A 2/2 Way Solenoid Valve precisely controls fluid flow. It operates by switching between two distinct states: open and closed. Electrical signals dictate its operational state, enabling automated control. Understanding What is the working principle of a 2/2-way solenoid valve? reveals its fundamental role in many systems. The market for these valves, whether a robust Brass Solenoid Valve or a specialized 2/2 Ways Stainless Steel Solenoid Valve, shows strong growth. Experts project the direct operated solenoid valve market, which includes a 2/2 Ways Brass Solenoid Valve, will experience a compound annual growth rate of 6-8% over the next decade. This growth highlights the importance of knowing What is the operating principle of a 2/2 way solenoid valve?.

Key Takeaways

- A 2/2-way solenoid valve controls fluid flow. It has two ports for fluid and two positions: open or closed.

- The solenoid uses electricity to create a magnetic field. This field moves a plunger to open or close the valve.

- Valves can be normally closed (blocks flow without power) or normally open (allows flow without power).

- Key parts include the valve body, solenoid coil, plunger, valve seat, and seal. Each part has a special job.

- Direct-acting valves use the solenoid to move the valve directly. Pilot-operated valves use fluid pressure to help move the valve.

Understanding 2/2 Way Solenoid Valves

Defining Ports and Positions

A 2/2 Way Solenoid Valve manages fluid flow. To understand how it works, one must first grasp the concepts of "ports" and "positions." In fluid control systems, a port is simply an opening where fluid enters or exits the valve. The size of this opening significantly impacts how much fluid flows, how much pressure drops, and how energy is used. For instance, a full port valve has an opening as wide as the pipe, allowing fluid to move freely with minimal pressure loss. A standard port valve has a slightly narrower opening, offering good control with some pressure reduction. A reduced port valve has a much smaller opening, intentionally limiting flow and pressure for precise control. ISO 11727 provides clear definitions and rules for marking these ports on valves, covering supply, exhaust, and control connections.

"Positions" refer to the operational states of the valve. A 2/2-way valve has two positions: open and closed. The valve either allows fluid to pass through or completely blocks its path.

The Solenoid’s Role in Control

The solenoid is the crucial component that controls these positions. It acts as an electromagnetic coil, converting electrical energy into a linear mechanical force. When electric current flows through the solenoid’s coiled copper wire, it generates a magnetic field. This electromagnetic force then transforms magnetic energy into mechanical motion. It does this by attracting or repelling a magnetic plunger. The plunger moves within its housing, creating the necessary mechanical action to open or close the valve. This fundamental principle of electromagnetism allows the solenoid to precisely switch the valve between its open and closed states, controlling the fluid path with electrical signals.

Key Components of a 2/2-Way Solenoid Valve

The Valve Body and Fluid Ports

The valve body forms the main housing of a 2/2-way solenoid valve. It contains the fluid ports, which are the entry and exit points for the fluid. Manufacturers select body materials carefully to ensure durability and chemical resistance. For instance, chromium-molybdenum steel offers superior corrosion resistance, especially with high-temperature steam or fluids containing sulfur. Alloy C-276, a nickel-chromium-molybdenum alloy, provides superb corrosion resistance for chemical pipelines. Other common materials include brass, titanium, polyvinyl chloride (PVC), and polypropene. For highly aggressive chemicals, high-alloy metals like Hastelloy or titanium are often chosen. Thermoplastic valves, made from materials such as PVC or polypropylene, resist a wide range of acids and alkalis.

These valve bodies must also withstand specific pressures. For water, they typically handle pressures from 0-145 PSI, and for air, from 7-145 PSI. However, specialized valves offer higher capabilities. Standard operating coils can manage pressures from 6 to 230 PSI. Medium pressure options extend to 725 PSI, and high-pressure versions can handle up to 1160 PSI.

The Solenoid Coil and Plunger

The solenoid coil is the heart of the valve’s electrical operation. It consists of many turns of wire, usually enameled copper wire. Copper is a popular choice because of its excellent electrical conductivity, which efficiently converts electrical current into a magnetic field. This minimizes power loss and reduces overheating. Sometimes, manufacturers use alternative materials like aluminum or copper-clad aluminum (CCA wire) to meet specific performance or cost targets. The coil often uses insulation like polyester or polyamide-imide for electrical protection and heat resistance.

