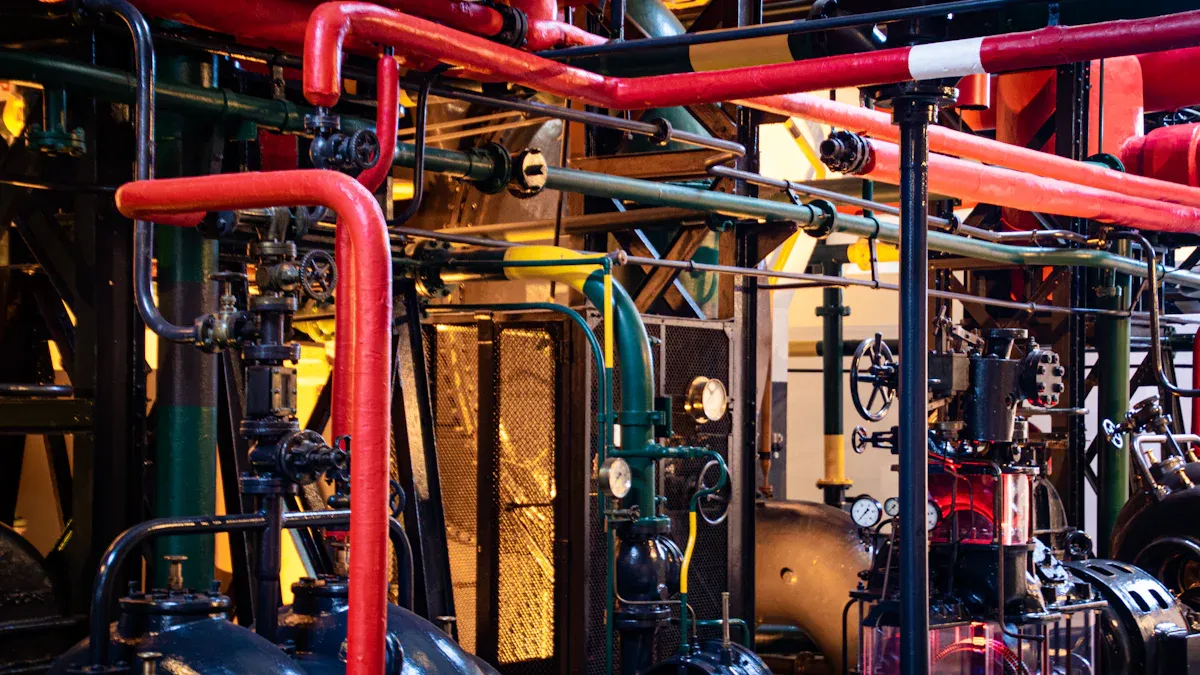

Incorrect Solenoid Valves selection causes big problems. These choices lead to operational inefficiencies. They also cause system failures and higher costs. For example, using a Direct Acting Solenoid Valve when a Pilot Operated Valve is needed can ruin a system. Choosing the right Stainless Steel Solenoid Valves or brass solenoid valves is key. A 2/2 Way Solenoid Valve might not be enough for complex flows. You need informed decisions to future-proof projects for 2026.

Key Takeaways

- Understand your needs before choosing a valve. Consider what flows through it, the pressure, and the temperature.

- Pick the right valve type. Decide if you need a direct-acting or pilot-operated valve, and if it should be normally open or closed.

- Check valve details like size, materials, and power. These help the valve work correctly and last longer.

- Look for quality and good support. Choose valves from trusted makers with certifications and warranties.

- Plan for the future. Think about how much the valve will cost over time, its energy use, and if it can grow with your system.

Understanding Your Application for Solenoid Valves

Choosing the right valve begins with a deep understanding of its intended use. People often overlook crucial details, leading to costly mistakes. A thorough assessment of your application ensures optimal performance and longevity for your system.

Identifying Media Type and Compatibility

First, consider what flows through the valve. This "media" can be a liquid or a gas. Different media require specific valve materials to prevent corrosion or damage. For example, common media types in industrial processes include:

- Liquids:

- Water (clean)

- Oils (varying viscosities, with potential additives or contaminants)

- Chemicals (acids, bases, solvents, with different levels of corrosiveness)

- Gases:

- Air (clean, dry, often compressed)

- Natural Gas

- Propane

- Oxygen (highly reactive)

- Nitrogen

- Argon

Matching the valve’s body and seal materials to the media is critical. Incompatible materials can quickly degrade, causing leaks and system failure.

