Chinese brass solenoid valves feature advanced manufacturing capabilities. They provide competitive pricing. Manufacturers demonstrate increasingly stringent quality control. A 2-way solenoid valve supplier from China often meets high standards. These valves offer significant advantages for diverse industrial applications. Many industrial users seek a reliable brass solenoid valve supplier. They also consider stainless steel solenoid valve options. Which China brass solenoid valve suppliers are reliable? This article explores top options for solenoid valves.

Key Takeaways

- Chinese solenoid valve makers use new technology. They make valves that save energy and last longer. They also add smart features for better control.

- Chinese solenoid valves are good value. They cost less but still work well. They meet global quality rules, like ISO 9001, which means they are reliable.

- When you pick a supplier, check their quality tests. Make sure they can make many valves. Also, see if they can change valves to fit your needs.

- Good communication helps when working with Chinese suppliers. Make sure they answer fast. Also, protect your ideas by registering them early in China.

The Evolving Landscape of Chinese Brass Solenoid Valve Manufacturing

Technological Advancements in Solenoid Valves

Chinese manufacturers actively push the boundaries of solenoid valve technology. They integrate smart features for remote control and monitoring. This provides real-time data and improves operational efficiency. Manufacturers also prioritize energy-efficient designs. These designs lower power consumption while maintaining high performance. Investment in new materials enhances durability and resistance to corrosion, leading to longer product lifespans.

Furthermore, the industry sees significant advancements in several key areas:

- Development of low-power valves supports battery-operated systems.

- Use of corrosion-resistant materials ensures functionality in harsh environments.

- Advances in electromagnetic actuation and sealing technologies enhance durability, response time, and adaptability.

- Integration of diagnostic sensors allows for predictive maintenance.

- Artificial intelligence (AI) and machine learning algorithms are integrated for performance monitoring and fault detection.

- A strong focus exists on energy-efficient and sustainable technologies, including materials with low environmental impact and extended lifecycle performance.

- Development of micro solenoid valves enables precision fluid regulation in fields like precision medicine and biomedical devices.

Cost-Effectiveness and Reliability of Chinese Solenoid Valves

Chinese brass solenoid valves offer a compelling combination of cost-effectiveness and reliability. Manufacturers have optimized production processes. This allows them to provide competitive pricing without compromising quality. Their commitment to continuous improvement ensures these valves perform consistently in various industrial applications. Businesses can achieve significant cost savings on procurement and maintenance. This makes Chinese suppliers an attractive option for global markets.

