Solenoid valve fault repair demands a systematic approach. Technicians must begin by diagnosing the specific symptom of a solenoid valve, then identify the root cause of the malfunction. Following this, they perform the appropriate repair and thoroughly test the valve for proper function, ensuring reliable operation. An Introduction to solenoid valve types is invaluable for this diagnostic process. Many industrial applications utilize a high-precision solenoid valve. Understanding what are the characteristics of high-precision solenoid valves? is crucial for effective maintenance. Knowing in which fields are solenoid valves mainly applied? helps anticipate common issues.

Key Takeaways

- Understand how your solenoid valve works and its parts before you start any repair.

- Always prepare for repair by gathering the right tools and following safety rules like turning off power and releasing pressure.

- Diagnose common problems like the valve not opening, leaking, making strange noises, or getting too hot to find the right fix.

- Follow step-by-step solutions to clean clogs, replace bad coils, fix leaks, or solve electrical issues.

- Decide if you should repair or replace the valve by looking at the cost, damage, and how old the valve is.

Understanding Your Solenoid Valve

How a Solenoid Valve Operates

A solenoid valve functions by combining an electromagnet (solenoid) and a valve body. The solenoid contains a movable ferrous rod, known as a plunger or core, positioned within a tube that extends through the center of the electromagnetic coil. When a controller energizes the solenoid, the core moves to its equilibrium position within the magnetic field. This movement of the core directly changes the valve’s operating status, either opening or closing it, which then controls fluid flow through an orifice. The core is enclosed in a sealed tube, ensuring a leak-tight assembly. When de-energized, a spring returns the plunger or armature to its original position. Direct-acting solenoid valves have the seat seal attached to the solenoid core, opening when energized and closing when de-energized.

Key Components of a Solenoid Valve

A typical solenoid valve consists of several essential components, each with a specific function. The valve body serves as the main housing for internal parts like the orifice, plunger, spring, and seals. It is usually made from durable materials such as brass, stainless steel, or plastic, providing the pathway for media flow. The inlet port connects to the upstream system where media enters, while the outlet port connects to the downstream system where media exits. An orifice, a small opening inside the valve body, connects these ports and controls the flow. The solenoid coil, the valve’s core, generates a magnetic field when energized. This field actuates the plunger or armature, which moves to control media flow. A spring returns the plunger to its default position when the solenoid is de-energized. The armature tube houses the plunger and spring, guiding the armature’s movement. Electric terminals or lead wires provide the electrical connection to power the coil. Diaphragms or seals, made from leak-proof materials, prevent leaks and directly control the media path at the orifice.

Essential Preparations for Solenoid Valve Repair

Effective solenoid valve repair begins with thorough preparation. Technicians must gather the correct tools and prioritize safety. Proper preparation ensures a smooth repair process and prevents potential hazards.

