Selecting the correct material for Solenoid Valves is a critical decision in any industrial setting. Many engineers often debate brass vs steel solenoid valves. The optimal industrial solenoid valve material truly depends on your specific application’s requirements. For instance, when dealing with water, the choice between a stainless steel vs brass solenoid valve for water becomes very important. Different applications demand unique properties, and both brass and Steel Solenoid Valves offer distinct advantages.

Key Takeaways

- Choose brass valves for common uses like water and air. They cost less and work well in moderate conditions.

- Select stainless steel valves for harsh conditions. They handle strong chemicals, high heat, and high pressure.

- Always check the fluid type. Some fluids damage brass valves, but stainless steel resists many chemicals.

- Consider the total cost. Stainless steel costs more at first, but it lasts longer and needs less repair.

- Match the valve material to your industry rules. Some industries need special materials for safety and cleanliness.

Understanding Brass Solenoid Valves for Industrial Use

Brass Solenoid Valves are a common choice in many industrial settings. People often choose them for their balance of performance and cost. Brass, a material frequently chosen for solenoid valve manufacturing, is fundamentally an alloy composed of copper and zinc. The specific mechanical characteristics of brass, such as its toughness and ductility, are directly influenced by its alloy composition, particularly the proportion of zinc. A higher zinc content can enhance ductility but may concurrently diminish corrosion resistance, making careful consideration of the brass alloy composition crucial for optimal performance in various applications.

Advantages of Brass Solenoid Valves

Brass valves offer several benefits. They are generally more affordable than stainless steel options, which helps with budget planning. Brass is also easy to machine, making it versatile for different valve designs. It has good thermal conductivity, which can be useful in certain applications. These valves also resist corrosion well in many common environments, especially with water and air.