Inside the coil sits the plunger, a movable magnetic core. When electricity flows through the coil, it generates a magnetic field. This field pulls the plunger, causing it to move. This mechanical movement is what opens or closes the valve.

The Valve Seat and Seal

The valve seat and seal are critical components that ensure tight shut-off and prevent fluid leakage. The valve seat provides a surface for the seal to rest against, creating a barrier when the valve is closed. The seal material must be compatible with the fluid and withstand operating temperatures and pressures.

Many materials are available for valve seats and seals. PTFE (Teflon) offers excellent chemical resistance and works well across a wide temperature range, making it suitable for chemical processing. EPDM is a good choice for water, steam, and alcohol applications. NBR (Nitrile Butadiene Rubber) performs well with oils and fuels. For more demanding chemical environments, Viton provides excellent resistance. For extremely high temperatures and pressures, metal seals like stainless steel or tungsten carbide are used. These materials offer durability and reliability.

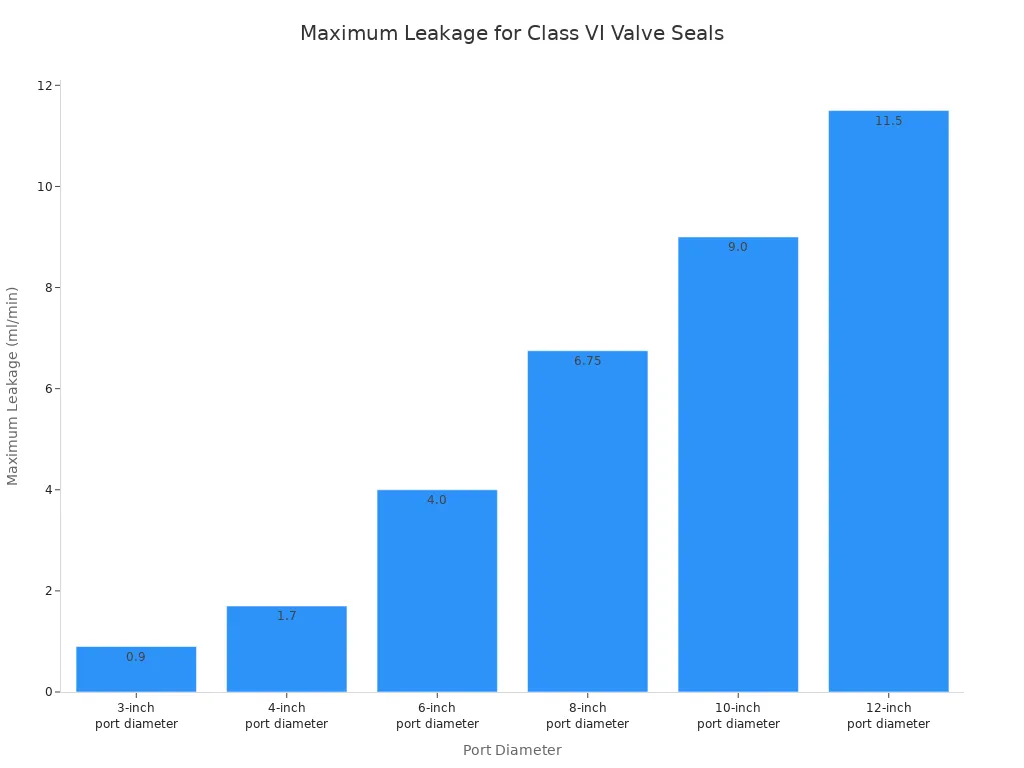

High-quality seals ensure minimal leakage. For example, Class VI seals, a common standard, allow very little fluid to pass. The maximum allowable leakage for a Class VI seal depends on the port diameter:

This strict standard ensures the valve effectively controls fluid flow without unwanted drips or losses.