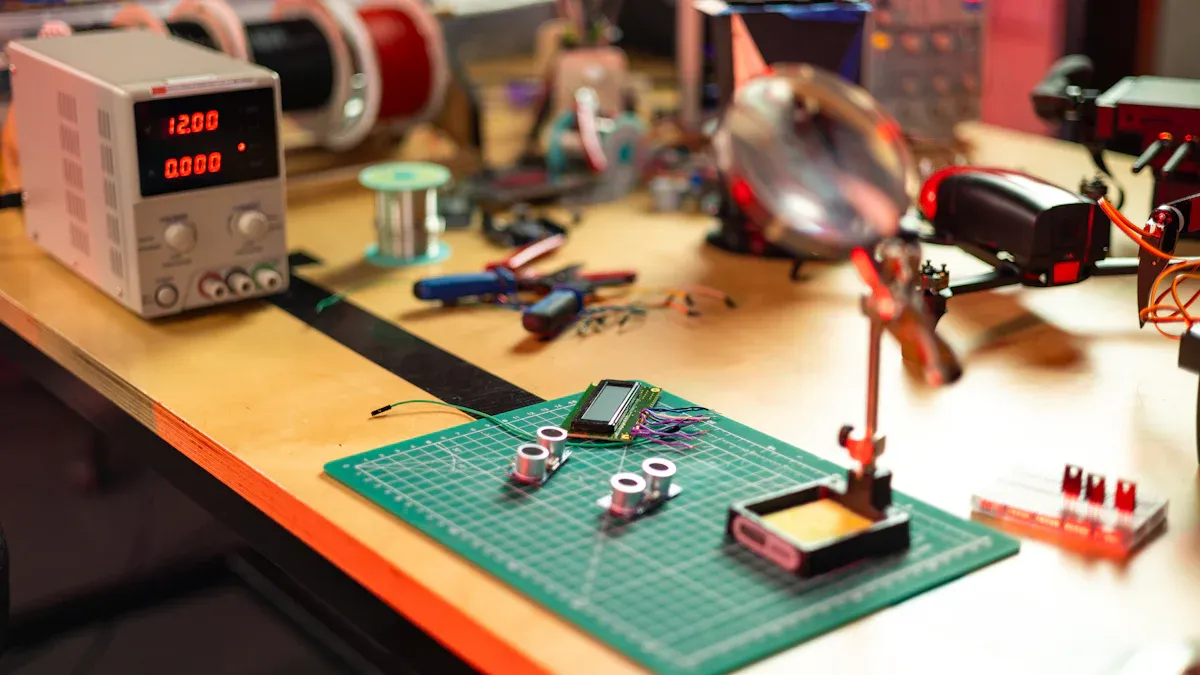

Tools Required for Solenoid Valve Repair

Successful repair tasks require specific tools. For common solenoid valve cleaning procedures, technicians need an adjustable wrench and an Allen screwdriver. Clean running water is essential for flushing components. A soft brush can assist with removing stubborn debris. If the repair involves replacing worn parts, a replacement diaphragm or a replacement coil may be necessary. These tools facilitate precise disassembly, cleaning, and reassembly of the valve components.