Limitations of Brass Solenoid Valves

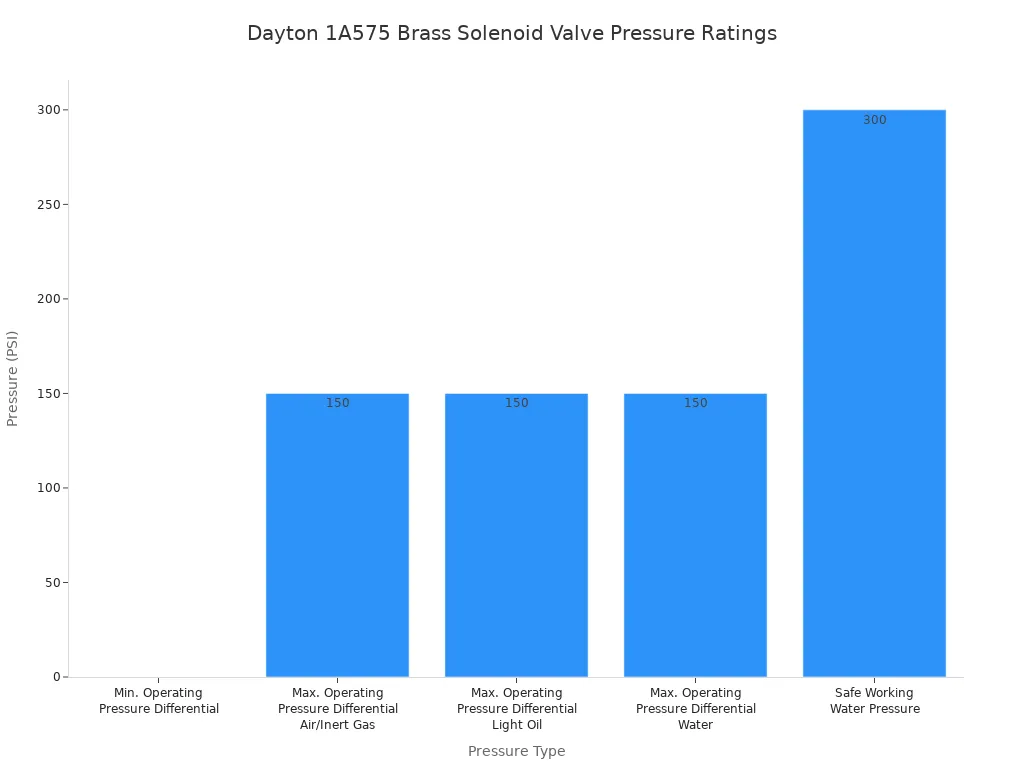

Despite their advantages, brass valves have some limitations. They are not suitable for all fluids. Strong acids, alkalis, or saltwater can corrode brass over time. Brass solenoid valves are ideal for low to medium-pressure and temperature applications. Exposing brass valves to high-temperature fluid applications increases their risk of premature failure due to deformation from elevated heat. Brass offers moderate temperature resistance, typically up to around 200°C (392°F). Pressure ratings also vary. For example, a 1-1/4″ 12V DC Electric Brass Solenoid Valve for water typically handles 0-90 PSI, and for air, it handles 7-90 PSI. Some models, like the Dayton 1A575 Normally Closed Brass Solenoid Valve, can manage up to 150 PSI for air, light oil, and water, with a safe working water pressure of 300 PSI.

| Valve Type | Pressure Type | Pressure (PSI) |

|---|---|---|

| Dayton 1A575 Normally Closed Brass Solenoid Valve | Min. Operating Pressure Differential | 0 |

| Dayton 1A575 Normally Closed Brass Solenoid Valve | Max. Operating Pressure Differential Air/Inert Gas | 150 |

| Dayton 1A575 Normally Closed Brass Solenoid Valve | Max. Operating Pressure Differential Light Oil | 150 |

| Dayton 1A575 Normally Closed Brass Solenoid Valve | Max. Operating Pressure Differential Water | 150 |

| Dayton 1A575 Normally Closed Brass Solenoid Valve | Safe Working Water Pressure | 300 |

Ideal Industrial Applications for Brass Solenoid Valves

Brass valves work well in many common industrial uses. They are often found in systems controlling water or air. You might see them in irrigation systems, pumps, and air compressors. They also appear in laundry and dry-cleaning equipment, industrial washing machines, and even coffee machines. Other applications include autoclaves/sterilizers, plastic molding machinery, and steam boilers.

Exploring Stainless Steel Solenoid Valves for Industrial Use

When applications demand more robust solutions, stainless steel solenoid valves often become the preferred choice. Stainless steel is an iron alloy that contains at least 10.5% chromium. This chromium content creates a passive layer on the surface, which gives stainless steel its famous corrosion resistance. Different grades of stainless steel, like 304 and 316, offer varying levels of resistance and strength.

Advantages of Stainless Steel Solenoid Valves

Stainless steel valves bring significant benefits to the table. They offer exceptional durability and can withstand high pressures and temperatures much better than brass. Their most notable advantage is superior corrosion resistance. For example, 316L stainless steel solenoid valves perform effectively in pipelines carrying acidic and chloride-rich media. They remain unreactive to various pharmaceutical and food-grade substances. The addition of molybdenum in 316L provides excellent resistance to atmospheric corrosion and high-temperature strength, making them suitable for marine environments and chemical processing. This low-carbon variant also shows great resistance to grain boundary corrosion and chloride corrosion.

Limitations of Stainless Steel Solenoid Valves

Despite their many strengths, stainless steel valves do have some drawbacks. The primary concern is cost. Steel is costly to machine and fabricate, and acquiring pure steel also adds to the expense. Its production processes are slower and consume more energy. This means the cost of a steel solenoid valve can be higher than a brass solenoid valve of the same size. Steel is tough, so it takes longer to fabricate to achieve the required precision and tolerance levels. While they offer superior performance, the initial investment for stainless steel solenoid valves is generally higher.

Ideal Industrial Applications for Stainless Steel Solenoid Valves

Stainless steel solenoid valves are essential in industries where aggressive media or extreme conditions are present. They are widely used in food processing, pharmaceutical manufacturing, and chemical processing. You will find them in water treatment plants, especially for pure water and aggressive media. Industrial processes handling steam, aggressive gases, dyes, and inks in the textile industry also rely on them. They effectively manage corrosive liquids like acetic acid, concentrated nitric acid, sodium hydroxide, and even abrasive liquids with particles. For corrosive gases such as chlorine and sulfur dioxide, or acidic vapors like hydrogen fluoride, stainless steel is the material of choice.

Direct Comparison: Brass vs. Stainless Steel Solenoid Valves

When choosing between brass and stainless steel for industrial applications, a direct comparison helps clarify which material best suits specific needs. Several factors come into play, including initial cost, long-term durability, and how each material reacts to different chemicals.

