The demand for brass solenoid valve solutions is on the rise, fueled by advancements in industrial automation and infrastructure development. The global market for these valves was valued at USD 1.21 billion in 2021 and is projected to hit USD 1.63 billion by 2029, demonstrating a compound annual growth rate of 3.80% over the forecast period. This robust growth underscores significant market trends of brass solenoid valve solutions. The future of this market is clearly leaning towards smart, efficient, and sustainable options. For instance, a quick-response brass solenoid valve significantly boosts operational speed. The characteristics of high-efficiency brass solenoid valve designs are becoming increasingly vital across diverse applications, including those expertly provided by SENYA solenoid valve products. For those seeking reliable options, exploring brand recommendations for brass solenoid valve manufacturers like SENYA is highly advisable.

Key Takeaways

- The market for brass solenoid valves is growing. This is because factories use more machines and cities build new things.

- New brass solenoid valves are smarter. They can connect to the internet and save energy.

- Brass solenoid valves are now used in new places. These include smart homes, green energy, and hospitals.

- Making brass solenoid valves faces challenges. These include unstable prices for materials and other types of valves.

- Companies should invest in new ideas. They should also use green ways to make products and get materials from many places.

Key Growth Drivers for the Brass Solenoid Valve Market

The brass solenoid valve market experiences robust expansion due to several significant factors. These drivers stem from global industrial shifts and technological advancements, creating consistent demand for reliable fluid control solutions.

Industrial Automation Expansion

Industrial automation stands as a primary catalyst for the increasing demand for brass solenoid valves. Industries worldwide are integrating automation technologies to enhance operational efficiency, safety, and precision in fluid control. This includes sectors such as oil and gas, water treatment, pharmaceuticals, and manufacturing. Automated solenoid valves play a crucial role in process industries, enabling remote control of hazardous or high-pressure fluids. This minimizes human intervention and maximizes safety for workers.

The adoption of Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) systems in factory automation further drives the need for solenoid valves. These valves must integrate seamlessly for real-time data exchange, improved diagnostics, and centralized control. Leading companies are advancing solenoid valve technology to align with Industry 4.0 requirements. They offer IoT-compatible valves that support digital communication protocols. These smart solenoid valves provide enhanced control, monitoring, and predictive maintenance capabilities. The rising need for energy efficiency, compact design, and compatibility with various automation systems makes brass solenoid valves key components in next-generation industrial automation systems.

Infrastructure Development Projects

Global infrastructure development projects significantly contribute to the growth of the brass solenoid valve market. Governments and private entities are investing heavily in modernizing and expanding urban and rural infrastructure. This includes water supply and treatment systems, wastewater management, and smart city initiatives. Brass solenoid valves are essential in these projects for controlling water flow, managing irrigation systems, and ensuring efficient operation of public utilities. Their durability and corrosion resistance make them suitable for long-term use in diverse environmental conditions. As cities become smarter and more interconnected, the demand for reliable and efficient fluid control components in these large-scale projects continues to rise.

Increasing Demand in HVAC Systems

The Heating, Ventilation, and Air Conditioning (HVAC) sector represents another vital growth driver for brass solenoid valves. Modern HVAC systems require precise control over refrigerant and water flow to maintain optimal indoor climates and energy efficiency. Brass solenoid valves are integral to these systems, regulating the flow of various fluids in chillers, boilers, and air handling units. The global push for energy-efficient buildings and sustainable climate control solutions directly translates into higher demand for advanced valve technologies. As consumers and businesses prioritize comfort and lower energy consumption, the integration of sophisticated control mechanisms, including high-performance brass solenoid valves, becomes indispensable in new installations and system upgrades.

Technological Advancements in Brass Solenoid Valves

The brass solenoid valve market experiences continuous innovation. These advancements focus on improving performance, durability, and efficiency. Manufacturers integrate cutting-edge technologies to meet evolving industrial demands.

