A 2/2 Ways Solenoid Valve is an electrically controlled device. It expertly manages media flow. This valve either allows substances to pass or completely blocks them. Essentially, it functions as a reliable on/off flow control device in various systems. Understanding what is a 2/2 way solenoid valve helps many engineers. They also need to know how does a 2/2 way solenoid valve work. Its 2/2 solenoid valve working principle is quite simple. You might find a 2/2 normally open solenoid valve in some setups. It is also important to know which solenoid valve is normally closed for different applications. Both types are essential.

Key Takeaways

- A 2/2 Ways Solenoid Valve controls fluid flow. It has two ports and two positions. It acts like an on/off switch for liquids or gases.

- These valves work using electromagnetism. An electric current creates a magnetic field. This field moves a plunger to open or close the valve.

- There are two main types: normally closed (NC) and normally open (NO). NC valves block flow without power. NO valves allow flow without power.

- These valves offer quick response and remote control. They are useful in many areas. These include industrial processes, HVAC, and medical equipment.

What is a 2/2 Ways Solenoid Valve?

A 2/2 Ways Solenoid Valve is a simple yet powerful device. It controls the flow of liquids or gases. Think of it as an electrical switch for fluids. When you activate it, the valve either opens to let fluid through or closes to stop it. This basic function makes it very useful in many different systems.

Two Ports and Two Positions Explained

The name "2/2 Ways" tells you a lot about how this valve works. It has two ports. One port is for the fluid to enter, and the other is for it to exit. These are often called the inlet port and the outlet port. They act as the entry and exit points for the fluid, like compressed air. This setup allows for basic control over the fluid’s movement.

The "two positions" part means the valve can be in one of two states. It is either fully open or fully closed. When open, fluid flows freely from the inlet to the outlet. When closed, the valve completely blocks the flow. This simple open or closed action helps start or stop the flow of gases or liquids.

Valve bodies come in various materials. Manufacturers often use durable options like brass, stainless steel, or plastic. You might also find bodies made from nylon (Polyamide – PA) or PVC (PolyVinylChloride). For standard applications, copper alloy is a common choice. However, for specific uses, like in the food industry, you can request materials such as SS304 and SS316. Forged brass is another popular material option.

These valves also handle different pressures. A typical 2/2 Ways Solenoid Valve might have a maximum pressure differential of 300 psig and a minimum pressure differential of 5 psi. Some suppliers do not offer valves for extremely high pressures, such as 2000 PSI (about 14 Mpa). However, specialized high-pressure 2/2-way solenoid valves can operate in a wide range, from 0.00 bar up to 160.00 bar.

On/Off Functionality of 2/2 Ways Solenoid Valve

The core job of a 2/2 Ways Solenoid Valve is its on/off functionality. It acts like a gate. When the valve is "on," the gate opens, and fluid passes through. When it is "off," the gate closes, and no fluid can pass. This makes it perfect for applications where you need to start or stop a process quickly and reliably.

For example, in an irrigation system, the valve turns on to water plants and turns off when watering is complete. In industrial settings, it might control the flow of chemicals or air to machinery. This straightforward control makes the 2/2-way solenoid valve a fundamental component in many automated systems. Its ability to simply open or close a pathway is its greatest strength.

Working Principle of a 2/2 Ways Solenoid Valve

Understanding how a 2/2 Ways Solenoid Valve works helps you appreciate its role in controlling fluid flow. These valves rely on electromagnetism to perform their on/off function. They achieve this through two main types of mechanisms: direct-acting and pilot-operated.

Electromagnetic Operation of the Solenoid Coil

The heart of any solenoid valve is its coil. This coil uses electricity to create a magnetic force. When an electric current passes through the solenoid coil, it creates an electromagnetic field. This is similar to how a simple electromagnet works.

Here is how this process unfolds:

- Electric current passing through the coil produces a magnetic field.

- This magnetic field moves through the plunger, forcing the core to move upwards against a spring.

- The plunger is positioned in the coil’s center because this is where the electromagnetic field lines are most compact and strongest.

- This movement unlocks the orifice, opening the valve.

- Pressurized gas or liquid then flows through the opened valve.

The solenoid acts as an electromagnetic coil. It converts electrical energy into a linear mechanical force. When electric current flows through the coiled copper wire, it generates a magnetic field. This electromagnetic force then attracts or repels a magnetic plunger. The plunger’s movement creates the mechanical action to open or close the valve. This fundamental principle of electromagnetism allows precise switching of the valve between open and closed states using electrical signals. A sufficient electromagnetic field typically generates within 5 to 50 milliseconds, ensuring quick response for precise control.

Direct Acting 2/2 Ways Solenoid Valve Mechanism

A direct-acting 2/2 Ways Solenoid Valve is straightforward in its operation. The solenoid’s power directly moves the plunger. This plunger then opens or closes the valve. This direct action controls the flow of the substance passing through the valve body.

Key components in this mechanism include:

- Solenoid coil: An electric current sent through this coil creates a magnetic field.

- Plunger or armature: The magnetic field generated by the solenoid coil moves this component.

- Valve body: This structure allows the substance to flow. The plunger’s movement opens or closes the flow within it.