Cost Considerations for Solenoid Valves

Cost often plays a significant role in material selection. Generally, brass solenoid valves present a more budget-friendly option upfront. The raw material for brass is less expensive, and manufacturers find it easier to machine. This reduces production costs. In contrast, stainless steel is a more premium material. It costs more to acquire, and its toughness makes it harder and slower to machine. This increases manufacturing expenses.

Consider these approximate price ranges for different types of valves:

| Type of Solenoid Valve | Approximate Price (INR) |

|---|---|

| Industrial Solenoid Valve (Brass) | ₹400 – ₹1,200 |

| Stainless Steel Solenoid Valve | ₹1,500 – ₹3,000 |

While stainless steel has a higher initial price, businesses must also consider the total cost of ownership. This includes maintenance, potential downtime, and replacement frequency. A more durable valve might save money in the long run, even with a higher upfront cost.

Durability and Lifespan of Solenoid Valves

Durability directly impacts a valve’s lifespan and reliability in industrial settings. Stainless steel offers superior durability. It withstands high pressures and extreme temperatures much better than brass. Its inherent strength means it resists wear and tear, making it a robust choice for demanding environments. This resilience often translates into a longer operational life, reducing the need for frequent replacements.

Brass valves, while durable in their own right, perform best in moderate conditions. They are suitable for low to medium pressure and temperature applications. High heat can cause brass to deform over time, which shortens its lifespan. Therefore, for applications involving harsh physical conditions or extreme operational parameters, stainless steel typically provides a more reliable and longer-lasting solution.

Chemical Compatibility and Corrosion Resistance of Solenoid Valves

Chemical compatibility and corrosion resistance are critical factors, especially when valves handle various fluid media. Stainless steel excels in this area. Its chromium content creates a passive layer that provides excellent resistance to corrosion. Grades like 316L stainless steel are particularly effective against aggressive chemicals, acids, and chloride-rich media. They remain unreactive with many pharmaceutical and food-grade substances, making them ideal for sensitive applications.

Brass, however, has limitations regarding chemical compatibility. It performs well with water and air, but certain chemicals can cause significant degradation. Brass solenoid valves degrade due to dezincification. This process involves zinc leaching from the alloy. Exposure to acidic fluid media or alkaline water significantly accelerates this degradation. The brass loses structural integrity and weakens over time.

⚠️ Warning:

- Most acids cause brass valves to degrade quickly.

- Aggressive acid environments should be avoided for brass.

- Chlorinated environments are detrimental to brass.

Therefore, for applications involving strong acids, alkalis, saltwater, or other corrosive substances, stainless steel is the clear choice. Brass is best reserved for applications with benign media where its limitations will not compromise system integrity.

Temperature and Pressure Ratings for Solenoid Valves

Temperature and pressure ratings are crucial considerations when selecting Solenoid Valves for industrial applications. Each material handles these conditions differently. Brass valves generally operate well in moderate temperature ranges. For instance, many brass valves have a maximum operating temperature of 180 °F (82 °C). Other models can handle a maximum medium temperature of 100 °C (212 °F). Some brass valves also specify a maximum operating temperature of 149 °F, with a maximum process temperature of 176°F (80°C) when they use an NBR seal. These figures show brass is suitable for many common applications but has limits.

Stainless steel valves, on the other hand, offer much higher temperature and pressure capabilities. They maintain their structural integrity across a wide range of temperatures, from cryogenic applications to high-temperature steam regulation. This makes them ideal for demanding processes. Regarding pressure, stainless steel valves also perform exceptionally well. A 2-inch 110V AC stainless steel solenoid valve, for example, can handle a maximum operating pressure of 145 psi for both water and air (with a minimum of 7 PSI for air). Specifically, the SZW-50-110VAC model has an operating pressure range from 0 to 145 psi. Certain normally closed stainless steel solenoid valves with 1/4″ FPT ports and 24 Volt AC are rated for an operating pressure differential from 0 to 150 psi. These higher ratings make stainless steel the preferred choice for high-pressure systems.

