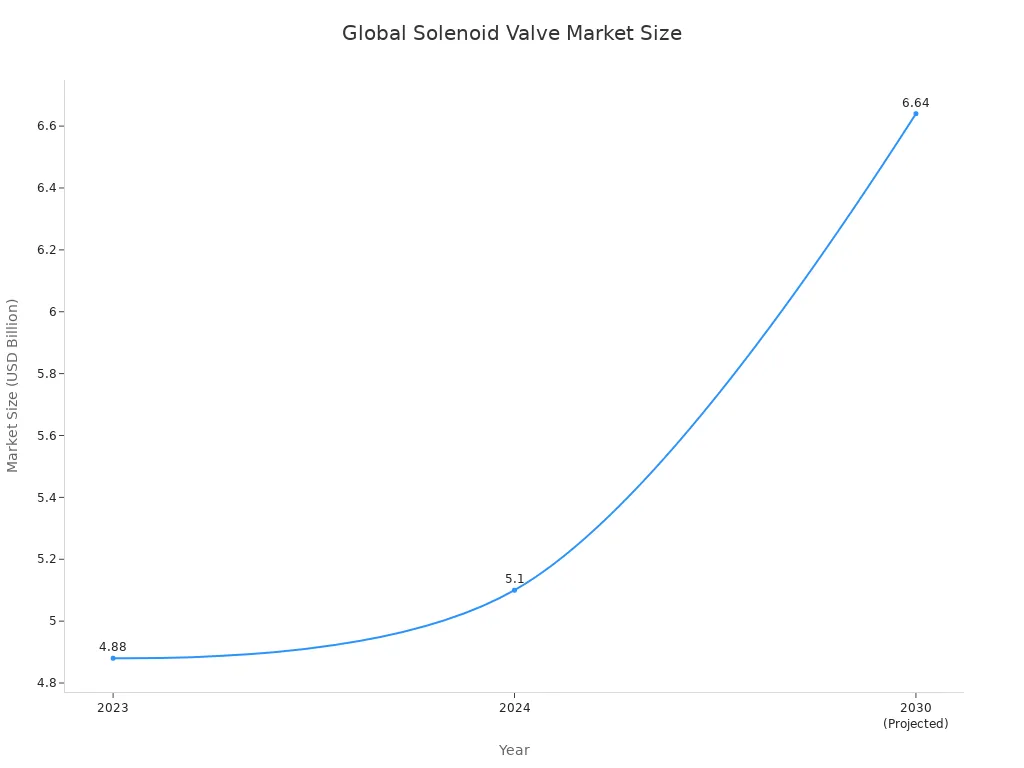

While pinpointing a single ‘most reliable’ Chinese brand of brass solenoid valves is challenging, brands like Yuyao No.4 Instrument Factory (Y4), Ningbo Kailing, and Zhejiang Sanhua consistently perform strongly. They offer reliable Brass Solenoid Valve products for diverse industrial and commercial applications. The global solenoid valve market shows significant growth, as seen below:

| Source | Year | Market Size (USD Billion) |

|---|---|---|

| Data Bridge Market Research | 2024 | 4.99 |

| Data Bridge Market Research | 2032 (Projected) | 5.98 |

This market size emphasizes the need for a trustworthy custom solenoid valve manufacturer. Ningbo Custom Solenoid Valve Manufacturer companies, for instance, contribute high-quality pneumatic components, including Stainless Steel Solenoid Valve options. This post identifies leading Chinese manufacturers and outlines key quality assessment factors.

Key Takeaways

- Top Chinese brands like Yuyao No.4 Instrument Factory (Y4), Ningbo Kailing, and Zhejiang Sanhua offer reliable brass solenoid valves.

- Good brass solenoid valves have high-quality materials, precise manufacturing, and strong quality control with certifications.

- Always check product specifications, supplier reputation, and warranty before buying valves.

- Avoid buying the cheapest valve; it can cost more in the long run due to frequent repairs and downtime.

- Proper installation, regular cleaning, and following manufacturer instructions help valves last longer.