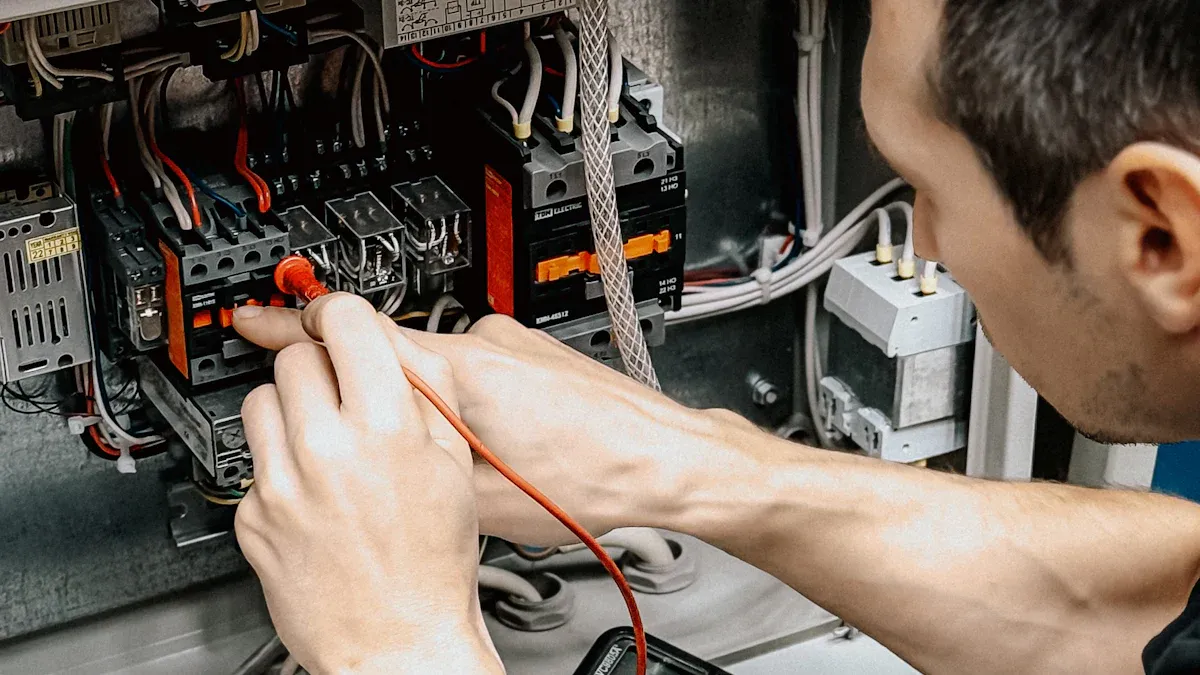

Safety Precautions for Solenoid Valve Work

Safety remains paramount when working with any solenoid valve. Technicians must always depressurize the system first. They implement lockout/tagout procedures to prevent injury from escaping air or fluid. Isolating the power supply is crucial; disconnect electrical power to prevent accidental activation during installation or maintenance. Always use personal protective equipment (PPE), including safety goggles and gloves.

⚠️ Safety Tip: Ensure proper ventilation and avoid hazardous environments. Use explosion-proof valves if the application requires them.

Technicians must follow manufacturer’s instructions for installation and wiring. They ensure the power supply matches the valve’s voltage. They also prevent overloading by operating within specified voltage, current, and pressure limits. This avoids overheating or damage. Regular maintenance and inspection help identify wear, leakage, or damage. Proper grounding prevents electrical shocks. Technicians verify fluid compatibility to prevent corrosion or clogging. They do not exceed the valve’s specified pressure and temperature ratings. Finally, training and education ensure employees understand proper installation, operation, maintenance, and safety procedures.

Diagnosing Common Solenoid Valve Failures

Understanding common failure modes helps technicians quickly identify and resolve issues. Prompt diagnosis minimizes downtime and prevents further system damage.

Solenoid Valve Not Opening or Closing

When a solenoid valve fails to open or close, several factors could be at play. Technicians must systematically check potential causes.

- Check for power to the coil: A common reason for a stuck valve is a loss of power to the coil or an interruption in power.

- Inspect for coil failure or burnout: Too much voltage can damage the coil, rendering the valve inoperable.

- Check for obstructions: If the valve will not close, inspect for foreign objects or debris caught in the stem.

- Verify adequate power to the circuit: If debris is not present, a power disruption could be the cause. Restore power and reset the solenoid if needed.

- Inspect valve alignment: If power is not the issue, check the valve’s alignment, especially if it was previously forced open. Inspect the seat and stem for damage.

Technicians also perform specific checks for electrical and valve components.

- Electrical Issues:

- Check the fuse in the irrigation controller and replace it if blown.

- Verify wiring connections. Ensure wires connect correctly to the common and station terminals. Confirm connections are tight.

- Valve Issues:

- Locate and open the flow control stem by turning it counter-clockwise.

- Check the flow arrow on the valve body to ensure it matches the water flow direction.

- Manual Switch Check:

- Locate the manual switch near the coil. Ensure it is in the ‘OFF’ position.

- Solenoid Coil Issues:

- Turn off power. Carefully unscrew the coil from the valve body for inspection.

For valves that do not open, technicians check for no power to the coil, incorrect voltage/frequency, a burnt coil, or differential pressure that is too high. Solutions include measuring voltage across the coil, ensuring the power supply matches specifications, and checking the pressure differential.

Solenoid Valve Leaking

Leakage from a solenoid valve indicates a compromise in its sealing integrity. Leaks can be external or internal.

- Contaminants in the Valve: Dirt, debris, or particulates can lodge in the valve or on the piston and diaphragm, preventing proper sealing.

- Worn or Damaged Seals: Seals or gaskets within the valve can wear out over time or suffer damage, leading to leaks.

- Improper Installation: Incorrect installation, such as misalignment or over-tightening, can cause leaks.

- Corrosion or Material Degradation: Exposure to corrosive fluids, chemicals, or environments, or selecting the wrong seal material, can degrade valve components.

- High Pressure or Overloading: Operating the valve beyond its rated pressure capacity can result in leaks.