Meeting International Standards for Solenoid Valves

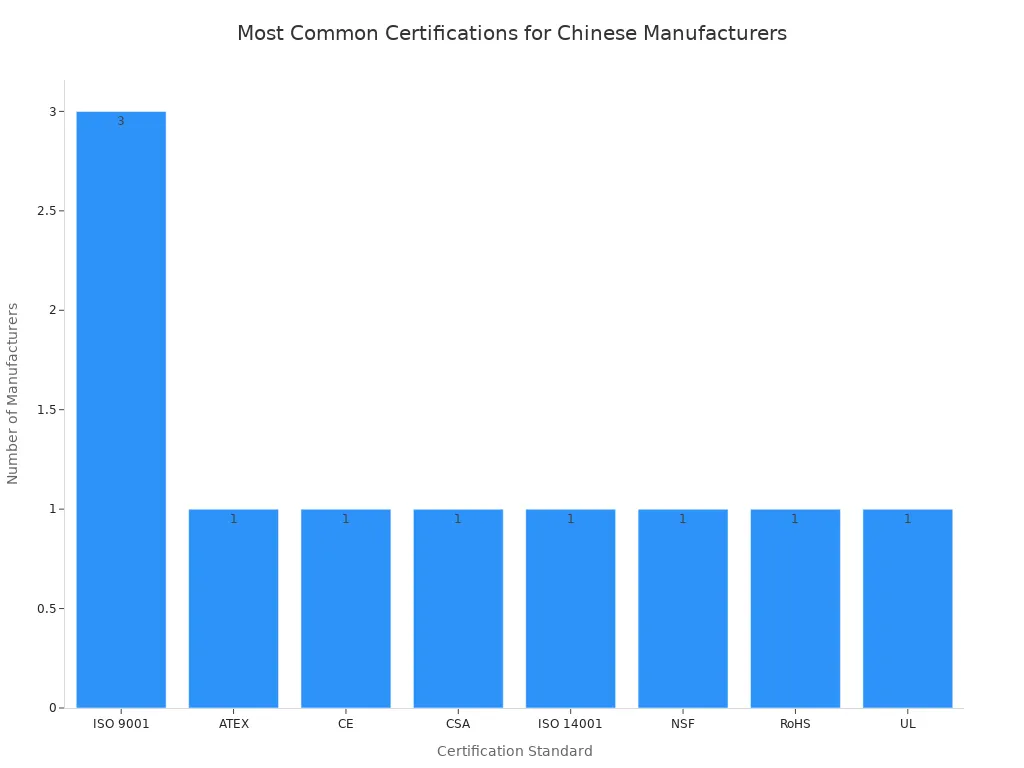

Chinese manufacturers increasingly meet stringent international quality standards. This commitment ensures their products are globally competitive and reliable. Many suppliers hold multiple certifications, demonstrating their adherence to global benchmarks.

| Manufacturer Type | Certifications |

|---|---|

| OEM Manufacturer | ISO 9001, CE |

| Custom Manufacturer | ISO 14001, RoHS |

| Export Manufacturer | CSA, UL |

| Domestic Manufacturer | ISO 9001, NSF |

| High-Volume Manufacturer | ISO 9001, ATEX |

ISO 9001 remains the most common certification among these manufacturers. Other important certifications include CE, UL, and ATEX. These certifications confirm product safety, quality management, and environmental responsibility.

This widespread adoption of international standards builds trust and facilitates global trade. It assures buyers of the quality and compliance of Chinese-made solenoid valves.

Key Criteria for Selecting Top Chinese Solenoid Valve Suppliers

Quality Assurance and Testing Protocols for Solenoid Valves

Selecting a top Chinese solenoid valve supplier requires careful evaluation of their quality assurance and testing protocols. Reputable manufacturers implement rigorous checks at every production stage. They ensure each product meets high performance and durability standards. Look for suppliers who hold various international certifications. These certifications demonstrate a commitment to quality and safety.

- ISO 9001:2015: This certification focuses on quality management systems, improving effectiveness and efficiency for customer satisfaction.

- ISO 14001:2015: This standard outlines environmental management system requirements for production sites.

- ISO 45001:2018: This international standard manages and controls workers’ safety and health.

- UL Certification: This component mark recognizes parts of a larger assembly, including coils approved for UL and CSA.

- CSA Certification: This component mark applies to products complying with United States Standards CSA C22.2 No. 139-13 for electrically operated valves.

- VDE Certification: This applies to electrical, electronic, and information technologies, including VDE certificated coils.

- NSF Certification: This applies to solenoid valve versions approved for alimentary fluid compatibility.

- PED Directive (2014/68/EU): This European Directive covers the design, manufacturing, inspection, and testing of pressure equipment.

- CRN (Canadian Registration Number): This is required for exporting pressure devices to Canada, indicating design acceptance and registration.

- REACH Regulation: This EU regulation protects human health and the environment from chemical risks.

- RoHS Directive (2011/65/UE): This European Directive restricts hazardous substances in electrical and electronic equipment.

- ATEX Certification: This applies to product lines and protective systems for use in potentially explosive atmospheres.

- EAC Certification (Eurasian Conformity): This indicates products conform to all technical regulations of the Eurasian Customs Union.