Key Reliability Factors for Brass Solenoid Valves

Material Quality and Construction

The foundation of a reliable Brass Solenoid Valve lies in its material quality. Manufacturers select specific brass alloys for their valve bodies. Brass, an alloy of copper and zinc, is commonly used. Copper typically constitutes 55-90% of the alloy. This enhances electrical and thermal conductivity, as well as corrosion resistance. Zinc, present in quantities of 5-45%, improves the material’s ductility. This makes it easier to machine for intricate flow patterns in valves and extends durability. Other elements such as lead, nickel, manganese, and tin can be added in small amounts. These additions further improve physical properties for specific environmental conditions. High-quality construction ensures the valve body withstands operational pressures and temperatures without leaks or structural failure.

Manufacturing Precision and Tolerances

Manufacturing precision directly impacts a solenoid valve’s performance and lifespan. Tight tolerances ensure that all internal components fit together perfectly. This prevents issues like internal leakage, premature wear, or sticking of the plunger. Precise machining of valve seats and orifices guarantees accurate flow control and consistent operation. Manufacturers use advanced machinery and strict measurement protocols to achieve these high levels of accuracy. This attention to detail minimizes friction and maximizes the efficiency of the valve’s opening and closing cycles.

Quality Control and Certifications

Robust quality control procedures and adherence to international standards are non-negotiable for reliable valves. Manufacturers implement rigorous testing at various production stages. This includes material inspection, in-process checks, and final product testing. Certifications provide independent verification of a product’s quality and safety. Key international certifications include:

- CE (Conformité Européenne): This mandatory certification ensures products sold in the European Economic Area meet EU health, safety, and environmental protection standards.

- RoHS (Restriction of Hazardous Substances): This certification indicates compliance with EU directives restricting hazardous materials in electrical and electronic items.

- UL (Underwriter Laboratories): This globally recognized certification applies to product safety, especially for electrical devices.

- CSA Certification: This signifies that solenoid valves meet the specifications of the Canadian Standards Association.

- IECEx Certification: This international certification indicates suitability for various hazardous applications globally.

- IP Ratings: These define the level of protection a solenoid valve offers against the intrusion of solids and liquids. These certifications assure users of the product’s safety, environmental compliance, and performance standards.

Durability Under Operating Conditions

Reliable solenoid valves must withstand harsh operational environments. Manufacturers design these valves to endure specific pressure and temperature ranges. For industrial applications, valves often face high pressures. They also handle a wide spectrum of process temperatures.

- Typical Industrial Ranges:

- Maximum Pressure: 1450 psi (100 bar)

- Process Temperature Range: -23°C to 182°C (-10°F to 360°F)

Some valves offer slightly different specifications.

- Alternative Specifications:

- Pressure Resistance: 0.5-1.6 Mpa

- Temperature Range: -5°C to 80°C (120°C optional)

The valve’s construction and material choices directly impact its ability to perform under these conditions. A durable valve resists corrosion, wear, and fatigue from continuous operation. It maintains its integrity even when exposed to aggressive media or extreme thermal cycles. This ensures consistent performance and prevents unexpected failures.

Longevity and Cycle Life

The lifespan of a solenoid valve is often measured in cycles. A cycle represents one complete opening and closing operation. High-quality industrial pneumatic valves commonly achieve life ratings in the tens of millions of cycles. The working environment significantly influences a valve’s actual lifespan.

| Working Environment | Life Expectancy |

|---|---|

| Great Working Environment | Tens of millions of cycles, more than 10 years |

| Normal Working Environment | 1~5 million cycles, 3~5 years |

| Bad Working Environment | Less than 1 million times, 1~2 years |

Specific valve series also show varying cycle life expectations.

| Valve Type / Condition | Expected Lifespan (Cycles) |

|---|---|

| General Brass Valves (dry air/gas) | Up to 20 million |

| Brass 8210Q Series | 5 million |

| Brass 8262Q Series | 20 million |

| Industrial Solenoid Valve (continuous operation) | 1 million to 10 million |

| Universal Solenoid Valve | 1 million to 10 million |

| Normal Working Environments | 1 million to 5 million |

| Excellent Conditions | Tens of millions |

A general brass valve handling dry air or gas can achieve up to 20 million cycles. Valves operating under excellent conditions can even reach tens of millions of cycles. Manufacturers design these valves for extended service, minimizing the need for frequent replacements. This reduces operational costs and downtime for businesses.