How 2/2 Way Solenoid Valves Operate When De-energized

A 2/2 Way Solenoid Valve’s default state, or its behavior when it receives no electrical power, defines its fundamental operation. This de-energized state determines whether the valve allows fluid to pass or blocks it. Manufacturers design these valves for specific applications, making their default state crucial for system safety and function.

Normally Closed Valve Operation

A normally closed (NC) valve remains closed when de-energized. In this state, a spring holds the plunger firmly against the valve seat. This action creates a tight seal, which prevents any fluid from flowing through the valve. The valve acts like a barrier, stopping the fluid path until it receives an electrical signal.

Normally closed 2/2-way valves are often the preferred choice in many applications. They are crucial in systems where fluid flow must stop during a power failure. For example, they manage the flow of liquids or gases in automated fluid control systems. They also control compressed air in pneumatic systems. In fuel systems, these valves ensure fuel flow halts when the system is not operational, providing a vital fail-safe mechanism. They are essential for preventing leaks and spills in hazardous applications, such as fuel delivery or chemical processing. These valves also work well for applications that require frequent opening and closing, offering enhanced control and reliability.

You find normally closed 2/2-way valves in various settings:

- Medical, Laboratory & Pharmaceutical Equipment: They provide precision dosing, manage clean media flow, and offer rapid shutoff in devices like oxygen concentrators, gas chromatographs, and chemical wash cycles.

- Fuel Delivery, LPG, and Oil Burner Systems: In fuel stations or generators, they ensure fail-safe fuel shutoff by remaining closed until powered.

- General-Purpose Industrial Automation: They offer basic open/close control in applications such as commercial dishwashing and laundry machines, bottle filling lines, and chemical dosing in wastewater treatment.

Normally Open Valve Operation

Conversely, a normally open (NO) valve remains open when de-energized. Here, the spring holds the plunger away from the valve seat. This position allows fluid to flow freely through the valve without any electrical input. The valve maintains an open path for the fluid until an electrical signal actively closes it. This configuration is useful in systems where continuous flow is the default, and you only need to stop the flow occasionally.

Fluid Flow in the De-energized State

The de-energized state dictates the initial fluid flow. For a normally closed valve, no fluid flows. The valve effectively blocks the path. For a normally open valve, fluid flows freely. The valve offers no resistance to the fluid’s movement. This default behavior is a critical design consideration. It ensures system safety and efficiency, especially in situations where power loss might occur. Engineers select the appropriate valve type based on whether they need to stop or allow fluid flow by default.

How 2/2 Way Solenoid Valves Operate When Energized

When you apply electrical power to a 2/2 Way Solenoid Valve, a fascinating process begins. This action reverses the valve’s de-energized state, allowing it to control fluid flow precisely. The valve transitions from its default position to its active, energized state.

Generating the Electromagnetic Field

The moment electricity reaches the solenoid coil, it transforms into a powerful electromagnet. The current flows through the coil’s wire windings, creating a magnetic field around it. This field is the driving force behind the valve’s operation. The speed at which this field forms is quite impressive. A solenoid coil typically generates a sufficient electromagnetic field within 5 to 50 milliseconds. This quick response time is crucial for systems needing precise and rapid control.

The power consumption of these coils varies depending on their size and design. For instance, smaller 2-way electric solenoid valves, like those operating on 12 volts, might use only about 1 to 2 watts. Larger 24-volt valves, however, can consume 5 to 10 watts or even more. Medium-sized 3-way manifold valves typically use 3 to 8 watts when operating. Air-actuated solenoid valves, focusing on the solenoid part, usually draw around 2 to 5 watts when energized. Once the valve moves into position, its power consumption often drops significantly.

Plunger Movement and Fluid Control

As the electromagnetic field strengthens, it exerts a strong pull on the plunger. This plunger, made of a magnetic material, moves rapidly into the center of the coil. The force generated by the energized solenoid on its plunger is quite substantial, often around 15 Newtons (N), which equals about 3.4 pounds-force (lbf). This mechanical force is what directly controls the valve’s state.