Environmental Suitability of Solenoid Valves

The operating environment significantly influences the choice between brass and stainless steel. Brass valves are best suited for environments where they encounter benign media. However, certain environmental factors can accelerate corrosion in brass. Dezincification, a process where zinc leaches from brass, leads to a loss of structural integrity. This process speeds up when brass valves are exposed to acidic fluid media or alkaline water. Chemical exposure, moisture, and temperature extremes also contribute to corrosion. High temperatures increase reaction rates, and low temperatures can cause condensation, both of which contribute to corrosion. Galvanic corrosion also occurs when two different metals are in contact with an electrolyte, leading to accelerated corrosion of one metal.

Stainless steel valves thrive in harsh environments. Stainless steel, especially grades 304 and 316, offers exceptional corrosion resistance. Valves made from these steel grades resist media and environmental corrosion. They keep their surface strength and toughness even when exposed to harsh environments common in chemical processing facilities, seawater, and chemical processing pipelines. Stainless steel is compatible with multiple chemicals and industrial fluids. They effectively regulate fluids with different chemical properties. Stainless steel also has remarkable hygiene properties. It is easy to clean and sterilize, making it preferable for automated valves in hygiene-sensitive industrial applications like food processing and pharmaceutical industries. Steel valves are critical safety features for high-pressure and temperature fluid applications. They can accommodate a wide temperature range and high pressure without losing structural strength. For environments requiring watertight or corrosion-resistant properties, such as washdown areas, NEMA 4/4X rated stainless steel valves are ideal. NEMA 5 rated valves are suitable for dust-tight applications like dry powders or food processing dust.

Maintenance and Longevity of Solenoid Valves

Proper maintenance plays a key role in extending the longevity of any solenoid valve. For brass solenoid valves, a general guideline suggests performing maintenance when machinery is already being disassembled for servicing. You should examine the valve conveniently when other equipment is being serviced. Check the valve at regular intervals. The frequency depends on the application and past performance. Consider the safety risks if the valve fails. Evaluate the consequences of a valve failure at a critical time. Assess the cost of a valve failure, including lost productivity and repair/replacement expenses. Calculate the cost of servicing a valve, including time and resources. Applications that are particularly harsh on internal and external valve components will need more frequent attention.

Stainless steel valves generally require less frequent maintenance due to their superior durability and corrosion resistance. Their robust nature means they withstand demanding conditions for longer periods. This often translates into a longer operational life and reduced downtime. While the initial cost of stainless steel valves is higher, their extended lifespan and lower maintenance needs can lead to significant long-term savings. Regular inspections are still important for stainless steel valves to ensure optimal performance and to catch any potential issues early.

Key Factors for Selecting Solenoid Valve Material

Choosing the right material for your Solenoid Valves involves careful thought. Several key factors guide this decision. You need to look closely at what goes through the valve, where the valve sits, and how much money you want to spend over time.

Analyzing Fluid Media for Solenoid Valves

The fluid a valve handles is perhaps the most important factor. Different fluids have different properties. These properties directly affect which valve material works best. For example, toxic or very corrosive fluids, like strong acids or ammonia, need an isolation diaphragm or an all-stainless steel valve. This prevents leaks and stops the material from breaking down. Ammonia attacks copper, so brass or bronze valves are not suitable for ammonia service. Water-based fluids or those with corrosive additives often require stainless steel or special coatings. Standard brass or aluminum parts might corrode in these situations. Highly aggressive fluids might even need an isolation diaphragm valve to protect the metal parts.

Fluid viscosity also matters. If the fluid is very thick, or if oil thickens in cold conditions, you need a high-viscosity valve. These valves have larger clearances. Many valves work best with fluids up to about 50 cSt. Fluid temperature also plays a role. Both the fluid temperature and the surrounding air temperature affect valve selection. Seal materials and coil insulation must handle the operational temperature range. Standard NBR rubber seals work up to about 80°C. Higher temperatures, or very low temperatures, need materials like Viton (FKM) or silicone seals. For extreme temperatures, special high-temperature or low-temperature Solenoid Valves with appropriate coils or kits are necessary. This prevents coil burnout or seal failure.