- Solenoid Malfunction: A malfunctioning solenoid coil may prevent the valve from fully opening or closing, causing a leak.

- Temperature Issues: Extreme temperatures can cause valve materials to expand or contract, leading to leaks. Overheated coils can also contribute to this.

External leakage often results from degraded O-ring seals, which may be worn out or incorrectly installed. Wicking through diaphragm material also causes external leaks as pressurized fluid journeys through the diaphragm. Internal leakage, also known as seat leakage, typically occurs due to foreign materials in the process medium. Particles become trapped between the seat and sealing disc, causing gaps or indentations. Improper assembly of valve parts or misapplication of a valve, such as using a hard-seated valve when a soft seat is needed, also leads to internal leaks.

Solenoid Valve Making Unusual Noises

Unusual noises from a solenoid valve often signal underlying issues. Technicians identify the source by listening to the type of noise and performing targeted checks.

| Noise Type | Possible Cause | What to Check |

|---|---|---|

| Buzzing | Electrical issue | Coil voltage |

| Clicking | Mechanical problem | Plunger, spring |

| Humming | Loose coil or debris | Coil, valve interior |

Technicians perform several diagnostic procedures to pinpoint the source of unusual noises:

- Listen to the type of noise. Buzzing often indicates electrical issues. Clicking suggests mechanical problems.

- Check the coil for tightness.

- Use a multimeter to verify the voltage at the coil terminals against the valve’s rating.

- Remove and inspect the valve for internal dirt or debris.

- Look for worn or broken parts like the plunger or spring.

- Measure the system pressure with a gauge.

For loose fasteners, technicians perform visual inspections for loose or damaged fasteners. They listen for unusual noises indicating loose components. For resonance in the air supply system, they observe for excessive noise or signs of turbulence in pipes and valves. They also analyze the system design for potential resonance issues.

Solenoid Valve Overheating

A solenoid valve that overheats signals a significant operational issue, potentially leading to premature failure. Several factors contribute to this problem, and technicians must identify them to prevent further damage.

- Continuous Energization or High Cycling Use: Prolonged energization or frequent cycling generates internal heat within the coil. This heat rise, combined with ambient temperatures, can damage internal components over time.

- Electromagnetic Changes: Heat increases the coil’s electrical resistance. This change requires higher voltage for the valve to operate correctly. If the available voltage is insufficient, the valve may not actuate properly, which can contribute to further overheating.

- Moving Iron Core Issues: Problems with the moving iron core also cause overheating. Oil stains, impurities, or seal deformation can prevent the core from attracting normally or cause it to act too slowly. This decreases the coil’s inductance and impedance, leading to increased current and subsequent coil heating.

- Improper Selection: Choosing the wrong type of solenoid valve for a specific application, for instance, using a normally closed valve when the system requires a normally open one, can lead to continuous energization and overheating.

- Energy-Saving Module Failure: Some valves incorporate energy-saving modules designed to reduce power consumption and cool the coil. If this module fails, it can no longer perform its cooling function, resulting in coil heating.

- Overload Work: Operating the valve beyond its design specifications significantly contributes to overheating. This includes conditions such as higher working temperatures, elevated medium temperatures, excessive pressure, or poor power supply voltage. These factors force the valve to work harder, generating excess heat.

- Quality Problems: Inherent quality issues with the solenoid coil itself can directly result in overheating, even under normal operating conditions.

Technicians must address these underlying causes to resolve overheating issues and ensure the longevity of the solenoid valve.

Step-by-Step Solenoid Valve Repair Solutions

Effective repair of a solenoid valve requires a methodical approach. Technicians must follow specific steps to ensure proper function and prevent future issues. This section outlines common repair solutions for various malfunctions.

Cleaning a Clogged Solenoid Valve

A clogged solenoid valve often prevents proper operation. Cleaning it systematically restores functionality. Technicians begin by disconnecting the solenoid valve from its power supply. Next, they disconnect the inlet and outlet connections to remove the valve from the system. They carefully take the valve apart, remembering the location and orientation of each part.