Production Capacity and Scalability for Solenoid Valves

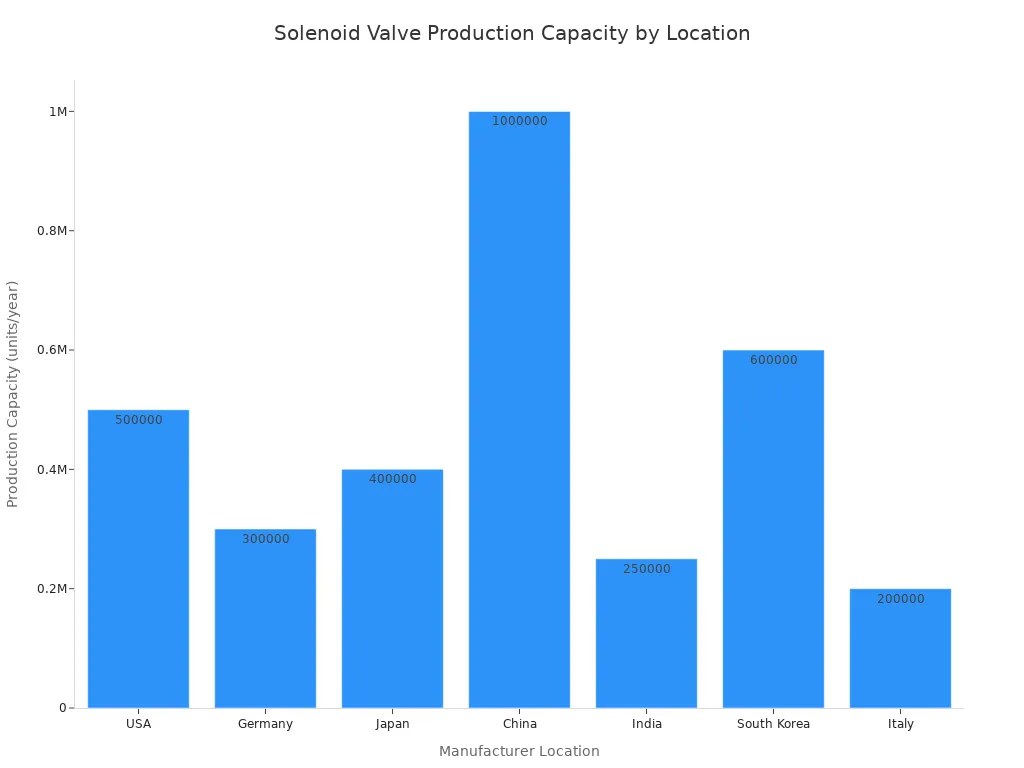

A supplier’s production capacity directly impacts their ability to fulfill orders efficiently. Top Chinese manufacturers boast impressive capabilities. They handle both small and large-scale demands. Factories with facilities measuring 2,500 m² or more typically handle medium to large orders efficiently. A team of 50 or more staff members indicates robust support for both research and development and production activities. Average response times under 4 hours suggest agile and efficient operational capabilities. China leads globally in solenoid valve production.

| Manufacturer Location | Production Capacity (units/year) |

|---|---|

| USA | 500,000 |

| Germany | 300,000 |

| Japan | 400,000 |

| China | 1,000,000 |

| India | 250,000 |

| South Korea | 600,000 |

| Italy | 200,000 |

This high capacity ensures consistent supply and shorter lead times for buyers.

Customization Capabilities and R&D Investment in Solenoid Valves

Leading Chinese suppliers understand diverse industrial needs. They offer extensive customization capabilities. This allows businesses to obtain valves perfectly suited for specific applications. These manufacturers invest significantly in research and development (R&D). This investment drives innovation. It also enables them to develop new materials, designs, and smart features. Their R&D efforts ensure they remain at the forefront of valve technology. They provide cutting-edge solutions to global markets.

Customer Service and After-Sales Support for Solenoid Valves

Effective customer service and robust after-sales support are crucial for any successful partnership. Top Chinese suppliers understand this necessity. They offer comprehensive support systems. These systems include responsive communication channels and dedicated technical assistance. Buyers can expect prompt answers to inquiries and expert guidance on product selection or troubleshooting. Many suppliers provide detailed warranties and readily available spare parts. This ensures minimal downtime and extends the operational life of the equipment. A strong commitment to customer satisfaction builds trust and fosters long-term business relationships.

Logistics and Supply Chain Efficiency for Solenoid Valves

Efficient logistics and a streamlined supply chain are vital for timely project completion. Chinese manufacturers excel in this area. They have developed sophisticated systems to manage inventory and shipping. This ensures products reach their destination quickly and reliably. Understanding typical lead times helps in planning procurement.

For normal models, the lead time is typically 1-3 days. Larger orders extend to approximately 10-15 days. Specific quantities also have clear delivery schedules:

| Quantity (pieces) | Lead time (days) |

|---|---|

| 1 – 2 | 8 |

| > 2 | To be negotiated |

This efficiency minimizes delays and reduces overall project costs. It allows businesses to maintain tight production schedules. Global shipping capabilities further enhance their appeal. They provide a seamless delivery experience for various industrial solenoid valves worldwide.

Top Chinese Brass Solenoid Valve Suppliers to Consider in 2025

Selecting the right supplier is crucial for sourcing high-quality brass solenoid valves. Several Chinese manufacturers stand out for their advanced technology, robust production capabilities, and commitment to international standards. Businesses should consider these top contenders in 2025.

Ningbo SENYA Pneumatic Technology Co., Ltd. for Solenoid Valves

Ningbo SENYA Pneumatic Technology Co., Ltd. specializes in engineering and manufacturing solenoid valves and pneumatic components. They possess strong research and development capabilities. Their advanced production facilities allow them to develop both standard and customized solutions for demanding industrial requirements. SENYA implements a rigorous quality system. This system includes 30 quality inspections and performance tests. These checks ensure product reliability.