| Component | Fluid Properties Dictating Selection |

|---|---|

| Material | Fluid Chemistry and Corrosiveness: Toxic or very corrosive fluids (e.g., acids, ammonia) need isolation diaphragm or all-stainless steel. Ammonia attacks copper, making brass/bronze unsuitable. Water-based fluids or those with corrosive additives require stainless steel or special coatings. Highly aggressive fluids may need an isolation diaphragm valve. Neutral fluids like hydraulic oil work with steel or cast iron, but special fluids like phosphate esters need specific seal materials (e.g., EPDM). |

| Fluid Viscosity: Very thick fluids or those in cold conditions need high-viscosity valves or ones with larger clearances. | |

| Fluid Temperature: Both fluid and ambient temperature impact selection. Seal materials and coil insulation must match the operational temperature range. Standard NBR seals work up to ~80°C; higher/lower temperatures need Viton (FKM) or silicone seals. Extreme temperatures require special high/low-temperature valves with appropriate coils or kits. |

Assessing Operating Environment for Solenoid Valves

The environment where you install the valve also influences your choice. This includes ambient temperature, humidity, and exposure to chemicals or dust. Brass solenoid valves have specific ambient temperature ranges. For regular operations with low viscosity fluid and an NBR Buna-N seal, they typically work between 15-125 °F (-10~50 °C). If you use an FKM/VITON seal for higher media temperatures, the ambient range remains similar, 15-125 °F (-10~50 °C). Some brass valves, like the SV6100A-Series, can handle a temperature range from -10 to 137°C (14 to 280°F). ASCO 551 Brass Valves are suitable for a temperature range of -40°C to +60°C. Stainless steel, however, generally performs better in harsher, more extreme environments, offering broader temperature and chemical resistance.

Evaluating Budget and Lifecycle Costs for Solenoid Valves

When you choose a valve, you must consider more than just the initial purchase price. While brass valves often cost less upfront, you should also think about the total lifecycle cost. This includes maintenance, potential downtime, and how often you might need to replace the valve. A more expensive stainless steel valve might last much longer and require less maintenance. This can save you money in the long run. Always balance the initial investment with the long-term operational expenses and reliability needs of your application.

Considering Regulatory Compliance for Solenoid Valves

Choosing the right valve material also means thinking about rules and regulations. Different industries have specific standards for the equipment they use. These rules ensure safety, quality, and environmental protection. You must pick a valve that meets these requirements for your specific application.

For example, when you use valves in drinking water systems, they need special approval. NSF61 approval is a key standard for these valves. This certification makes sure the valve materials do not release harmful substances into the water. It helps keep the water safe and clean. Manufacturers commonly use valves with NSF61 approval in drinking water systems, water dispensers, and other places where water touches people.

Other industries also have their own strict rules. The food and beverage industry, for instance, often requires materials that are easy to clean and do not react with food products. The pharmaceutical industry has similar demands for purity and non-contamination. Chemical processing plants deal with hazardous materials. They need valves that prevent leaks and resist corrosion from aggressive chemicals. Stainless steel often meets these higher standards better than brass. Its superior corrosion resistance and hygiene properties make it a preferred choice in regulated environments. Always check the specific regulations for your industry and application before making a final decision. This step helps avoid costly issues and ensures your system operates safely and legally.

Choosing the Right Solenoid Valve for Specific Industries

Choosing the correct valve material is crucial for operational success. Different industries have unique demands. Understanding these specific needs helps you select the best valve for the job.

Solenoid Valves in Food and Beverage

The food and beverage industry demands the highest hygiene standards. Valves must prevent contamination and be easy to clean. Manufacturers often use stainless steel valves in these settings. They resist corrosion and do not react with food products. For these applications, valves must meet strict regulatory requirements. They often need FDA approval and FDA certification. These certifications ensure the materials are safe for contact with consumables. This helps maintain product purity and consumer safety.

Solenoid Valves in Chemical Processing

Chemical processing environments are often harsh. They involve corrosive media, high temperatures, and sometimes hazardous conditions. Here, valve material selection is critical for safety and efficiency. ASCO valves are ideal for corrosive media. They use robust materials like PTFE, Stainless Steel, Polyetherimide (PEI), and Polyphenylene Sulphide (PPS). These materials offer exceptional resistance to acids, alkalis, and solvents. Designs with isolated media pathways, like Dry Armature, prevent chemicals from touching internal components. Media-separated valves with PTFE diaphragms also isolate the solenoid parts from aggressive liquids.