Technicians clean each component with a suitable cleaning solution. They avoid harsh chemicals or abrasives. For plastic and rubber components, such as O-rings and diaphragms, a mild detergent works best. A general guideline suggests 10 ml of detergent per liter of water, unless the manufacturer specifies otherwise. For metal components like stainless steel or brass, isopropyl alcohol applied with a clean cloth or brush proves effective. Technicians use compressed air to remove dust and debris from orifices, such as the pilot valve orifice. They wear safety glasses and gloves during this process.

After cleaning, technicians completely rinse each part with clean water. This ensures no cleaning solution residue remains. They inspect individual parts for damage or wear. They replace any irreparable parts, including checking O-rings for replacement. Technicians carefully reassemble the valve, ensuring correct orientation and proper installation of all seals and O-rings. They reinstall the solenoid valve into the system, aligning inlet and outlet connections and tightening them appropriately. Finally, they connect the power supply back to the valve and test its functionality. Technicians monitor the valve for several days to ensure correct function and absence of leaks.

Replacing a Faulty Solenoid Valve Coil

A faulty solenoid valve coil often causes the valve to malfunction. Technicians identify a faulty coil by observing several common signs. A healthy coil typically produces a slight audible click when energized. The absence of this sound can indicate a broken coil, an open circuit, or an incorrect voltage supply. Technicians use a multimeter to check the voltage at the solenoid’s terminals when activated. This reveals if the coil receives the correct power. Voltage drops might point to faulty wiring, a failing power supply, or undersized cables. Measuring the coil’s resistance with an ohmmeter, after disconnecting it from the circuit, and comparing it to the manufacturer’s specifications can identify a damaged coil if a significant deviation exists. Discoloration on the solenoid coil suggests overheating or an electrical short circuit. While some AC solenoids naturally hum, an unusual buzzing sound can signal coil problems or issues with the AC voltage. Intermittent or temperature-dependent issues, such as the valve not opening or closing reliably, can link to marginal coil performance. Rapid opening and closing of the valve, known as chattering, often indicates incorrect voltage, which directly affects coil operation.

Replacing a faulty coil involves several key steps. Technicians first determine the coil dimensions. The replacement coil’s diameter and height should match the original, with a maximum tolerance of 15% of the armature diameter. They determine the voltage and electrical power. This involves identifying if the valve requires AC or DC voltage, such as 230V AC or 24V DC. They ensure the replacement coil’s electrical power (watts) is approximately equal to or higher than the defective coil’s value. For DC, power equals voltage multiplied by current. Technicians also determine the connector type. They identify the standardized electrical connector, such as DIN 43650-A or B, which are common square or rectangular types. They consider standards like the IP degree of protection, for example, IP65 for dust-tight and water jet protection, and ATEX compliance for potentially explosive atmospheres. For installation, technicians mount the coil on the solenoid valve. They ensure it is never connected to power when not mounted to prevent burnout. They follow the user manual for correct assembly and tighten the nut sufficiently to prevent rotation or vibration without overtightening. To change a solenoid coil, technicians carefully open the solenoid, detach the old coil, insert the new coil, and then reassemble the solenoid. They always refer to the valve manual for detailed installation instructions.

Repairing a Leaking Solenoid Valve Seal

Leaking seals compromise the integrity of a solenoid valve. Repairing them involves identifying the correct seal type and replacing it properly. Technicians commonly encounter several types of seals. These include Nitrile (Buna), EPR, FKM (Viton), Neoprene, Silicone, and Perfluoroelastomer (FFKM). Nitrile Butadiene Rubber (NBR) serves as a reliable seal material, particularly for low-pressure gas applications. It is a synthetic rubber composed of acrylonitrile (ACN) and butadiene. ACN contributes to resistance against media abrasion, while butadiene enhances flexibility and elasticity across different temperatures. NBR seals are versatile and find use in various industrial fluid applications, as well as in automotive and aerospace sectors for grease and mineral oils. PTFE (Polytetrafluoroethylene) is a seal material specifically suited for severe chemical resistance applications. It is highly insoluble, possesses high temperature resistance, and is chemically inert. PTFE commonly serves for diaphragms and flange gaskets in demanding chemical environments.