Integration of IoT and Smart Features

The integration of IoT and smart features transforms brass solenoid valves. These smart valves offer remote monitoring and control from any location. This capability significantly enhances efficiency in various processes, including manufacturing, oil and gas, and agriculture. Embedded sensors and advanced algorithms enable self-diagnosis and self-regulation. This leads to continuous optimization and improved operational efficiency. Smart features also lower maintenance costs. They identify and address issues proactively, preventing costly downtime.

Manufacturers are integrating bi-stable solenoid valves with IoT technologies. They use Low-Power Wide-Area Network (LPWAN) technologies, such as LoRa and NB-IoT, for remote monitoring and control. These technologies allow for real-time data collection and analysis. Research also focuses on predicting failures and improving reliability through data-driven predictive methods for useful life. Engineers investigate early detection of coil failure. They conduct failure mechanism studies using thermal-structure finite element methods. This ensures enhanced overall system reliability and predictive maintenance.

Advanced Materials for Brass Solenoid Valve Durability

Advancements in materials significantly improve the durability of brass solenoid valves. Manufacturers develop new brass alloys with enhanced resistance to corrosion, wear, and extreme temperatures. These materials extend the lifespan of valves, especially in harsh operating environments. For example, specialized coatings and surface treatments further protect valves from chemical degradation and abrasion. This reduces the need for frequent replacements and maintenance. The use of high-performance elastomers for seals and O-rings also contributes to better sealing integrity and longer service life. These material innovations ensure valves maintain optimal performance under demanding conditions.

Energy Efficiency Enhancements in Brass Solenoid Valves

Energy efficiency is a critical focus in the development of brass solenoid valves. New designs aim to reduce power consumption without compromising performance. Double coil technology is one such innovation. It uses two windings: a high-power winding for opening the valve and a low-power winding for holding it open. This design reduces electricity consumption by 75% for holding the valve. Energy-saving coil designs also optimize coil operation. They significantly reduce power consumption, even in single-coil conventional valves. These designs can reduce excitation current by 95% after initial activation. Next-generation low-power solenoid valves are rated at 0.5 to 0.75 watts. These designs are approaching the half-watt mark. This leads to substantial energy savings and reduced installation costs through methods like bus bars. These advancements make brass solenoid valves more environmentally friendly and cost-effective to operate.

Emerging Opportunities for Brass Solenoid Valves

The market for solenoid valves is expanding into new and diverse sectors. These emerging opportunities highlight the versatility and critical role of these fluid control components in modern technological advancements.

New Applications in Smart Homes

Smart home technology is rapidly expanding, creating significant new applications for solenoid valves. These devices enable advanced automated water management systems. For instance, a brass solenoid valve can automatically shut off the main water supply upon detecting a leak, preventing costly damage. Smart irrigation systems utilize them for precise, zone-specific watering schedules, optimizing water usage and promoting conservation. Furthermore, solenoid valves contribute to efficient climate control systems by regulating the flow of refrigerants or heating fluids. Homeowners benefit from enhanced convenience, improved energy efficiency, and greater peace of mind through these integrated solutions. The demand for reliable and compact fluid control components in residential automation continues to grow.

Growth in Renewable Energy Sectors

The renewable energy sector presents substantial growth opportunities for solenoid valves. These valves play a crucial role in various green technologies. In solar thermal systems, they precisely control the flow of heat transfer fluids, maximizing energy capture and distribution. Emerging hydrogen fuel cell applications rely on them for managing gas flow with high accuracy and safety. Geothermal energy systems also incorporate these valves for efficient fluid circulation. These applications demand components with high precision, reliability, and resistance to diverse operating conditions. Solenoid valves ensure efficient energy conversion, storage, and distribution, supporting the global transition to sustainable energy sources. Their robust design supports long-term operation in these critical infrastructure projects.