Top Chinese Brands for Reliable Brass Solenoid Valves

Yuyao No.4 Instrument Factory (Y4)

Yuyao No.4 Instrument Factory, often known as Y4, has established a strong reputation in the Chinese solenoid valve market. The company specializes in manufacturing a wide range of solenoid valves, including those made from brass. Y4 focuses on producing reliable and durable products suitable for various industrial applications. Their commitment to quality control and consistent performance makes them a preferred choice for many businesses. Customers often praise Y4 for its robust construction and long-lasting operational life. The factory continually invests in research and development to improve its product lines and meet evolving industry standards.

Ningbo Kailing Pneumatic Co., Ltd.

Ningbo Kailing Pneumatic Co., Ltd. stands out as a prominent manufacturer of pneumatic components, including high-quality Brass Solenoid Valve products. The company has built a reputation for its comprehensive product range and commitment to customer satisfaction. Ningbo Kailing’s brass solenoid valves find common use across diverse industrial sectors. These include machinery, metallurgy, food processing, textile manufacturing, and waste treatment. Their valves effectively handle various media, such as air, water, oil, and gas, demonstrating their versatility and robust design. Ningbo Kailing emphasizes precision engineering and rigorous testing to ensure its products meet demanding performance requirements.

Zhejiang Sanhua Co., Ltd.

Zhejiang Sanhua Co., Ltd. is a globally recognized leader in refrigeration and air conditioning components, and they also produce reliable brass solenoid valves. Sanhua distinguishes itself through significant investment in technological innovation and patented designs. For example, Sanhua developed a solenoid valve control system (Patent WO2017015037A1). This system uses a controller, environmental sensor, and database to optimize solenoid coil power consumption. It proactively reduces power consumption under normal conditions and increases it as needed without continuous monitoring. Another innovation is their solenoid valve design (Patent WO2017154797A1). This design features a removed portion on the inner side of the main valve body’s end face. It optimizes the contact area ratio between outer and inner diameters to reduce sticking. The end surfaces are shaped for easier separation, including diagonal cuts and annular non-contact portions, which minimize contact with the valve holder. These innovations highlight Sanhua’s dedication to enhancing valve efficiency and preventing common operational issues.

Ningbo Huarui Automation Equipment Co., Ltd.

Ningbo Huarui Automation Equipment Co., Ltd. has carved a niche in the automation industry. They specialize in manufacturing pneumatic components, including a diverse range of solenoid valves. The company emphasizes precision engineering and robust construction. This ensures their products perform reliably in demanding industrial environments. Huarui’s commitment to quality control is evident throughout their production process. They conduct rigorous testing on each valve before it reaches the market. This dedication helps them maintain a strong reputation for durability and consistent performance. Customers often choose Huarui for their wide selection of valves and their ability to meet specific application requirements.

Zhejiang Xinhong Valve&fitting Co., Ltd.

Zhejiang Xinhong Valve&fitting Co., Ltd. is a well-regarded manufacturer focusing on valves and fittings. Their product portfolio includes various types of solenoid valves, often featuring brass construction. Xinhong has extensive experience in the valve industry. This experience allows them to produce components known for their reliability and long service life. The company employs advanced manufacturing techniques and carefully selects raw materials. This ensures their valves meet high performance standards. Xinhong serves both domestic and international markets. They consistently deliver products that adhere to recognized quality certifications. Their focus on customer satisfaction and product integrity makes them a dependable supplier.

Other Notable Brass Solenoid Valve Manufacturers

Several other Chinese manufacturers also produce reliable brass solenoid valves. These companies contribute significantly to the market with their specialized offerings and commitment to quality.

- SENYA (Ningbo SENYA Pneumatic Technology Co., Ltd.): SENYA is an integrated organization that manufactures and exports pneumatic components. They focus on producing valves, cylinders, and other pneumatic-related products. SENYA has a high brand reputation and rich industrial application experience. They offer reliable solutions for various pneumatic systems.

- Wenzhou Sanlian Valve Co., Ltd.: This company specializes in a broad range of industrial valves. They often include brass solenoid valves in their product lines. Sanlian is known for its strong research and development capabilities. They produce valves suitable for diverse applications, from water treatment to chemical processing.

- Shanghai Yuxing Valve Co., Ltd.: Yuxing Valve has a long history in valve manufacturing. They provide a variety of valves, including solenoid valves made from brass. The company focuses on product innovation and strict quality management. This ensures their valves meet international standards and customer expectations.

- Festo (China) Ltd. (though a German company, their significant manufacturing presence in China makes them a notable player): While not a purely Chinese brand, Festo’s large manufacturing facilities in China produce high-quality pneumatic components, including solenoid valves. They bring global standards of engineering and quality control to the Chinese market. This makes them a strong contender for reliable valve solutions.