The plunger’s movement is precise and swift. It either lifts away from the valve seat or pushes down onto it, depending on the valve’s design. This action directly opens or closes the fluid path.

Switching the Fluid Path

The plunger’s movement effectively switches the fluid path. If you have a normally closed valve, the energized coil pulls the plunger away from the valve seat. This action opens the valve, allowing fluid to flow through. Conversely, if you have a normally open valve, the energized coil pushes the plunger down onto the valve seat. This closes the valve, stopping the fluid flow. The valve holds this new position as long as the electrical current flows through the coil. When the power is removed, the spring returns the plunger to its original, de-energized state. This simple yet effective mechanism allows for reliable and automated control of liquids and gases in countless applications.

Types of 2/2 Way Solenoid Valves

Solenoid valves come in different designs. Each design suits specific application needs. Understanding these types helps you choose the right valve for your system.

Direct Acting Mechanism

Direct-acting solenoid valves are straightforward. They use the solenoid’s electromagnetic force to directly open or close the valve. This means they do not need any minimum pressure difference to operate. This makes them perfect for systems with low or even no pressure. For example, some Burkert Type 6024 direct-acting valves can work with a minimum pressure of 0.00 bar. STC 2P Series valves, which are normally closed and direct-acting, also do not require any minimum differential pressure.

These valves offer quick response times. They provide immediate control over fluid flow. This is ideal for systems needing rapid switching. Direct-acting valves also have fewer moving parts. This leads to better durability and less maintenance. They are also more tolerant of impurities. Their simpler flow path makes them suitable for applications where media cleanliness is not always guaranteed. You can find direct-acting 2/2-way solenoid valves like the SMC V100 series. These offer flow rates from 8.4 to 24 liters per minute.

Pilot Operated Mechanism

Pilot-operated solenoid valves work differently. They use the system’s fluid pressure to assist in opening or closing the main valve. The solenoid first opens a small "pilot" orifice. This releases pressure from one side of a diaphragm or piston. The pressure difference then moves the main valve.

Pilot-operated valves typically require a minimum pressure differential to function correctly. This is usually around 5-10 PSI. This requirement is crucial for their proper operation. Insufficient differential can cause the valve to work improperly or move slowly. The exact pressure needed can vary. Factors like valve size, spring force, and overall design play a role. Always check the manufacturer’s specifications for the best performance. These valves are often chosen for higher flow rates and pressures. They can handle larger volumes of fluid more efficiently than direct-acting valves.

A 2/2-way solenoid valve fundamentally controls fluid flow. It uses an electrical signal to create an electromagnetic field. This field moves a plunger, which then opens or closes the valve. This simple yet effective mechanism allows precise control of liquids and gases.

The interplay of components like the solenoid coil, plunger, valve seat, and seal ensures accurate operation. Choosing the right valve is crucial for its lifespan and performance. For example, high-quality materials resist wear, and proper selection for media type, pressure, and temperature prevents early failure. Regular maintenance also helps these valves work precisely for a long time.

FAQ

What does "2/2-way" mean for a solenoid valve?

A 2/2-way valve has two ports for fluid entry and exit. It also has two positions: open or closed. This means the valve either allows fluid to pass or completely blocks its path. This simple design makes it very common for basic on/off control.

What is the difference between normally closed and normally open valves?

A normally closed valve stays shut when de-energized, stopping fluid flow. A normally open valve remains open without power, letting fluid pass. Power changes their state. Engineers choose the type based on whether they need fluid to flow or stop by default.

How does a direct-acting valve differ from a pilot-operated valve?

Direct-acting valves use the solenoid to move the valve directly. They work with no pressure. Pilot-operated valves use fluid pressure to help open or close the main valve. They need minimum pressure to operate. Pilot valves handle higher flow rates.

What materials are used for valve bodies and seals?

Valve bodies often use brass, stainless steel, or PVC for durability. Seals use materials like PTFE, EPDM, or NBR. Manufacturers choose materials based on fluid type, temperature, and pressure requirements. This ensures the valve works correctly and lasts a long time.