Expansion in Medical and Pharmaceutical Industries

The medical and pharmaceutical industries represent a vital area of expansion for solenoid valves. These sectors require extremely precise and sterile fluid control for various critical processes. Solenoid valves are essential for accurate dispensing of reagents and active pharmaceutical ingredients in laboratories and manufacturing. They meticulously control gases in medical diagnostic equipment, ventilators, and anesthesia machines. Sterilization processes for medical instruments and drug production also utilize these valves to manage steam or other sterilizing agents. The industry demands components that meet stringent purity standards, offer exceptional accuracy, and ensure unwavering reliability. These valves directly contribute to patient safety, product integrity, and the development of advanced medical devices and life-saving pharmaceuticals.

Challenges and Risks in the Brass Solenoid Valve Market

The market for these valves faces several significant hurdles. These challenges can impact production, profitability, and market share for manufacturers.

Supply Chain Volatility

Supply chain volatility presents a major risk for manufacturers. The solenoid valve market depends heavily on raw materials. This makes it vulnerable to price instability. Geopolitical tensions, trade restrictions, or economic instability directly affect production expenses and profit margins. A significant reliance on specific regions, particularly Asia, for material sourcing and manufacturing introduces risks related to trade policies and tariffs. Global events, such as the COVID-19 pandemic, caused initial disruptions in supply chains and manufacturing. This led to temporary setbacks in market growth. Reduced end-user demand in industries like food and automotive also occurred. Decreased operating hours due to government-mandated closures further impacted operations. The decline in crude oil demand negatively affected the market, as these valves are widely used in the oil and gas sector. Ongoing global events continue to cause delays, with 40% of manufacturers reporting supply chain interruptions in the past year.

Competition from Alternative Materials

Alternative materials pose significant competition to brass in valve manufacturing. Each alternative offers distinct advantages for specific applications.

| Material | Key Advantages | Suitable Applications |

|---|---|---|

| Stainless Steel | Superior resistance to high pressures, extreme temperatures, corrosive substances | Chemical and petrochemical industries, food and beverage, pharmaceutical, marine, outdoor |

| Aluminum | Lightweight, cost-effective | Low-pressure applications, pneumatic systems |

| Plastic (PVC/Polypropylene) | Excellent chemical resistance | Aggressive chemicals, ultrapure water systems, food and beverage, pharmaceutical |

These alternatives can offer better performance or cost-effectiveness in certain environments. This encourages manufacturers to diversify their material offerings.

Raw Material Price Fluctuations

Raw material price fluctuations directly impact production costs and profit margins. Volatility in the cost of raw materials, such as stainless steel, makes it challenging for manufacturers to maintain consistent product pricing strategies. These price changes affect manufacturing costs and the pricing strategies companies adopt. Effective management of these fluctuations is crucial to avoid business risks associated with uncontrollable price shifts. To maintain profitability and competitiveness, manufacturers prioritize building resilient supply chains. This mitigates the effects of these price fluctuations.

Strategic Recommendations for Brass Solenoid Valve Stakeholders

Stakeholders in the brass solenoid valve market must adopt strategic approaches. These strategies ensure sustained growth and resilience in a dynamic environment.

Investing in Research and Development

Manufacturers must prioritize research and development to remain competitive. This addresses evolving industrial demands. Companies should focus on several key areas:

- Energy Efficiency and Durability: Develop solutions that consume less energy and last longer.

- Advanced Technologies: Integrate IoT, AI, and real-time analytics for enhanced operational insights. This enables predictive maintenance and remote operation.

- Material and Design Improvements: Focus on better corrosion resistance, miniaturization, and customization.

- Extreme Operating Conditions: Design valves capable of operating under very high temperatures and pressures.

- Noise Reduction: Incorporate advanced features to reduce operational noise.

- Innovative Magnetic Technology: Utilize new magnetic technologies for energy savings.

- Regulatory Compliance: Address changing standards for data security and interoperability.

For example, Emerson Electric Co. develops low-power solenoid valves for water management. Schlumberger Limited focuses on high-performance valves for the petrochemical industry.