These manufacturers collectively offer a robust selection of brass solenoid valves. They cater to a wide array of industrial and commercial needs. Each company brings its unique strengths in terms of specialization, innovation, and market reach.

Verifying Reliability of Chinese Brass Solenoid Valves

Checking Certifications and Standards Compliance

Buyers must confirm that Chinese manufacturers adhere to international certifications and standards. These certifications guarantee product quality, safety, and environmental compliance. For instance, UL Certification indicates compliance with North American safety standards. CE Marking is mandatory for products sold in the European Economic Area. It shows adherence to health, safety, and environmental protection standards. ATEX Certification is crucial for valves used in potentially explosive environments. CSA Certification applies to Canadian markets and some hazardous applications in the US. IECEx Certification makes valves acceptable for various hazardous applications worldwide.

Furthermore, NEMA Ratings and IP Ratings define protection levels against environmental elements like moisture and dust. Manufacturers also follow specific ISO standards. ISO 5599 provides guidelines for pneumatic fluid power components. IEC 61508 ensures functional safety in electrical and electronic systems. Safety Integrity Levels (SIL) measure the reliability of safety systems, ensuring valves meet critical safety needs.

Reviewing Product Specifications and Data Sheets

Thoroughly examining product specifications and data sheets is essential. These documents provide critical information about a valve’s performance capabilities. Key parameters include corrosion resistance and chemical compatibility. Valve materials must not react with service media. They also must not leach impurities. High-purity valves withstand media and environmental corrosion. Materials must also endure elevated process temperatures and pressures without deforming. This prevents sealing compromises.

Consider these parameters from a typical datasheet:

| Parameter | Valve 1 (Article No. 20293) | Valve 2 (Article No. 24902) |

|---|---|---|

| Type | 0330 | 0330 |

| Orifice Size | 3.00 mm (1/8 inch) | 3.00 mm (1/8 inch) |

| Pressure Range | 0.00 bar – 10.00 bar | 0.00 bar – 10.00 bar |

| Body Material | Brass | Brass |

| Connection Type | Inner thread – G1/4 | Inner thread – G1/4 |

| Voltage | 24.00 V | 230.00 V |

| Seal Material | FKM (Fluor rubber) | NBR (Nitrile rubber) |

| Operating Temperature | 0.00 °C – 90.00 °C | 0.00 °C – 80.00 °C |

These details help determine if a valve suits specific application requirements.

Assessing Supplier Reputation and Reviews

Evaluating a supplier’s reputation and customer reviews offers valuable insights into reliability. A strong reputation indicates consistent product quality and customer satisfaction. Look for suppliers with positive feedback regarding product performance, delivery times, and after-sales support. Online reviews, industry forums, and direct testimonials provide real-world experiences. Suppliers with a long history in the industry often demonstrate greater stability and commitment to quality. They typically have established processes for manufacturing and quality control. This assessment helps buyers choose a trustworthy partner.

Considering Warranty and After-Sales Support

A robust warranty and reliable after-sales support are crucial indicators of a manufacturer’s confidence in its products. A good warranty protects buyers from defects in materials and workmanship. For example, many suppliers offer a one-year warranty for their valves, including brass valves. This warranty covers defects under normal use from the purchase date. Some specialized products, like Rain Bird’s EFB-CP Brass Valves, even come with a three-year warranty. This longer period reflects the manufacturer’s assurance of durability. Beyond the initial purchase, effective after-sales support ensures long-term operational success. This support includes technical assistance, availability of spare parts, and troubleshooting services. Manufacturers who prioritize these services demonstrate a commitment to customer satisfaction and product longevity. Buyers should always inquire about these provisions before making a purchase.

Requesting Samples for Testing

Requesting samples for testing allows buyers to verify valve performance firsthand before committing to a large order. This practice helps confirm the quality and suitability of the valves for specific applications. Buyers can perform several key tests on samples.

- Resistance Testing: Set a multimeter to measure resistance (Ω symbol). Connect the multimeter probes to the solenoid’s terminals. Consult the manufacturer’s manual for the expected resistance range. An ‘OL’ reading indicates an incomplete circuit, which means the solenoid needs replacement.