Technicians must select the appropriate replacement seal material based on the fluid, temperature, and pressure of the application. They carefully disassemble the valve, noting the position of all seals and O-rings. They remove the old, damaged seals. They clean the sealing surfaces thoroughly to ensure no debris interferes with the new seal. Technicians then install the new seals, ensuring correct orientation and proper seating. They reassemble the valve, tightening fasteners to the manufacturer’s specifications. Over-tightening can damage new seals. After reassembly, technicians test the valve for leaks under operating conditions.

Addressing Electrical Issues in a Solenoid Valve

Electrical problems often cause solenoid valve malfunctions. These issues can sometimes mimic mechanical failures. Technicians must understand these electrical nuances for effective troubleshooting. Insulation breakdown is a common problem. Heat, oil mist, and vibration can degrade wire insulation. This degradation leads to short circuits or grounding issues. These issues can appear as mechanical problems. Loose terminal connections also cause intermittent faults. These connections might seem fine during inspection. However, they lose contact due to vibration or thermal expansion. Underpowered coils present another challenge. A low-current signal can cause the coil to buzz. The valve will not move properly. People often mistake this for a sticking valve. Erratic valve timing can disrupt control loops. Valves open and close off-schedule. This indicates an electrical lag, not a process issue. Heat buildup is also critical. An overheated solenoid may stop actuating. It waits for cool-down, even if mechanically sound. Coil resistance can drift as windings degrade. This causes inconsistent actuation. Such issues are hard to replicate during testing. Voltage drops under load are common in older systems or long cable runs. This delivers insufficient power to the coil. It leads to a failure to maintain hold without alarms.

Troubleshooting electrical issues requires specific steps. The controller might display ‘short’ or ‘open’ messages. This provides an immediate clue. Some zones of a sprinkler system may function correctly. Other zones do not. This pattern suggests an electrical problem in the non-functioning zones. Technicians utilize various types of electrical diagnostic equipment. This equipment helps pinpoint the problem quickly. They check for continuity and resistance in the coil. They also verify voltage at the terminals.

Fixing Pressure Imbalances Affecting Solenoid Valve

Pressure imbalances significantly affect solenoid valve function. Internal forces caused by pressurized media can hinder operation. Pressure-balanced solenoid valves are specifically engineered to neutralize these forces. This design optimizes the shifting forces from the coil and return spring. These forces can then focus on sealing the poppet effectively. This meets stringent leakage specifications. Without such balancing, internal forces from pressure negatively impact valve operation and sealing.

Pressure solenoid valves manage fluid or gas flow based on pressure conditions. They operate by opening or closing in response to pressure changes within a system. They regulate pressure by allowing or blocking flow. For instance, a pressure relief valve is typically normally closed. It opens when system pressure exceeds a set point. This releases excess pressure. Technicians must ensure the valve’s pressure rating matches the system’s operating pressure. They also check for blockages or restrictions in the flow path. These can create localized pressure differences. They verify the proper functioning of pressure regulators in the system. This ensures stable inlet pressure to the valve.

Deciding to Repair or Replace Your Solenoid Valve

When a solenoid valve malfunctions, technicians face a critical decision: repair the existing unit or replace it with a new one. This choice involves evaluating several factors, including cost, complexity, and the valve’s overall condition. Making the right decision saves time and resources while ensuring system reliability.

Cost-Benefit Analysis for Solenoid Valve Repair

Technicians perform a cost-benefit analysis to determine the most economical path. This analysis weighs the expense and effort of repair against the cost of a new unit.

| Factor | Consider Repair if… | Consider Replacement if… |

|---|---|---|

| Valve Body | Intact, no cracks, minimal corrosion | Cracked, heavily corroded, irreparable physical damage |

| Replacement Parts | Affordable, readily available, specific to your valve (e.g., rebuild kits) | Unavailable, expensive, or no longer manufactured for your model |

| Your Skill & Tools | You have the necessary tools and feel confident in performing the repair reliably | The repair seems beyond your skill level or requires specialized tools |

| Application Risk | Non-critical, low-risk if failure recurs (e.g., a simple irrigation zone) | Involves hazardous fluids, high pressures, or critical safety functions |

| Cost Analysis | Repair cost significantly less than a new, warrantied unit | Repair cost approaches or exceeds the cost of a new valve |

| Valve Age | Relatively new or mid-lifespan | Very old, nearing end of expected lifespan, or prone to recurring issues |