Diversifying Supply Chains

Diversifying supply chains mitigates risks and ensures operational continuity. Companies can accelerate local sourcing initiatives. They can also leverage strategic partnerships with domestic foundries and contract manufacturers. Exploring tariff engineering tactics helps manage costs. Nearshoring and vertical integration strengthen control over production. Material substitution offers flexibility. Pursuing targeted acquisitions can bolster capabilities in specialized materials. This expands product portfolios and secures access to critical raw materials. Cultivating supply chain agility through regional diversification and supplier consolidation is also effective. Investing in supply chain digitalization and resilience is key. This involves adopting advanced analytics, real-time tracking, and diversified sourcing strategies. These actions mitigate disruptions, reduce lead times, and ensure reliable delivery and cost control.

Prioritizing Sustainability and Green Manufacturing

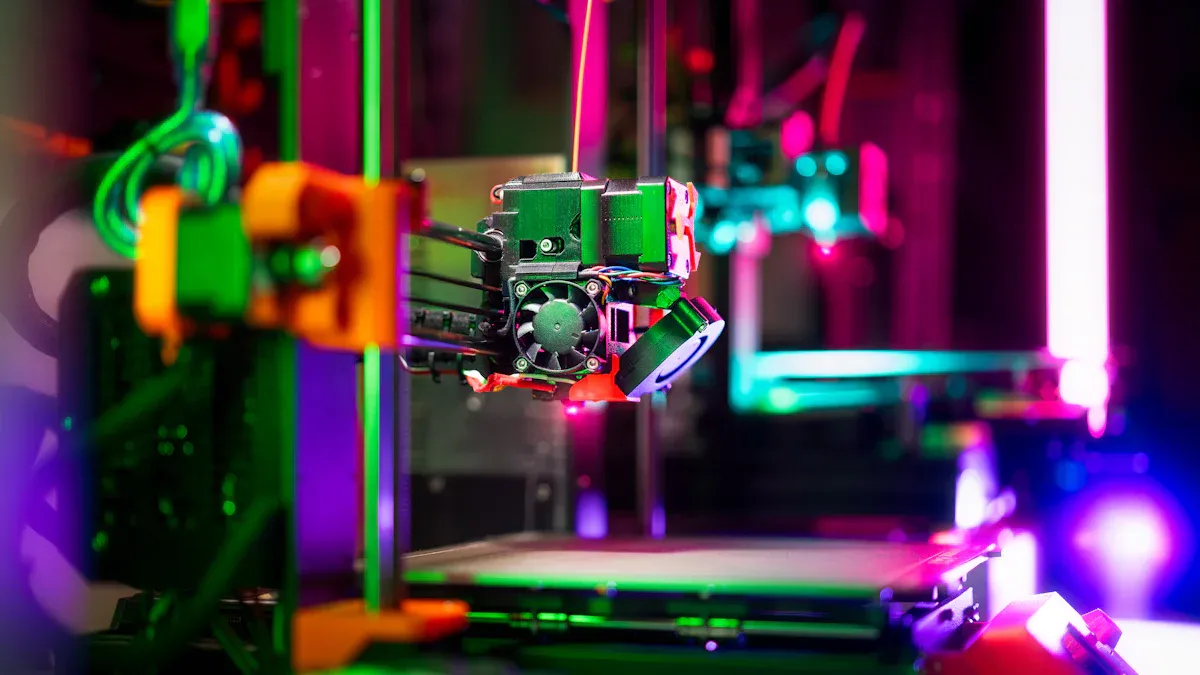

Prioritizing sustainability and green manufacturing is essential for long-term success. Manufacturers can adopt sustainable material practices. This includes exploring biodegradable polymers like polylactic acid (PLA) for non-critical components. Using recycled metals, especially aluminum and steel, for valve bodies reduces demand for virgin resources. Bio-based composites can be used for valve housings. Other sustainable practices include utilizing recycled brass and stainless steel. Replacing petroleum-based plastics with recyclable alternatives is important. Employing non-toxic coatings and sealants enhances durability. Energy-efficient manufacturing processes are also vital. Implementing precision casting minimizes waste. Integrating renewable energy sources like solar power reduces environmental impact. Additive manufacturing (3D printing) further reduces waste. Designing long-lasting components with materials like stainless steel extends product lifespan. Developing low-power solenoid coils improves operational energy efficiency. Sustainable packaging, using biodegradable or minimalist designs, also contributes to green goals.