Defining Pressure and Flow Requirements

Next, evaluate the pressure and flow rates your system demands. These factors directly influence valve size and type. Here is a look at typical ranges:

| Category | Range (bar) | Range (psi) | Additional Details |

|---|---|---|---|

| Minimum Pressure Difference (Indirect Operation) | 0.95 to 2 | 13.77 to 29 | Required for indirect operation pneumatic solenoid valves |

| Maximum Pressure (Pneumatic) | 7 to 12 | 101 to 174 | Ensures efficient operation of pneumatic cylinders |

| Kv Value (Flow Capacity) | 1 to 4 m³/h | N/A | Indicates air flow rate at 1 bar pressure drop; higher Kv means greater flow capacity |

| Required Flow Rate | N/A | N/A | Valve’s flow rate must exceed the system’s required air flow |

The valve’s flow capacity, often measured by its Kv value, must exceed the system’s required air flow. This ensures efficient operation.

Considering Temperature Range and Environmental Factors

Finally, think about the environment where the valve will operate. Extreme temperatures and harsh conditions significantly impact valve performance and material selection.

- Impacts of Cold Temperatures:

- Fluid viscosity changes: Liquids become thicker, leading to sluggish performance.

- Hardened seals: Seals lose elasticity, become brittle, and may fail.

- Material contraction: Metals and elastomers contract, affecting sealing.

- Impacts of Hot Temperatures:

- Overheating: Continuous use generates heat, damaging elastomers and electrical components.

- Seal degradation: Extreme heat alters molecular structure of elastomers, accelerating aging.

- Low viscosity: Hot fluids can have lower viscosity, potentially leading to unstable function.

To counter these issues, people select valves made of appropriate materials like stainless steel or elastomers rated for specific temperatures. For cold environments, insulation or heating elements can prevent freezing. In hot environments, proper ventilation and heat-resistant materials like fluorocarbon elastomers are essential. Dirty or humid environments also require special consideration to prevent clogging or corrosion.

Assessing Specific System Demands

Beyond the basic media, pressure, and temperature, every system has unique needs. Ignoring these specific demands often leads to unexpected problems and higher costs later on. Consider these factors carefully for a successful installation.

First, think about the valve’s duty cycle. How often will the valve open and close? A valve operating continuously needs a more robust design than one that cycles only a few times a day. Continuous operation generates heat and causes wear. This requires materials and designs built for endurance.

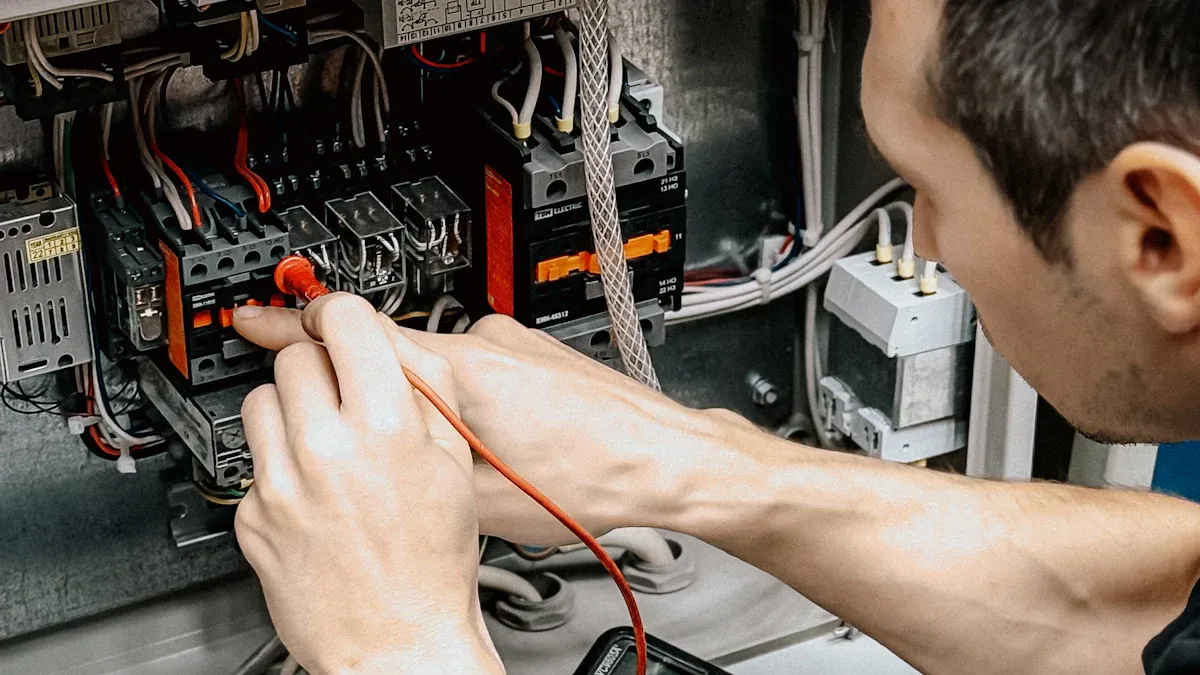

Next, evaluate power availability. Does the system use AC or DC power? What voltage is available? The valve’s coil must match the power supply exactly. Mismatched power can burn out the coil or prevent proper operation. Some applications might need low-power options for energy efficiency or battery operation.