- Voltage Testing: Check the solenoid manual for AC or DC voltage specifications. Set the multimeter to the appropriate voltage measurement (V~ for AC, V… for DC). Connect the multimeter probes to the solenoid terminals. If the reading matches the rated voltage, the solenoid operates normally. Otherwise, the coil is faulty. Always turn off the power supply and disconnect probes after testing.

- Functional Testing: Perform functional tests to ensure the solenoid valve operates correctly in its intended application. This involves observing its opening and closing cycles under simulated or actual operating conditions.

To prevent electric shock from high voltage generated by solenoid inductance when disconnecting power, use a switch in series or connect a reverse-biased diode across the solenoid. Failure to do so can lead to sparks and other hazards.

These tests provide objective data on a valve’s reliability and performance.

Avoiding Pitfalls When Purchasing Brass Solenoid Valves

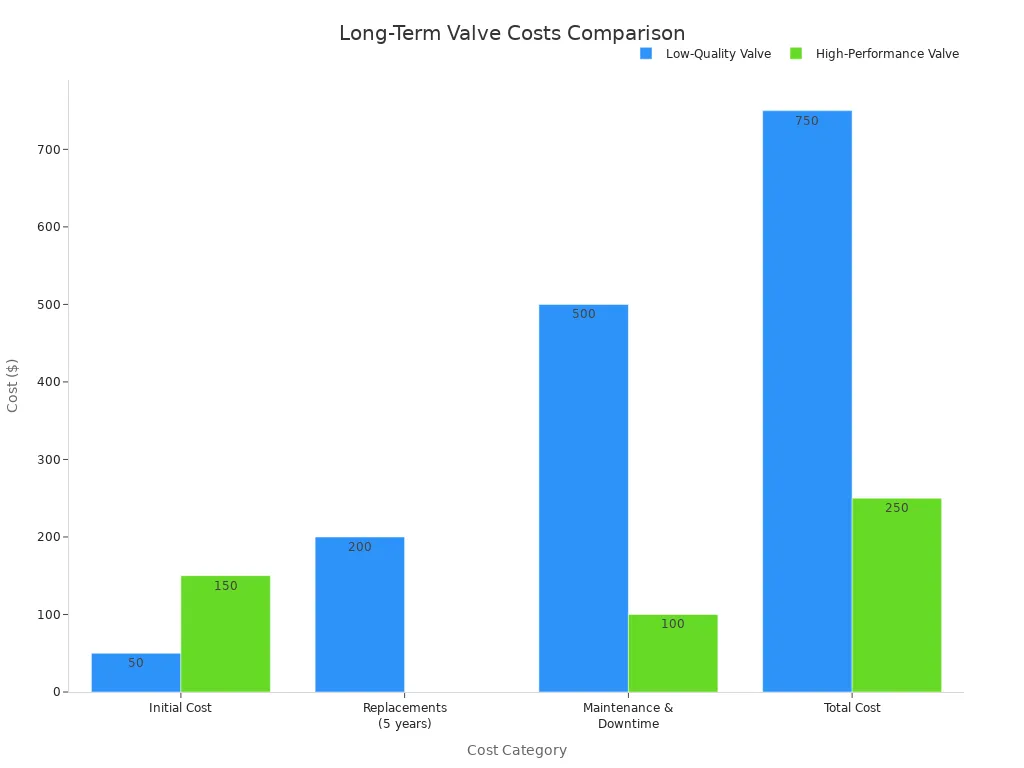

Prioritizing Lowest Price Over Quality

Many buyers often focus on the lowest initial price when purchasing a Brass Solenoid Valve. This approach can lead to significant long-term costs. Low-quality valves often result in frequent failures and operational disruptions. They also require more frequent servicing and replacement parts. Equipment failures can halt production, causing lost revenue. Malfunctions in critical systems due to poor-quality valves can also endanger workers and equipment. Consider the hidden costs:

- Frequent Failures: Inferior materials often result in breakdowns and operational disruptions.

- Increased Maintenance: Cheaper valves typically require more frequent servicing and replacement parts.

- Downtime Losses: Equipment failures can halt production, leading to lost revenue.

- Safety Risks: Malfunctions in critical systems due to poor-quality valves can endanger workers and equipment.