Consider these materials for corrosive applications:

| Material Type | Specific Materials | Key Characteristics for Corrosive Applications |

|---|---|---|

| Stainless Steel | 316 Stainless Steel | Resists corrosion and rust, good for acids and saline solutions. |

| Plastic Valves | PVDF (Polyvinylidene Fluoride) | Highly chemical-resistant, good for strong acids, bases, and solvents. |

| Alloys | Hastelloy | Designed for aggressive chemical environments, high temperatures, and pressures. |

| Coatings/Materials | Teflon (PTFE) Coated Valves | Highly resistant to corrosion and chemicals, especially aggressive acids. |

Gould specializes in stainless steel valves. They design these valves to withstand corrosive fluids, high temperatures, and hazardous operating environments. These valves offer reliability, safety, and leak-proof operation. They also provide rapid actuation. When selecting valves for highly corrosive chemical processing, avoid brass or aluminum in aggressive acid or chlorinated environments. Ensure the diaphragm quality is tested for chemical resistance. Verify the coil insulation can withstand the temperature range. For critical installations, consider fire-safe and high-pressure valve options to meet safety codes.

Solenoid Valves in Water Treatment

Water treatment plants handle various types of water, from raw to purified. They also use chemicals for purification. Valves must resist corrosion from water and treatment chemicals. Stainless steel is a popular choice for water treatment applications. It handles pure water and aggressive media well. Its durability and resistance to corrosion ensure long-term performance.

Solenoid Valves in Oil and Gas

The oil and gas industry presents unique challenges for valve selection. Engineers must choose materials that withstand extreme conditions and corrosive substances. Brass is often a good choice for valve bodies in fuel, oil, gas, and propane applications. It offers durability and resistance to corrosion in these specific media. However, for more aggressive media or high temperatures, stainless steel becomes essential. It resists harsh chemicals and maintains integrity under demanding conditions.

Seal materials are equally critical. NBR (Nitrile Rubber) commonly seals oils and fuels effectively. FKM (Viton) also works well for oil applications, especially when fluid temperature and viscosity change. For severe chemical resistance or high-heat situations, PTFE (Teflon) is the preferred material. It offers almost total insolubility and chemical inertness. Engineers must always match the seal material to the fluid type and the system’s pressure-temperature conditions. They also consider mechanical loading, cryogenic temperatures, and the chemical concentration of process media.

Solenoid Valves in HVAC and General Industrial Uses

HVAC systems and general industrial applications often rely on specific valve types. Brass valves are a common choice here. They control heating and cooling applications effectively. These valves regulate the flow of refrigerants and water, which helps heating and cooling operations run efficiently. For example, they manage refrigerant flow in air conditioning systems, directing it to the evaporator coil.

Brass valves also control fuel flow to furnaces. They open to allow gas when the temperature drops and close when the desired temperature is reached. This ensures precise temperature management. In general industrial settings, brass valves regulate water and air flow. Their balance of performance and cost makes them suitable for many everyday tasks. They offer reliable operation in environments that do not require the extreme resistance of stainless steel.

Selecting the appropriate Solenoid Valves material is paramount for operational efficiency, safety, and long-term cost-effectiveness. This choice directly impacts your system’s performance. Aligning material choice with the specific demands of your application ensures optimal performance and reliability. It helps avoid costly failures. For complex or critical applications, consulting with industry experts is recommended. They help you make an informed decision and ensure the best outcome.

FAQ

Why do people choose brass solenoid valves?

People often choose brass valves because they cost less upfront. They work well for common uses like water and air. Brass is also easy to shape, which helps with different valve designs. It offers good performance for many everyday tasks.

When should someone definitely use stainless steel solenoid valves?

You should use stainless steel valves for harsh conditions. This includes aggressive chemicals, very high temperatures, or high pressures. They also work best in food, beverage, and pharmaceutical industries. Stainless steel resists corrosion much better.

Can brass valves handle all types of fluids?

No, brass valves do not handle all fluids. Strong acids, alkalis, or saltwater can damage brass. It works best with benign media like water or air. For corrosive liquids, stainless steel is a safer choice.

Is stainless steel always more expensive than brass?

Stainless steel valves usually cost more to buy. The material itself is more expensive, and it takes longer to make. However, they often last longer and need less repair. This can save money over time.

How do temperature and pressure affect valve material choice?

Brass valves work well for moderate temperatures and pressures. High heat can deform brass. Stainless steel handles much higher temperatures and pressures. It keeps its strength in extreme conditions.