Safety requirements are also paramount. Does the environment contain flammable gases or dust? If so, you need explosion-proof valves with specific certifications. These valves prevent sparks that could ignite hazardous atmospheres. Always check for relevant industry standards and local regulations.

Consider maintenance access. How easy is it to reach the valve for inspection or repair? A valve placed in a hard-to-reach spot increases maintenance time and costs. Design the system with accessibility in mind. This makes future servicing much simpler.

Finally, think about integration with control systems. Will the valve connect to a Programmable Logic Controller (PLC) or other automation? Some valves offer advanced communication features. These features allow for precise control and feedback. Ensure the valve you choose can seamlessly integrate with your existing or planned control architecture. This ensures smooth operation and efficient system management.

Selecting the Right Solenoid Valve Type

Choosing the correct solenoid valve type is a crucial step. Different applications demand different valve designs. Understanding these distinctions helps you make an informed decision.

Direct-Acting vs. Pilot-Operated Solenoid Valves

When you select a valve, you often encounter direct-acting and pilot-operated types. They work differently. A direct-acting valve uses the solenoid’s force to directly open or close the main seal. It works well from zero pressure up to its maximum rating. These valves are typically for smaller orifice sizes, like up to 3/4 inch. They also offer faster response times.

| Feature | Direct-Acting Solenoid Valves | Pilot-Operated Solenoid Valves |

|---|---|---|

| Operational Principle | The solenoid directly acts on the valve’s main seal. | The solenoid acts on a small pilot valve, which then controls a larger main valve. |

| Pressure Requirement | Can operate from zero pressure. | Requires a minimum pressure differential. |

| Power Consumption | Generally consume more power for larger orifices. | Generally consume less power for larger orifices. |

| Orifice Size | Typically for smaller orifice sizes (e.g., up to 3/4 inch). | Can handle much larger orifice sizes (e.g., 1 inch and above). |

| Response Time | Faster response times. | Slower response times. |

| Typical Applications | Low-pressure systems, small flow rates, medical equipment. | High-pressure systems, large flow rates, industrial process control. |

Pilot-operated valves work differently. The solenoid first opens a small pilot valve. This then uses the medium’s pressure to open or close the main valve. These valves need a minimum pressure difference to work. They handle much larger orifice sizes, often 1 inch and above. They also consume less power for larger flows. However, they have slower response times.

Normally Open vs. Normally Closed Configurations

Solenoid valves come in two main configurations: normally open (NO) and normally closed (NC). This refers to their state when they have no power. A normally closed valve stays shut when de-energized. It opens only when you apply power. This is useful for safety systems, like stopping fuel flow during a power outage. A normally open valve stays open when de-energized. It closes when you apply power. People use these in cooling systems or fire suppression, where continuous flow is important even without power.

- Normally Closed (NC) Use Cases:

- Fluid control systems: Starting and stopping liquid or gas flow.

- Fuel systems: Stopping fuel flow when the system is off.

- Fail-safe applications: Preventing leaks during power failures.

- Normally Open (NO) Use Cases:

- Safety systems: Ensuring water or extinguishing agents are always available.

- Cooling systems: Maintaining coolant flow to prevent overheating.

- Emergency drains: Releasing pressure when power fails.

Choosing 2-Way, 3-Way, or 4-Way Solenoid Valves

The number of ways a valve has refers to its ports and flow paths.

- 2-Way Valves: These are simple on/off valves. They have one inlet and one outlet. They either allow flow or stop it. People use them for basic on/off applications, like in irrigation systems or process safety.

- 3-Way Valves: These valves have three ports. They can switch flow between two different circuits or mix/divert fluids. You might find them in crop spraying to switch chemicals or in heating and cooling systems.

- 4-Way Valves: These valves have four ports. They create two states or actions with two exhaust ports. This allows for speed control of each action. They are common in pneumatic applications, especially for controlling cylinders.

| Valve Type | Common Applications |

|---|---|

| 2-Way | On/off applications, irrigation systems, venting applications. |

| 3-Way | Switching between two circuits, mixing/diverting fluids, fertilizer mixing. |

| 4-Way | Creating two states/actions with two exhaust ports, pneumatic applications. |

Proportional Control for Solenoid Valves

Sometimes, a simple on/off action is not enough. You need precise control over flow or pressure. This is where proportional control comes in. These specialized valves do not just open or close completely. Instead, they can open to any position between fully closed and fully open. This gives you much finer command over the fluid or gas moving through your system.