This table illustrates the cost difference:

| Category | Low-Quality Valve | High-Performance Valve |

|---|---|---|

| Initial Cost | $50 | $150 |

| Replacements (5 years) | $200 | $0 |

| Maintenance & Downtime | $500 | $100 |

| Total Cost | $750 | $250 |

Ignoring Application-Specific Requirements

Selecting a valve without considering its specific application can cause serious problems. For example, brass is prone to dezincification, where zinc leaches out, especially in harsh water. This compromises valve integrity and lifespan. Internal surfaces of brass valves can also corrode in applications with corrosive materials or high flow rates. This negatively impacts performance. Brass valves are unsuitable for extreme temperatures, such as cryogenic fluids or very high-temperature environments. These conditions require alternative materials like stainless steel. Exposure to cryogenic fluids can cause shrinkage of moving parts, leading to operational issues like clogging and ice formation.

Valves used in sensitive applications, like drinking water systems, must adhere to strict regulations (e.g., RoHS, REACH). Non-compliance can result in legal repercussions and restrict the valve’s market use.

Incorrect voltage ratings can stress the coil. Overtightening fittings can crack the valve body. Misaligned piping can cause flow restrictions or leaks. Failure to follow manufacturer guidelines can lead to system failure, increased energy consumption, and safety hazards.

Purchasing from Unverified Suppliers

Buying from unverified suppliers carries significant risks. These suppliers may offer products of inconsistent quality. They often lack proper quality control processes. This can lead to receiving counterfeit or substandard valves. Unverified suppliers typically provide little to no after-sales support or warranty. This leaves buyers without recourse if problems arise. Always choose suppliers with a proven track record and positive industry reputation.

Neglecting Proper Installation and Maintenance

Ignoring correct installation and consistent maintenance significantly reduces a brass solenoid valve’s lifespan and reliability. Manufacturers design valves for specific operating conditions. Deviating from these guidelines leads to premature failure. Improper installation often causes immediate issues. For example, incorrect pipe alignment stresses the valve body. This creates leaks or internal damage. Overtightening connections also cracks the brass housing. Electrical connections must match the valve’s voltage and current requirements. Incorrect wiring burns out the coil.

Following manufacturer instructions is crucial. These instructions detail proper mounting orientation, torque specifications, and electrical hook-ups. They ensure the valve operates as intended. A clean media supply is also vital. Contaminants like dirt or debris clog the valve’s internal mechanisms. This prevents proper opening and closing. Install filters upstream of the valve to prevent such issues.

Regular maintenance extends the valve’s operational life. It also prevents unexpected breakdowns. Maintenance tasks include inspecting for leaks, checking electrical connections, and cleaning internal components. Periodically, technicians should replace worn seals or O-rings. This prevents fluid bypass and maintains sealing integrity. Lubricating moving parts, if applicable, ensures smooth operation.

A proactive maintenance schedule identifies potential problems early. This allows for timely repairs. It avoids costly downtime. Neglecting these steps leads to frequent valve replacements. It also increases operational expenses. Proper care ensures the brass solenoid valve delivers consistent, reliable performance throughout its expected service life.

💡 Tip: Always refer to the valve’s specific manual for detailed installation and maintenance procedures. Each model may have unique requirements.

Understanding Application Needs for Brass Solenoid Valves

Selecting the correct solenoid valve requires a clear understanding of the application’s specific demands. Matching the valve’s capabilities to these needs ensures optimal performance and longevity.

Pressure and Temperature Ratings

Every solenoid valve has specific pressure and temperature limits. Users must ensure the valve’s rated pressure range comfortably handles the system’s maximum operating pressure. Similarly, the valve’s temperature rating must accommodate the media’s minimum and maximum temperatures. Exceeding these limits can lead to valve failure, leaks, or unsafe operating conditions. Always check the manufacturer’s specifications to confirm compatibility with your system’s pressure and temperature extremes.

Media Compatibility

The type of media flowing through the valve dictates the materials required for its construction. Brass solenoid valves are compatible with many common media. These include water, air, fuel, hot water, gas, diesel fuel, and Freon. They also work with weak acids and weak alkalis. This makes them suitable for various applications such as water systems, air control with minimal moisture, low-pressure steam, automotive fluid management, and oil. Manufacturers design these valves to handle both liquids and gases effectively, preventing corrosion or degradation of internal components.