Regional Outlook for the Brass Solenoid Valve Market

Growth Prospects in North America

North America’s brass solenoid valve market projects a strong Compound Annual Growth Rate (CAGR) of 5.8% between 2024 and 2030. This growth primarily stems from increasing automation, infrastructure upgrades, and rising demand from sustainable and smart building projects. The region’s robust industrial base and infrastructure investments support market adoption. Companies integrate AI and IoT, developing smart solenoid valves with real-time monitoring and predictive maintenance capabilities. Sustainability efforts favor recyclable and non-toxic brass for green plumbing and eco-friendly HVAC installations. Industries like pharmaceuticals demand high precision, requiring accurate and contaminant-free valve solutions. The market also shifts towards eco-friendly and energy-optimized systems, replacing manual valves. Modular and customizable valve systems, offering flexibility with interchangeable coils, are gaining traction. Key investment areas include industrial manufacturing, municipal water treatment, renewable energy, and commercial HVAC systems. Increasing construction activities, alongside booming pharmaceutical and food processing sectors, create demand for specialized valve solutions. Advancements in renewable energy and electric vehicle manufacturing also generate demand for compact and durable valves.

European Market Dynamics

The European market for solenoid valves demonstrates steady growth. Stringent environmental regulations and a strong focus on energy efficiency drive this trend. European industries increasingly adopt automation in manufacturing and process control, boosting demand for reliable fluid management solutions. The region’s commitment to sustainable practices also encourages the use of advanced valve technologies in HVAC systems and water management. Innovation in valve design, emphasizing durability and reduced power consumption, remains a key trend.

Asia-Pacific’s Dominance and Potential

Asia-Pacific is poised for the highest growth rate in the brass solenoid valve market. This growth stems from increased investments in water treatment plants and a regional focus on ensuring clean water availability. Rapid industrialization and urbanization across emerging economies also contribute significantly. The region experiences increasing demand from sectors such as manufacturing, water treatment, HVAC, and automation. Technological advancements in valve design lead to improved durability and energy efficiency. Stringent government regulations promote automation and process control systems. Growing infrastructure projects and the need for reliable fluid control systems further fuel market expansion. A rising focus on sustainable and eco-friendly solutions encourages efficient valve adoption. The expansion of automotive and electronics industries also increases demand for precise fluid control components.

The brass solenoid valve market faces dynamic evolution. It integrates advanced technology and sustainable practices. Stakeholders must adapt to innovation and market shifts. This allows them to capitalize on future opportunities within the brass solenoid valve sector. The market’s trajectory points towards smarter, more efficient, and environmentally conscious brass solenoid valve solutions.

FAQ

What are the primary advantages of using brass solenoid valves?

Brass solenoid valves offer excellent corrosion resistance and durability. They provide reliable fluid control in various environments. Their robust construction ensures a long service life. This makes them suitable for many industrial and commercial applications.

How do smart features benefit modern brass solenoid valves?

Smart features, like IoT integration, enable remote monitoring and control. They provide real-time data and predictive maintenance capabilities. This enhances operational efficiency and reduces downtime. Smart valves optimize performance and lower maintenance costs.

In which industries do brass solenoid valves see significant growth?

Brass solenoid valves experience significant growth in industrial automation, HVAC systems, and infrastructure projects. They also expand into smart homes, renewable energy, and medical sectors. These diverse applications drive market demand.

Why is sustainability a growing focus in brass solenoid valve manufacturing?

Sustainability focuses on reducing environmental impact. Manufacturers use recycled materials and energy-efficient processes. They design valves for longer lifespans and lower power consumption. This commitment supports green manufacturing practices and meets evolving market demands.