How do they achieve this? A proportional valve uses a variable electrical signal. This signal tells the valve exactly how much to open. Think of it like a dimmer switch for lights, but for fluid flow. The valve’s internal components move to a precise position based on the signal. This allows for very accurate adjustments.

💡 Tip: Proportional control offers superior precision compared to standard on/off valves. This precision can lead to better process quality and reduced waste.

You will find proportional control valves in many advanced applications. For example, they are crucial in HVAC systems that need exact temperature regulation. Medical devices often use them for precise fluid delivery. Industrial automation also relies on them for tasks like mixing ingredients or controlling robotic movements. They help maintain stable conditions and optimize performance.

Choosing a proportional valve means considering a few extra factors. They are generally more complex and cost more than basic on/off valves. You also need a control system that can send the variable signals. However, the benefits of precision, smoother operation, and potential energy savings often outweigh these initial considerations. They offer a sophisticated solution for demanding control needs.

Key Specifications for Solenoid Valves

Choosing the right valve means looking closely at its specifications. These details ensure the valve works correctly and lasts a long time in your system. Ignoring them can lead to poor performance or early failure.

Orifice Size and Port Connection Standards

The orifice size determines how much fluid or gas can pass through the valve. A larger orifice allows more flow. The port connection standards tell you how the valve connects to your piping. Common standards include NPT (National Pipe Taper) and BSP (British Standard Pipe). Different valve series offer various sizes and connection types. For example, some industrial Solenoid Valves come with these options:

| Valve Series | Orifice Size | Port Connection Standards |

|---|---|---|

| Series 4700 | 20mm to 25mm | 3/4” and 1” NPT |

| Series 3580 | 1/2” | 1/4″, 3/8” and 1/2” NPT |

| Series 3585 | 1/2” (12.5 mm) | 1/4”, 3/8” and 1/2” NPT or BSP |

| Series 35KR | 12mm | (manifold mounting) |

| Series 3680 | Full flow orifice | 3/4” and 1” NPT |

Always match the valve’s port size and standard to your existing plumbing. This prevents leaks and ensures proper flow.

Material Compatibility for Body and Seals

The materials used for the valve body and seals must withstand the media flowing through them. Corrosive chemicals or high temperatures demand special materials. Incompatible materials can quickly degrade, causing leaks and system failure. For instance, consider these materials for challenging conditions:

| Material | Type | Advantages | Disadvantages | Common Applications |

|---|---|---|---|---|

| Viton (FKM) | Fluoroelastomer (synthetic rubber) | Excellent resistance to chemicals and high temperatures | High cost, less flexible at low temperatures | Chemical processing, oil & gas, valves handling aggressive fluids |

| PTFE (Teflon) | Thermoplastic fluoropolymer | Supreme chemical resistance, very low friction | Lower mechanical strength, prone to creep (deformation under load) | Food & beverage, sanitary applications, highly corrosive substances |

Choosing the correct material ensures the valve’s durability and safe operation.