Flow Rate Requirements

Properly sizing a solenoid valve involves understanding the required flow rate. The flow rate (Q) is crucial for calculating the valve’s Cv rating, a standard method for industrial valve sizing. The formula for Cv is: Cv = Q √(SG / ΔP). Here, Q represents the flow rate in gallons per minute, SG is the fluid’s density ratio compared to water, and ΔP is the pressure drop across the valve in psi. Different steam types, like wet, dry, or saturated steam, require specific Cv values to ensure efficient operation. For instance, wet steam needs a slightly lower Cv than dry steam. To size a valve, specify variables like flow rate, fluid type, pressures, and temperature. Then, determine constants like piping geometry factor (FP) and liquid pressure recovery factor (FLP). Finally, calculate the required flow coefficient (Cv).

Electrical Specifications

Matching the electrical specifications of a brass solenoid valve to the power supply is crucial for reliable operation. Manufacturers design valves to operate within specific voltage and current parameters. Supplying the incorrect voltage can lead to coil burnout or insufficient magnetic force, causing the valve to malfunction.

Consider these typical power consumption figures for industrial brass solenoid valves:

- Small 2-way electric solenoid valves operating at 12 volts might consume around 1-2 watts of power.

- Larger 2-way electric solenoid valves operating at 24 volts could consume 5-10 watts or more.

- Medium-sized 3-way manifold valves might consume around 3-8 watts when in operation.

- Air-actuated solenoid valves typically consume around 2-5 watts when the solenoid is energized.

A typical 24V solenoid valve may have a power consumption of 5 watts, drawing approximately 0.21 amps of current. A high-efficiency solenoid valve designed for intermittent use might consume only 2 watts. A larger industrial solenoid valve operating at 120V may consume 20 watts. Always verify the valve’s rated voltage (AC or DC) and power consumption. This ensures compatibility with the control system.

Environmental Considerations

The operating environment significantly impacts a brass solenoid valve’s performance and lifespan. Harsh conditions require specific materials and protective measures.

Key environmental factors to consider include:

- Temperature Extremes: Both high and low temperatures affect seal flexibility, coil resistance, and internal mechanical clearances. High temperatures can soften or deform seals and overheat coils. Freezing conditions can cause moisture to expand, leading to cracking or blockages.

- Corrosive Fluids/Chemicals: Long-term exposure to corrosive fluids or aggressive chemicals can degrade valve materials. Brass, for example, may not resist them effectively.

- UV Radiation: Prolonged exposure to UV radiation can lead to material degradation.

- Moisture/Dust: Ingress of moisture or dust can interfere with operation. This necessitates weather-resistant enclosures, such as those with an IP65 rating or higher.

- Vibration: Excessive vibration can compromise materials and seals over time.

Brass has moderate corrosion resistance. It suits water, air, and non-corrosive fluids. However, it may not be ideal for aggressive chemicals. Stainless steel offers more corrosion resistance. It suits demanding industrial environments. Seal materials like EPDM, NBR, and Viton each have unique strengths regarding temperature and chemical exposure. Using incompatible materials can lead to swelling, cracking, or corrosion, shortening the valve’s life.

Ensuring Long-Term Performance of Brass Solenoid Valves

Regular Inspection and Cleaning

Regular inspection and cleaning significantly extend the lifespan of brass solenoid valves. Operators should routinely check valves for visible signs of wear, corrosion, or leaks. They must also inspect electrical connections for integrity. Dirt, debris, or scale buildup inside the valve can impede its operation. Therefore, periodic cleaning of internal components prevents blockages and ensures smooth functionality. Following a consistent maintenance schedule helps identify potential issues early. This proactive approach prevents costly breakdowns and maintains optimal system performance.

Proper Storage Conditions

Correct storage practices are crucial for preserving brass solenoid valves not currently in use. Before storage, individuals must thoroughly clean the valve. They remove dirt, debris, or contaminants from the exterior using a mild detergent and soft brush. For the interior, they follow manufacturer instructions for specialized cleaning solutions. They rinse the valve thoroughly and dry it completely to prevent rust and corrosion. For brass solenoid valves, such as the 24V Brass Irrigation Control, applying a thin layer of lubricant to moving parts helps prevent rust and corrosion. Brass is susceptible to these issues if not stored properly.

💡 Tip: Store valves in a clean, dry, and temperature-controlled environment. Avoid direct sunlight, extreme temperatures, or high humidity. These conditions degrade valve materials. A climate-controlled facility, storage cabinet, or sealed container with good ventilation is ideal.