SENYA offers over 40 solenoid valve models. These models cover media temperatures from −40°C to 220°C. They also handle operating pressures from 0 to 50 bar. The company provides flexible customization options:

- Waterproofing: IP65/IP67/IP68 is available for most models (excluding USF series).

- Seal Materials: FKM, EDPM, HNBR, FFKM, PTFE suit different media compatibility.

- Body Materials: Brass, stainless steel, or engineering plastics are available.

- Manual Override: An optional manual knob allows forced opening without power.

- Mounting Method: Bottom mounting, horizontal mounting, and flexible mounting are customizable.

- Valve Manifold Design: Customizable designs are available.

SENYA’s product range includes various types of solenoid valves. These include 2/2-way solenoid valves, 2/2-way pneumatic valves, and 2/2-way pulse solenoid valves. They also offer 2/2-way stainless steel solenoid valves and 2/2-way brass solenoid valves. Their offerings extend to 5/2-way directional valves and 3/2-way solenoid valves.

The company manufactures a diverse array of products. These include solenoid valves, pneumatic cylinders, and pneumatic push-in fittings. They also produce water valves and air treatment units. Specific products like DMF-Dd Durst-Free Right Angle Solenoid Valves and Frls High Quality Nice Price Pneumatic Air Treatment Units are part of their portfolio.

SENYA’s product line features specific models:

| Model | Type | Port Size | Fluid Temperature | Operating Pressure | Media |

|---|---|---|---|---|---|

| Brass 2/2-Way 2W-W Series | Direct Acting, NC | 1/8″–2″ | -5°C to 80°C (120℃ opt.) | 0–1.0MPa | air, water, oil, gas |

| Brass 2/2-Way VX2120 Series | Direct Acting, NC | 1″–4″ (flanged) | -5°C to 80°C (120℃ opt.) | 0–1.0MPa | air, water, oil, gas |

| Brass 3/2-Way KSD Series | Direct Acting, NC | 1/8″–3/8″ | -5°C to 80°C (-5°C to 120℃) | 0–1.0MPa | air, water, oil, gas |

| Aluminum 5/2-Way V4 Series | Pilot Operated | 1/8″–1/2″ (M5) | -20°C to 80°C | 0.15–0.8MPa | air |

| Aluminum 5/2-Way M4 Series | Pilot Operated | 1/8″–1/2″ (M5) | -20°C to 80°C | 0.15–0.8MPa | air |

Ningbo SENYA Pneumatic Technology Co., Ltd. has achieved ISO9001:2008 international quality system certification. They also hold several other important certifications. These include CE, SGS, QMS, and CTB231229044CX-ZS CE ROHS certification. These credentials demonstrate their commitment to high manufacturing standards and product safety.

Wuxi Xinming Auto-Control Valves Industry Co., Ltd. for Solenoid Valves

Wuxi Xinming Auto-Control Valves Industry Co., Ltd. serves a wide array of primary markets. Their products find application in diverse sectors. These include petroleum, chemical, metallurgy, and power industries. They also cater to environmental protection, architecture, food, and gas sectors. Their valves are crucial for scientific research.

The company has a global reach. They serve markets across North America, South America, Western Europe, and Eastern Europe. Their presence extends to Eastern Asia, Southeast Asia, the Middle East, Africa, and Oceania. They operate worldwide. Specific countries where their products are widely used include India, the United States, Brazil, Pakistan, Nigeria, and Bangladesh. They also serve Russia, Mexico, Japan, the Philippines, Ethiopia, Egypt, Vietnam, Germany, France, and Italy.

GUANLONG Valve Manufacturing Co., Ltd. for Brass Valves

GUANLONG Valve Manufacturing Co., Ltd. stands as a notable supplier focusing on brass valves. They have established a reputation for producing reliable and durable brass valve solutions. Their expertise in brass manufacturing ensures high-quality products suitable for various industrial and commercial applications. GUANLONG’s commitment to material integrity and precision engineering makes them a strong choice for businesses seeking specialized brass valve components.

China Valves Technology (Changsha) Co. Ltd. for Industrial Solenoid Valves

China Valves Technology (Changsha) Co. Ltd. stands as a significant player in the industrial valve sector. They specialize in designing and manufacturing a broad range of industrial valves. Their products serve critical applications across various heavy industries. These industries include power generation, petrochemicals, metallurgy, and water treatment. The company focuses on producing high-performance valves that withstand demanding operational conditions. They emphasize robust construction and reliable functionality. This commitment ensures their valves meet the stringent requirements of industrial clients.