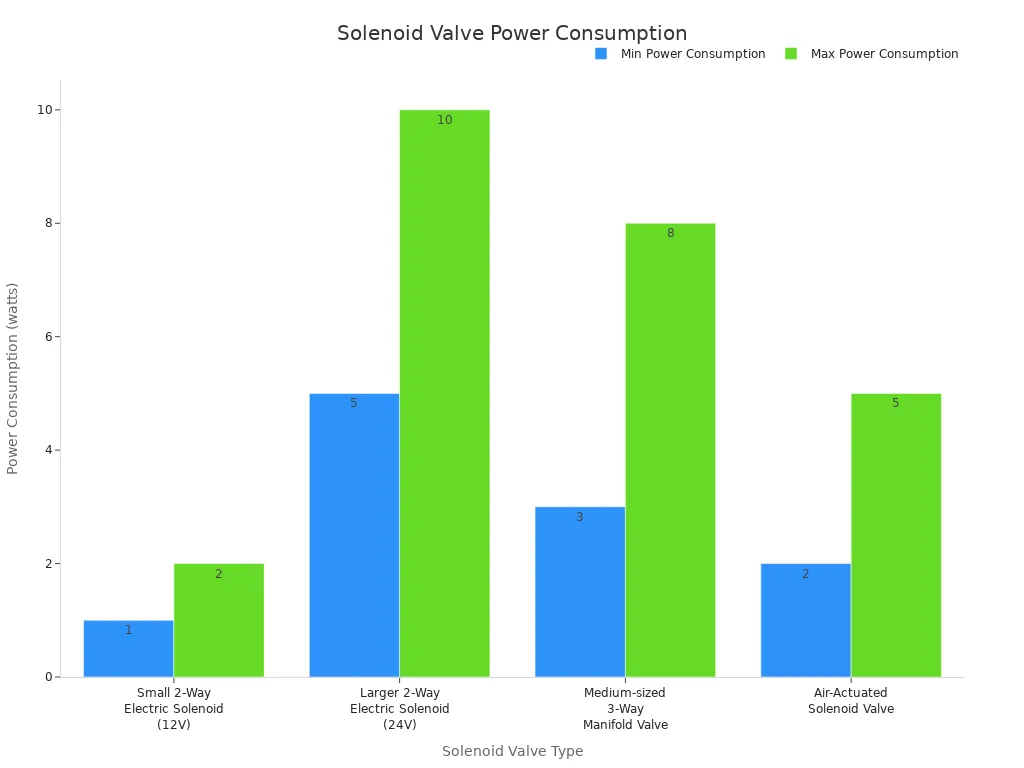

Voltage and Power Consumption of Solenoid Valves

Every solenoid valve needs a specific voltage to operate. You must match the valve’s coil voltage to your power supply. Common voltage ratings include 6V, 12V, 24V, 120V, and 220V. Smaller devices like home appliances often use coils operating at less than 24 volts. Factories and heavy machinery typically use coils above 24 volts.

The nominal voltage is the required voltage for a valve to operate. Manufacturers usually mark this on the valve body or coil. Most coils can tolerate a voltage within ±10% of their rated value. For example, a 220V AC coil typically functions between 198V and 242V.

Power consumption also varies. It depends on the valve’s size, operating voltage, and the number of coils. Higher-voltage valves generally consume more power. However, they can handle larger flow rates. Air-actuated valves primarily consume power when their solenoid is energized. Consumption drops significantly once the valve is in position.

| Solenoid Valve Type | Typical Power Consumption Range |

|---|---|

| Small 2-Way Electric Solenoid (12V) | 1-2 watts |

| Larger 2-Way Electric Solenoid (24V) | 5-10 watts or more |

| Medium-sized 3-Way Manifold Valve | 3-8 watts |

| Air-Actuated Solenoid Valve (solenoid energized) | 2-5 watts |

Understanding these power needs helps you design an efficient and reliable system.

Response Time and Cycle Rate Considerations

When you pick a valve, how fast it reacts matters a lot. This is its response time. It tells you how quickly the valve can switch from open to closed, or vice versa. Several things can slow a valve down. These include how electricity flows through its parts, how fast its magnetic field builds up, and even the physical movement of its internal pieces. Friction also plays a role. Typically, valves respond in about 5 to 50 milliseconds.

Different types of valves have different speeds. Small direct-acting valves are quite fast; they can respond in around 30 milliseconds. However, indirect-operated valves take much longer, sometimes 1000 milliseconds or more. Electric ball valves, which people often use in heating and cooling systems or for watering plants, usually take a few seconds to react.

Engineers have a standard way to measure this speed. The European Fluid Power Committee (C.E.T.O.P) set the rules. They measure opening time from when the valve gets power until its outlet pressure reaches 90% of its full level. For closing time, they measure from when the power turns off until the pressure drops to 10% of what it was. They usually do these tests with air at 6 bars and 20°C.

Beyond just speed, think about how often the valve needs to open and close. This is its cycle rate. A valve that cycles many times a minute needs to be much tougher than one that only operates a few times a day. High cycle rates put more stress on the valve’s parts. This means you need a valve built for endurance. Choosing the right valve for your required response time and cycle rate helps your system run smoothly and last longer.

Ensuring Quality and Reliability in Solenoid Valves

Choosing the right solenoid valve goes beyond just technical specifications. You also need to consider the quality and reliability of the product. This ensures your system runs smoothly for a long time.

Manufacturer Reputation and Industry Track Record

A manufacturer’s reputation tells you a lot about their products. Look for companies with a strong history in the industry. They often provide better quality and support. Consider these points when you evaluate a manufacturer:

- Product quality and certifications: They should have ISO-certified manufacturing. Their products should meet standards like CE, ATEX, or UL.

- Comprehensive product range: A wide selection of valve types shows their expertise.

- Technical expertise and support: Good suppliers offer engineering guidance and responsive customer service.

- Customization capabilities: They can provide custom solutions if your project needs them.

- Availability and lead times: Fast and reliable delivery helps keep your projects on schedule.