Individuals should protect the valve from physical damage by placing it securely. Foam padding or protective cases prevent knocking or bumping. If storing multiple valves, separate them with dividers or individual compartments. Keep the valve sealed using protective caps or plugs for inlet and outlet ports. If these are unavailable, use clean plastic bags or tape, ensuring no residue remains. Label the valve with its model number, serial number, and storage date for easy identification and history tracking. Regularly inspect stored valves for signs of damage like rust, corrosion, or cracks. Inspect seals and gaskets for wear or damage, replacing them as needed to prevent leaks.

Adhering to Manufacturer Guidelines

Following manufacturer guidelines is paramount for ensuring the long-term performance of brass solenoid valves. Manufacturers provide specific instructions for installation, operation, and maintenance. These guidelines detail correct mounting orientations, torque specifications for connections, and appropriate electrical hook-ups. Deviating from these instructions can lead to premature failure, reduced efficiency, or safety hazards. For example, incorrect wiring can burn out the coil. Ignoring recommended service intervals can cause internal components to wear out prematurely. Adhering to these guidelines ensures the valve operates within its designed parameters. This maximizes its lifespan and maintains system reliability.

Recognizing Signs of Wear and Failure

Recognizing the early signs of wear and failure in brass solenoid valves prevents costly downtime. Operators should regularly inspect valves for common indicators. Visible leaks around the valve body or connections often signal seal degradation or structural damage. Corrosion on the brass housing or electrical terminals indicates environmental exposure or chemical incompatibility. A valve that fails to open or close completely suggests internal mechanical issues or a faulty coil.

Audible cues also provide important clues. An unusual buzzing or humming sound from the coil might indicate an electrical problem or a loose component. A valve that clicks but does not actuate suggests a stuck plunger or insufficient power. Performance degradation, such as slow response times or inconsistent flow, points to internal wear, debris accumulation, or a weakening coil. Addressing these signs promptly extends the valve’s operational life and maintains system efficiency.

Availability of Spare Parts

Ensuring the availability of spare parts is crucial for the long-term performance and maintainability of brass solenoid valves. Manufacturers often provide a list of common wear parts. These typically include seals, O-rings, plungers, and coils. Buyers should confirm that suppliers can readily provide these components. This prevents extended downtime during maintenance or repairs.

Standardized parts offer a significant advantage. They are often easier to source from multiple vendors. Some manufacturers also offer repair kits. These kits contain all necessary components for routine servicing. Before purchasing, inquire about the lead time for spare parts. Also, ask about the expected lifespan of critical components. A reliable supplier supports their products with accessible and affordable spare parts. This commitment ensures the valve remains operational for its intended service life.

Yuyao No.4 Instrument Factory (Y4), Ningbo Kailing, and Zhejiang Sanhua consistently offer reliable Chinese Brass Solenoid Valve options. Other brands like Ningbo Huarui and Zhejiang Xinhong also provide strong performance. The “most reliable” choice ultimately depends on your specific application and thorough due diligence. Focus on key reliability factors and verify supplier credentials. This approach ensures you confidently select a high-quality Chinese brand of brass solenoid valves that meets your operational needs.

FAQ

What makes a Chinese brass solenoid valve reliable?

Reliability stems from high-quality materials, precise manufacturing, and strict quality control. Leading Chinese brands invest in these areas. They ensure their valves perform consistently and durably across various industrial applications.

Why are certifications important for brass solenoid valves?

Certifications like CE, RoHS, and UL confirm a valve’s quality, safety, and environmental compliance. They assure users the product meets international standards. These certifications are crucial for market acceptance and operational safety.

When should one choose brass over other materials for solenoid valves?

Brass valves suit applications with water, air, fuel, and non-corrosive fluids. They offer good performance in moderate pressure and temperature ranges. For aggressive chemicals or extreme conditions, stainless steel or other specialized materials are often better choices.

How can users ensure the long-term performance of brass solenoid valves?

Regular inspection, cleaning, and adherence to manufacturer guidelines are essential. Proper storage conditions and timely replacement of worn parts also contribute to extended lifespan. Proactive maintenance prevents unexpected failures and maintains efficiency.

Do Chinese manufacturers offer good after-sales support for brass solenoid valves?

Many reputable Chinese manufacturers provide robust after-sales support. This includes technical assistance, warranty coverage, and spare parts availability. Buyers should verify these services before making a purchase to ensure long-term operational success.