Suzhou Neway Valve Co., Ltd. for Diverse Valve Solutions

Suzhou Neway Valve Co., Ltd. offers a comprehensive portfolio of valve solutions. They provide more than just solenoid valves. Their extensive product line caters to a wide array of industrial needs. Customers can find:

- Gate valves

- Ball valves

- Globe valves

- Check valves

- Butterfly valves

- Control valves

- Safety valves

- Nuclear valves

Neway Valve demonstrates a strong commitment to innovation. They possess a technical team comprising over 60 professionals. This team drives their research and development efforts. The company holds several technical patents. They also make significant annual investments in developing new products and materials. This dedication ensures they remain at the forefront of valve technology. Their diverse offerings and innovative approach make them a versatile partner for various industrial projects.

Maximizing Your Partnership with Chinese Solenoid Valve Suppliers

Effective Communication Strategies for Solenoid Valve Procurement

Successful partnerships with Chinese suppliers depend heavily on clear communication. Businesses must establish clear communication channels early in the procurement process. This proactive approach prevents misunderstandings and streamlines operations. Prioritizing suppliers with fast response times, such as those responding within three hours, ensures quick issue resolution. This responsiveness minimizes delays and maintains project timelines. Effective communication builds trust and fosters a collaborative environment, essential for long-term success.

Quality Control at Every Stage for Solenoid Valves

Implementing robust quality control measures is paramount when sourcing from Chinese manufacturers. Buyers should identify and assess the factory’s quality system. This includes facilitating sample drawing, where factories organize products for inspectors to draw samples evenly from different production periods. Smooth communication among the customer, inspection company, and factory is crucial for resolving issues effectively. Final inspection checks include verifying cleanliness, dryness, and correct part locations. Nameplate and painting inspections also ensure compliance. Buyers must outline inspection requirements in the purchase order, stating that the entire order requires a “PASS” result from an appointed inspection agent before shipment. This holds suppliers accountable. Buyers should also set expectations for failed inspections, outlining steps for suppliers to resolve quality issues. Clarifying the role of third-party inspectors, who report on quality, is important. Holding suppliers accountable for re-inspection fees incentivizes them to meet quality standards.

Navigating Contracts and Intellectual Property for Solenoid Valves

Protecting intellectual property (IP) is a critical concern when collaborating with Chinese manufacturers. China operates on a “first-to-file” system for trademarks and patents. This means the first applicant secures rights, regardless of original ownership. Trademark hijacking and trade secret theft are common risks. Companies must include proper IP protection clauses in all contracts and agreements. They should also implement dedicated IP management, including active monitoring for infringement. Early registration of trademarks and patents in China is essential. Despite enforcement difficulties, administrative enforcement through IP authorities or customs can be effective. Civil litigation in specialized IP courts also offers a path for dispute resolution.

Choosing the right Chinese brass solenoid valve supplier in 2025 offers a significant strategic advantage. Businesses can leverage their advanced manufacturing capabilities and benefit from highly competitive pricing. These suppliers also demonstrate a strong commitment to stringent quality control. They provide reliable and efficient solenoid valve solutions for diverse industrial applications. They are indeed your best bet for meeting demanding operational requirements.

FAQ

What quality certifications do Chinese solenoid valve manufacturers typically hold?

Many Chinese manufacturers hold ISO 9001, CE, and RoHS certifications. Some also possess UL, CSA, ATEX, and NSF. These certifications demonstrate adherence to international quality and safety standards. Buyers can trust products from certified suppliers.

How do Chinese solenoid valve suppliers ensure product reliability?

Suppliers implement rigorous quality control at every production stage. They conduct extensive testing and inspections. Many factories use advanced equipment for performance checks. This commitment ensures consistent product reliability and durability for industrial applications.

Can Chinese manufacturers customize solenoid valves for specific needs?

Yes, leading Chinese manufacturers offer extensive customization capabilities. They invest in research and development to meet diverse industrial requirements. This includes variations in materials, sizes, and operational specifications. Businesses can obtain valves tailored to their unique applications.

What are the typical lead times for solenoid valve orders from China?

Lead times vary by order size and model. Normal models often ship within 1-3 days. Larger orders typically require 10-15 days. Specific quantities have clear delivery schedules. This efficiency helps maintain project timelines.

How can buyers protect intellectual property when working with Chinese suppliers?

Buyers should include strong IP protection clauses in all contracts. Registering trademarks and patents in China early is crucial. Active monitoring for infringement is also recommended. This proactive approach helps safeguard intellectual property rights.