- Competitive pricing and warranty: Evaluate the cost against performance and warranty terms.

- Global reach and logistics: International suppliers can support large projects.

Certifications and Compliance for Solenoid Valves

Certifications prove a valve meets specific safety and quality standards. Different regions and applications require different certifications. Always check for the relevant ones for your project.

| Certification | Meaning/Organization | Region/Application | Key Requirements for Solenoid Valves |

|---|---|---|---|

| CE Certification | Conformité Européene (European Conformity) | European market | Meets essential health, safety, and environmental protection; includes proper insulation, pressure resistance, and Electromagnetic Compatibility (EMC) standards to minimize interference. |

| UL Certification | Underwriters Laboratories | North American market | Ensures product safety; checks electrical component quality, high-temperature resistance, and overall mechanical integrity. |

| ISO Certification | International Organization for Standardization | Various industries globally | ISO 9001 for quality management (design, production, testing, after-sales); ISO 14001 for environmental management (waste reduction, eco-friendly materials). |

| ATEX Certification | European directive for explosive atmospheres | Potentially explosive atmospheres (e.g., oil & gas, chemical, mining) | Designed to prevent ignition of explosive mixtures; may include flameproof enclosures or intrinsically safe electrical circuits. |

| FDA Standards | Food and Drug Administration | Food and beverage industry | Ensures safety for contact with food products. |

| Medical Device Regulations | European Medical Device Regulation (MDR), US FDA | Medical applications | Compliance with specific regulations for medical devices. |

These certifications ensure the solenoid valves are safe and reliable for their intended use.

Warranty and Technical Support for Your Solenoid Valves

A good warranty protects your investment. It shows the manufacturer stands behind their product. Look for clear warranty terms.

| Warranty Type | Duration/Coverage | Conditions/Limitations |

|---|---|---|

| Supplier Warranty | 3 months from delivery | Covers defects in material, workmanship, or design. Excludes improper alteration, misuse, unauthorized repair, improper installation, damage by fire/water/smoke, exceeding guarantee period, non-compliance with maintenance, or other reasons at supplier’s discretion. |

| Manufacturer Warranty | Varies by product | Limited to replacement of the product. Void if damaged by accident, unreasonable use, neglect, tampering, or causes not related to material/workmanship defects. Extends only to the original consumer purchaser. |

Technical support is also very important. You might need help with installation or troubleshooting. Reputable suppliers offer various support options:

- Over-the-phone support or diagnosis can be available.

- In-depth technical or analytical support may also be offered.

- On-site fault diagnosis is possible in certain situations.

Always confirm what support options a supplier provides. This ensures you get help when you need it.

Testing and Validation Processes for Solenoid Valves

After selecting a valve, you must ensure it performs as expected. Manufacturers put valves through rigorous testing and validation processes. This guarantees their integrity and structural strength. For example, high-purity valves undergo multiple tests after manufacturing and assembly. These tests use non-destructive methods to find surface defects. Such defects could cause contamination. Also, high-purity valves go through pressure and leak tests. These tests confirm they work well in contamination-sensitive fluid applications.

Manufacturers use several key tests to ensure quality and reliability:

- Cycle Testing: This test simulates thousands of opening and closing cycles. It evaluates the valve’s durability over time.

- Environmental Testing: This assesses how the valve performs under extreme conditions. It checks performance in very hot or cold temperatures, high pressures, and corrosive environments.

- Leak Detection: This ensures valves meet strict standards for preventing leaks. It is crucial for safety and efficiency.

- Functional Validation: This tests the valve’s compatibility with customer systems. It checks flow rate and pressure regulation.

- Performance Testing: Every valve undergoes testing under simulated operating conditions. This confirms it works correctly before leaving the factory.

- Visual Inspection: Technicians carefully inspect components. They ensure parts are free of defects and meet aesthetic standards.

- Batch Certification: Manufacturers certify each production batch. This confirms compliance with industry regulations.

These thorough testing procedures help ensure the valve you choose will perform reliably in your system. They give you confidence in the product’s quality and longevity.

Installation and Maintenance of Solenoid Valves

Proper installation and ongoing maintenance are crucial for any system. They ensure your Solenoid Valves perform reliably. Overlooking these steps can lead to unexpected downtime and higher costs.

Mounting Orientation and Space Requirements

Installing a valve correctly is vital for its long-term performance. Different Solenoid Valves offer various mounting options. You must ensure the chosen valve fits the available space in the system. Some valves can be mounted in any position. Others require specific orientations. Always check the manufacturer’s specifications. This confirms the valve installs easily and securely.

