications for brass solenoid valves in potable water applications include:

- NSF certifications for potable water applications.

- Compliance with the EPA’s Safe Drinking Water Act Section 1417 low lead requirements.

- UL Listing certification.

- NSF 372 compliant.

- Compliance with U.S. Safe Drinking Water Act (SDWA) Section 1417.

These standards ensure the valve materials do not contaminate the water and that the valve performs reliably. Manufacturers often obtain these certifications to demonstrate their commitment to public health and safety. Selecting a certified valve helps maintain system integrity and meets regulatory obligations.

Maintenance and Serviceability of Brass Solenoid Valve

Proper maintenance and serviceability are crucial for extending the lifespan and ensuring the reliable operation of brass solenoid valves. Regular inspections help identify wear and potential failures before they become critical issues.

Maintenance schedules should include:

- Checking for dirt or corrosion buildup under the diaphragm.

- Inspecting the coil for any signs of damage.

- Ensuring the flow direction matches the valve body parameters.

The frequency of checking brass solenoid valves depends on the application and its performance history. Consider these questions to determine maintenance frequency:

- If the valve fails, does a risk of safety hazards exist?

- If the valve fails at the worst possible time, what are the consequences?

- How much will it cost to eliminate the consequences of a valve failure, including lost productivity and repair/replacement?

- How much does it cost to service a valve, including time and resources?

A preventive maintenance plan ensures longevity for brass solenoid valves. This plan includes:

- Visual inspections for corrosion, leakage, or unusual wear.

- Functional testing to verify actuation timing and responsiveness.

- Leak checks and cycle testing.

- Logging all maintenance activity to identify patterns or recurring issues.

- Pre-scheduled replacement of seals or diaphragms, based on usage cycles or time intervals.

Maintenance intervals can range from monthly to quarterly, depending on the application’s demands.

Selecting the appropriate brass solenoid valve requires careful evaluation. Engineers must consider fluid characteristics, operating conditions, electrical specifications, valve design, and environmental factors. This comprehensive approach ensures reliable and efficient system operation. It effectively balances performance, cost, and longevity. Proper selection leads to long-term system efficiency and safety.

FAQ

What fluids are suitable for brass solenoid valves?

Brass solenoid valves work well with non-aggressive fluids. They are ideal for regular water and non-acidic liquids. However, manufacturers do not recommend them for highly corrosive substances. Always verify fluid compatibility with brass and seal materials to prevent premature wear.

Why is the pressure differential important for pilot-operated valves?

Pilot-operated valves require a minimum pressure differential to function correctly. This difference between upstream and downstream pressure helps move the internal diaphragm or piston. Without sufficient pressure differential, the valve may not open or close as intended, affecting system control.

What is the main difference between normally open and normally closed valves?

A normally closed valve remains shut when de-energized; it opens only with electricity. Conversely, a normally open valve stays open when de-energized. It closes only when the coil receives power. System design and safety needs determine the choice.

How does ambient temperature impact a brass solenoid valve’s lifespan?

Extreme ambient temperatures can significantly reduce a valve’s lifespan. High heat can degrade seals and overheat coils, while freezing conditions can cause cracking or reduce seal elasticity. Matching the valve’s temperature rating to the environment ensures reliability.

What certifications are crucial for brass solenoid valves in potable water applications?

For potable water applications, certifications like NSF are crucial. These standards ensure valve materials do not contaminate drinking water. Compliance with the EPA’s Safe Drinking Water Act (SDWA) Section 1417 low lead requirements is also vital. These certifications guarantee safety and regulatory adherence.