Factors like the valve’s design and durability, along with the overall application, influence this decision. Simple, inexpensive valves often make replacement the most cost-effective choice. However, high-end or custom-designed valves, while costly to replace, may not have their original function replicated by field maintenance. This makes replacement the best recommendation despite the higher initial cost. Maintenance typically involves replacing rubber parts and springs. Technicians should also replace any worn or damaged components. The valve’s connection type and location can also influence the decision. If removal is difficult or dangerous, rebuilding components in place might be preferable, provided the valve seat is not damaged. When cost is the primary criterion, replacement is often the best choice for a solenoid valve. The labor cost for disassembly, repair, reassembly, installation, and performance checks can frequently outweigh the cost of simply installing a new valve.

When to Replace a Solenoid Valve

Replacement is often more advisable than repair under specific conditions. Technicians consider these situations carefully.

- Extensive Damage or Corrosion: If the valve body is cracked, heavily corroded, or shows irreparable physical damage, replacement is often necessary.

- Aging Valve / End of Lifespan: For very old valves that have seen extensive service, replacement can prevent recurring issues.

- Safety Concerns: In applications involving hazardous fluids, high pressures, or critical safety functions, replacement is almost always recommended. This applies unless a manufacturer-defined repair is meticulously executed.

- Cost of Repair Outweighs Replacement: If the cost of parts, labor, and your time approaches or exceeds the cost of a new, warrantied valve, replacement is more economical.

- Complexity of the Repair for DIYers: If the repair is beyond your skill level or requires specialized tools, replacement can save frustration and potential damage.

- Lack of Specific Parts: If replacement parts are unavailable, expensive, or no longer manufactured for your specific valve model, replacement becomes the only viable option.

Post-Repair Testing and Solenoid Valve Maintenance

After repairing a solenoid valve, technicians must thoroughly test its function. This ensures the repair was successful and the valve operates reliably. Proactive maintenance also prevents future failures, extending the valve’s lifespan.

Verifying Proper Solenoid Valve Function

Technicians perform several tests to verify proper solenoid valve function. These tests confirm the electrical and mechanical integrity of the repaired unit.

-

- Set a multimeter to measure resistance (Ω).

- Connect multimeter probes to the solenoid’s testable terminals. Consult the manual if unsure.

- Note the readings. An ‘OL’ (infinite resistance) indicates an incomplete circuit, requiring solenoid replacement. Compare readings to the manufacturer’s expected range.

-

Voltage Testing:

- Check the solenoid manual for AC or DC voltage specifications. Set the multimeter accordingly.

- Connect multimeter probes to the solenoid terminals.

- Note the results. If the reading matches the rated voltage, the coil is operating normally. Otherwise, the coil is faulty.

- Turn off power and disconnect probes.

-

Functional Testing:

- Confirm the valve’s voltage and current ratings from the manufacturer datasheet or nameplate.

- Determine the valve’s port configuration (normally closed or normally open).

- Set up the instrument as per the typical test configuration.

- Connect an air supply to a pneumatic filter regulator to filter and regulate the air.

- Apply specified air pressure to the valve’s inlet port. Connect the power supply to the valve terminals.

- Switch on the power supply. Monitor a test gauge pressure to confirm the valve is energized. Pressure should increase.

- Switch off the power supply. Confirm the valve is de-energized by checking the test gauge pressure again. Pressure should decrease.

- Record all results in a check sheet. If pressure does not decrease when power is off, the valve may be stuck open due to a coil malfunction or debris, requiring inspection.

Tips for Preventing Future Solenoid Valve Failures

Preventative maintenance significantly reduces the likelihood of future valve failures. Technicians implement several key practices.