Consider these factors for installation:

| Factor/Orientation | Horizontal Installation | Vertical Installation |

|---|---|---|

| Gravity and Media Flow | Less impact on gases or low viscosity liquids. Can lead to slow opening/closing or incomplete sealing for liquids. | Assists liquid flow, improving response time and efficiency. |

| Coil Position | Higher risk of moisture accumulation. This can lead to corrosion and damage. | Less likely to accumulate moisture or debris. This extends coil lifespan. |

| Space Requirements | Space-saving in compact piping systems. | May require more vertical space. |

| Maintenance | Often easier to access for maintenance and inspection. | (Not explicitly mentioned as an advantage or disadvantage) |

For example, a Solenoid Valve Gas LPG typically installs horizontally. This ensures proper sealing and prevents gas leakage. Vertical installation can cause issues with internal components. A Pneumatic Steam Valve 2L Series often needs a specific orientation. This allows proper drainage of condensate. It also prevents water hammer. An IP68 Waterproof valve offers more flexibility. However, its electrical connections must remain protected.

Ease of Maintenance and Repair for Solenoid Valves

Think about how easy it is to maintain and repair your valves. Some designs allow quick access to internal components. Others require more effort. Choosing valves with simple designs can save time and money during servicing. Look for models where you can replace coils or seals without removing the entire valve from the pipeline. This minimizes disruption to your operations.

Availability of Spare Parts for Solenoid Valves

The availability of spare parts directly impacts your system’s uptime. Even the most robust valve may eventually need a replacement part. Ensure the manufacturer or supplier can provide common spare parts quickly. These include coils, seals, and diaphragms. A good supply chain for spare parts prevents long delays. It keeps your system running smoothly.

Expected Lifespan and Durability

A valve’s expected lifespan and durability are critical considerations. You want a valve that performs reliably for a long time. Several factors directly influence how long a valve lasts and how well it withstands tough conditions.

The quality of materials plays a huge role. High-quality, corrosion-resistant materials like stainless steel make valves much more durable. This is especially true in harsh environments. Cheaper materials, on the other hand, can break down too soon. Operating conditions also affect longevity. High temperatures cause components to expand and contract. Vibrations or shocks can loosen parts. All these factors reduce a valve’s service life. The frequency of use also matters. Valves that cycle often wear out faster than those used only sometimes. Regular maintenance, including cleaning, checking electrical connections, and finding problems early, can significantly extend a valve’s service life.

Different valve types offer varying levels of durability. Here is a look at typical service life cycles:

| Valve Type | Typical Service Life (Cycles) |

|---|---|

| Universal Solenoid Valve | 1 million to 10 million |

| Universal Pilot Diaphragm Valve | 3 million to 7 million |

| Direct Acting Solenoid Valve | 1 million to 5 million |

| 2/2 Way Universal Solenoid Valve | 2 million to 8 million |

Choosing a valve with a high cycle rating ensures it can handle the demands of your application. This prevents premature failure. Always consider these durability ratings when making your selection. They help you choose a valve that will stand the test of time.

Future-Proofing Your Solenoid Valves for 2026

Planning for the future means looking beyond immediate needs. When choosing components like Solenoid Valves, consider their long-term impact on your operations. This forward-thinking approach helps you avoid costly surprises and ensures your systems remain efficient and adaptable.

Total Cost of Ownership vs. Initial Purchase Price

Many people focus only on the initial price of a valve. However, this is a common mistake. The initial purchase price of a solenoid valve typically accounts for only 10-15% of its total cost of ownership (TCO) over its operational lifespan. The remaining 85-90% of the TCO includes operational expenses. These expenses cover installation, maintenance, and energy consumption. They also include unplanned downtime, emergency repairs, and premature replacement. Prioritizing a low upfront cost can lead to total ownership costs reaching 3 to 5 times the initial purchase price. These hidden expenses add up quickly.

Energy Efficiency and Operational Costs

Energy consumption directly impacts your operational costs. Different valve technologies offer varying levels of efficiency.

- Dimension: Larger valves consume more energy. Optimal sizing is crucial.

- Design: Energy consumption varies significantly based on design:

- Normally Open/Normally Closed: The choice depends on the required open/closed cycle pattern for energy efficiency.

- Direct operated/Indirect operated: Indirect operated valves generally consume less energy. They do not require constant power to stay open.

- Cycle pattern: The frequency and duration of valve operation cycles affect energy consumption.

- Peak/Inrush current during opening: Solenoids require a higher peak current to open. Then, they need a reduced holding current. Overall consumption depends on how quickly current drops to the holding level.

- AC/DC power: DC solenoid valves typically consume more electricity than AC solenoid valves. However, DC can be made more efficient with additional circuitry.

- Additional circuitry: This can reduce overall energy consumption. It creates a temporary peak current during opening.

- Latching solenoid valve: This is excellent for energy saving. It helps when the valve needs to remain open for extended periods.

Energy-efficient solenoid valves incorporate innovative technologies. These include low-power circuits and latching mechanisms. They minimize energy consumption. Unlike traditional AC solenoid valves, which need a strong peak current to open, DC solenoid valves demand constant current. This leads to higher energy use. Latching solenoid valves use a permanent magnet to hold position. This eliminates continuous power needs. It reduces energy consumption by up to 95% after activation. Design choices like normally open/closed and direct/indirect operation also influence energy use. Indirect operated valves generally consume less energy. They do not require constant supply to remain open.

| Source | Energy Savings Percentage | Cost Reduction Implication |

|---|---|---|

| SBIR Project | 20-25% | Significant savings on energy bills, potential national savings of $400 to $500 million. |

| Kick and Drop Technology | Up to 80% | Lower energy consumption leads to significant reductions in operating costs. |

Advanced technologies like Kick and Drop mechanisms can reduce energy consumption by up to 80%. Some facilities report thousands of euros saved annually due to efficiency. The SBIR Project indicates potential national savings of $400 to $500 million for U.S. manufacturers.

Scalability and Adaptability of Solenoid Valves

Your system will likely evolve. Choose valves that can grow with your needs. Scalability means the ability to accommodate potential increases in flow rates or pressure. Flexibility means the capability to adapt to changing process requirements.

- Improved valve design: This incorporates optimized flow paths, reduced friction, and better sealing mechanisms. It enhances efficiency. This is a prerequisite for scalable performance.

- Electronic control systems: These allow for precise and responsive operation. They include adaptive control algorithms and real-time monitoring. This enables integration with evolving system needs.

- Multi-functional valve assemblies: These integrate multiple functions. They combine flow control and pressure regulation into a single unit. This simplifies system design. It also allows for easier modifications.

- Smart diagnostics and condition monitoring: This enables proactive maintenance and optimization. It provides data for adapting valve performance to changing conditions. It also prevents downtime during expansions.

Embracing Industry Trends and Technological Advancements

Staying current with industry trends helps you make smart choices for your systems. Technology changes quickly. What works today might not be the best solution tomorrow. For 2026, you should look at how new advancements can improve your operations.

The industry is moving towards smarter, more connected systems. Manufacturers now integrate IoT and smart technologies into valve designs. This enhances their functionality. It also drives market demand. You will see intelligent valves with built-in sensors and microprocessors. These provide real-time data. They also offer predictive maintenance. This means your system can tell you when it needs service before a problem happens.

Material science continues to improve. Engineers develop new materials to withstand extreme temperatures, pressures, and corrosive media. This makes valves more durable. Miniaturization is also a big trend. Smaller valves fit into compact applications. Think about medical devices and robotics. Coil design and power management also see innovations. These lead to enhanced energy efficiency.

Advanced manufacturing techniques like 3D printing are changing things. They allow for rapid prototyping and customized designs. This means you can get valves tailored exactly to your needs. Connectivity is also key. Industrial IoT (IIoT) and cloud integration allow valves to communicate. They integrate seamlessly into broader control networks. This helps create data-driven and autonomous operational environments.

You will also find more proportional control valves. These offer fine-tuned flow control. Low-power and ultra-low-power designs are becoming common. They save energy. Advanced materials like PEEK and PTFE offer better chemical resistance. Diagnostic features help with condition monitoring. Finally, modular and customizable valve platforms give you flexibility. These trends help you build more efficient and adaptable systems for the future.

Choosing Solenoid Valves requires a systematic approach. This careful method prevents operational inefficiencies and system failures. Informed decisions bring long-term benefits for 2026. They ensure your systems run smoothly and efficiently.

Proactive planning helps you avoid common pitfalls. It saves money and prevents downtime. Think ahead for reliable operations.

FAQ

What is the biggest mistake people make when choosing solenoid valves?

Many people only look at the initial purchase price. They forget about the total cost of ownership. This includes installation, energy use, and maintenance. A cheap valve can cost much more in the long run.

Why is material compatibility so important for solenoid valves?

The valve’s body and seals must match the fluid or gas it handles. Incompatible materials can corrode quickly. This causes leaks and system failures. Always check what the valve is made of.

How do "normally open" and "normally closed" valves differ?

A normally closed valve stays shut without power. It opens when power is applied. A normally open valve stays open without power. It closes when power is applied. Choose based on your system’s safety needs.

What are the advantages of using proportional control solenoid valves?

Proportional valves offer very precise control over flow or pressure. They do not just turn on or off. They can open to any position. This allows for fine adjustments and better process quality.