- Ensure the power supply matches coil specifications before installation. The coil needs proper ventilation to expel heat effectively.

- Mount a new coil securely on the valve before powering it.

- Check for and dry any moisture within the coil. Replace armatures if damaged or bent.

- Ensure media compatibility with the valve to prevent malfunctions.

- Relocate valves to cooler areas or increase airflow around them and their coils as needed.

- Inspect seals, O-rings, and membranes for damage or wear. Replace them if necessary.

- Clean thoroughly for dirt particles and solid contaminants in pipe connections and valve openings before reassembling.

- Ascertain the valve type (semi-direct, direct, or pilot-operated) before installation. Semi-direct valves require differential pressure with certain media.

- Ensure flow and pressure specifications are compatible with manufacturer limitations.

- Inspect for and eliminate any back pressure caused by clogged filters in the line piping system prior to installation.

- Apply the correct voltage and frequency to the coil as specified to prevent failure.

- Incorporate electrical surge protection (Circuit breakers/MCBs) to guard against electrical spikes.

- Ensure the coil possesses the appropriate IP (Ingress Protection) rating for the application and installation location, especially in moist environments.

- Install an upstream filter to prevent debris, sediment, or particle contamination from limiting armature motion and causing overheating.

- Install the valve with the coil and armature aligned vertically to decrease the probability of sediment dropping into the tube.

- Replace malfunctioning, fried, or damaged coils promptly to avert system breakdown.

- Regularly inspect valve response time and calibration to ensure optimal performance. Troubleshoot potential issues.

- Connect the valve in the correct direction, with the inlet port upstream and the outlet port downstream, following the arrow on the valve body.

- Ensure the supply voltage matches the coil’s specifications (+/- 10%).

- On pilot-operated or assisted-lift valves, ensure no vacuum exists on the downstream side.

Predictive maintenance and smart monitoring also offer significant benefits.

| Monitoring Component | Function | Prevents Problems Like… |

|---|---|---|

| Flow & Pressure Sensors | Detect abnormal pressure drops or inconsistent flow | Clogging, internal wear, or stuck valves |

| Coil Temperature Monitors | Watch for heat buildup during valve operation | Coil burnout, electrical insulation damage |

| Cycle Counters | Track number of actuations in high-duty environments | Predicts fatigue or spring/seal failure |

| Electrical Current Sensors | Monitor abnormal voltage draw during actuation | Short circuits, damaged windings |

Regular maintenance and prompt troubleshooting are crucial for extending the lifespan of your solenoid valve. Proactive maintenance, often performed during machinery servicing, extends product life and optimizes performance. This approach involves identifying wear and tear, replacing affected components, and cleaning to prevent material build-up. Knowing when to repair or replace your solenoid valve saves both time and resources.

FAQ

How often should technicians perform maintenance on a solenoid valve?

Maintenance frequency depends on the application and operating conditions. For critical systems or harsh environments, technicians recommend more frequent checks. Generally, annual inspections are a good starting point. They look for wear, leaks, and proper function.

Why does a solenoid valve sometimes overheat?

Continuous energization or high cycling causes overheating. Electromagnetic changes increase the coil’s electrical resistance. Issues with the moving iron core also contribute. Improper valve selection or a failed energy-saving module can also lead to excessive heat.

Can technicians use any coil as a replacement for a solenoid valve?

No, technicians must use a coil that matches the valve’s specifications. The replacement coil needs the correct voltage, electrical power, and connector type. Using an incompatible coil causes damage or improper operation. Always refer to the manufacturer’s manual.

What is the most common reason for a solenoid valve leak?

Worn or damaged seals and O-rings are the most common culprits for leaks. Contaminants lodged in the valve also prevent proper sealing. Technicians should inspect these components regularly. They replace them as needed to maintain seal integrity.

When should technicians choose to replace a solenoid valve instead of repairing it?

Technicians should replace a valve if it has extensive damage, is very old, or poses safety risks. Replacement is also more economical if repair costs exceed a new valve’s price. Unavailable parts also necessitate replacement.