Direct-acting valves offer several advantages. They are suitable for negative pressure circuits. They also handle particle debris well. You can find them in cost-effective compact sizes. Manufacturers offer them in 2/2 and 3/2 way normally open or normally closed versions. Miniature versions are even available for very high pressures.

Pilot Operated 2/2 Ways Solenoid Valve Mechanism

Pilot-operated solenoid valves work differently from direct-acting ones. Direct-acting valves use the solenoid’s force to directly open or close the main valve. This converts electrical energy into mechanical energy. They are simple but need significant power, especially for larger openings.

Pilot-operated valves are useful when fluid pressures are high and orifice diameters are large. In these cases, the solenoid alone may not have enough force. These valves use the pressurized fluid itself to actuate the main valve. The solenoid acts as a ‘pilot’ to direct this fluid.

Here is a quick comparison:

| Type | Operation Mechanism | Power Requirement | Common Use Cases |

|---|---|---|---|

| Direct-acting | Coil pushes/pulls a shaft to shift valve | Full power | Quick response systems, precise fluid control |

| Pilot-operated | Fluid pressure opens the valve | Lower power | Larger systems, cost-efficient solutions |

In pilot-operated valves, the solenoid controls small pilot orifices. These orifices manage fluid pressure in a top cavity. This pressure then positions a diaphragm or piston. When energized, the solenoid expels fluid from the top cavity. This creates a pressure difference. The pressure difference then opens the main valve.

Pilot-operated solenoids generally consume less energy than direct-acting ones. However, they need enough fluid pressure to operate. They are also more likely to clog from impurities. Direct-acting valves typically operate within 5 to 10 milliseconds. Pilot-operated valves are slower, with response times from 15 to 150 milliseconds, depending on their size.

Normally Closed vs. Normally Open 2/2 Ways Solenoid Valve

When choosing a solenoid valve, you often encounter two main types: normally closed (NC) and normally open (NO). These terms describe the valve’s default state when it receives no power. Understanding this difference is crucial for proper system design and operation.

Normally Closed (NC) 2/2 Ways Solenoid Valve Operation

A normally closed solenoid valve is in a closed state when it is de-energized. This means it blocks flow in its default, unpowered condition. For a Normally Closed (N.C.) 2/2 Ways Solenoid Valve, when there is no electrical current, a spring holds the plunger in a position that keeps the valve closed, thereby blocking the flow of the medium. Its default resting position prevents the flow of liquid or gas. In this de-energized state, no electric current flows through the coil, and the armature rests against the valve seat, effectively blocking the flow.

People often choose normally closed solenoid valves when the opening time is short or when the valve does not open and close frequently. They are energy-saving because they remain closed most of the time and only require power for short durations when opening is necessary. These valves are ideal for scenarios requiring frequent closure, such as emergency shutdowns. Gas pipelines also use them, needing automatic shut-off during power outages or faults to prevent danger. They serve as protective valves in industrial equipment, ensuring fluid disconnection during critical events.

Normally Open (NO) 2/2 Ways Solenoid Valve Operation

In contrast, a normally open (NO) solenoid valve is in an open state when it is de-energized. This means fluid flows freely through it by default, without any power. When you apply electrical current to the coil, it creates a magnetic field. This field then pulls the plunger, moving it to close the valve and stop the flow. People use normally open valves in systems where the fluid needs to flow most of the time. They are also useful in applications where a power failure should not interrupt the flow.

Basic Structure of a 2/2 Ways Solenoid Valve

A 2/2 Ways Solenoid Valve has several key parts. Each part works together to control fluid flow. Understanding these components helps you see how the valve operates.

Solenoid Coil and Plunger Assembly

The solenoid coil is the electrical part of the valve. It creates a magnetic field when electricity flows through it. Inside the coil sits the plunger assembly. This assembly includes a fixed core and a movable core, also called the plunger. These cores are often made from rustproof, corrosion-resistant materials. They have high magnetic conductivity. The guide tube, which holds the plunger, can be brass or stainless steel. The spring, usually made of rustproof SUS304 stainless steel, helps return the plunger to its original position. Seals, like NBR or FKM, and shading rings, made of copper or silver, also form part of this assembly.

Valve Body, Ports, and Orifice

The valve body is the main housing. It contains all the internal parts. It also has two ports: an inlet and an outlet. These ports allow fluid to enter and exit the valve. A common port size is 1/4 inch. However, you can find many other sizes. For example, some valves offer port sizes ranging from 3/8 inch up to 2 inches. Inside the valve body, an orifice is a small opening. The plunger moves to either block or unblock this orifice, controlling the fluid path.

Seal and Spring Mechanism

Seals are crucial for preventing leaks. They ensure the valve closes tightly and fluid only flows when it should. Different seal materials suit different applications. For instance, NBR seals offer good resistance to oil products and solvents. FKM (Viton) seals handle a wide range of chemicals and higher temperatures. EPDM seals work well with water, steam, and acids. PTFE (Teflon) seals resist almost all fluids and can handle higher pressures and temperatures. The spring mechanism helps the valve return to its default position, whether normally closed or normally open, when the coil is de-energized.

Common Applications of 2/2 Ways Solenoid Valve

These versatile valves play a crucial role in many different industries. They offer reliable on/off control for various fluids. You will find them in systems that need precise management of liquids and gases.

Fluid Control in Industrial Processes

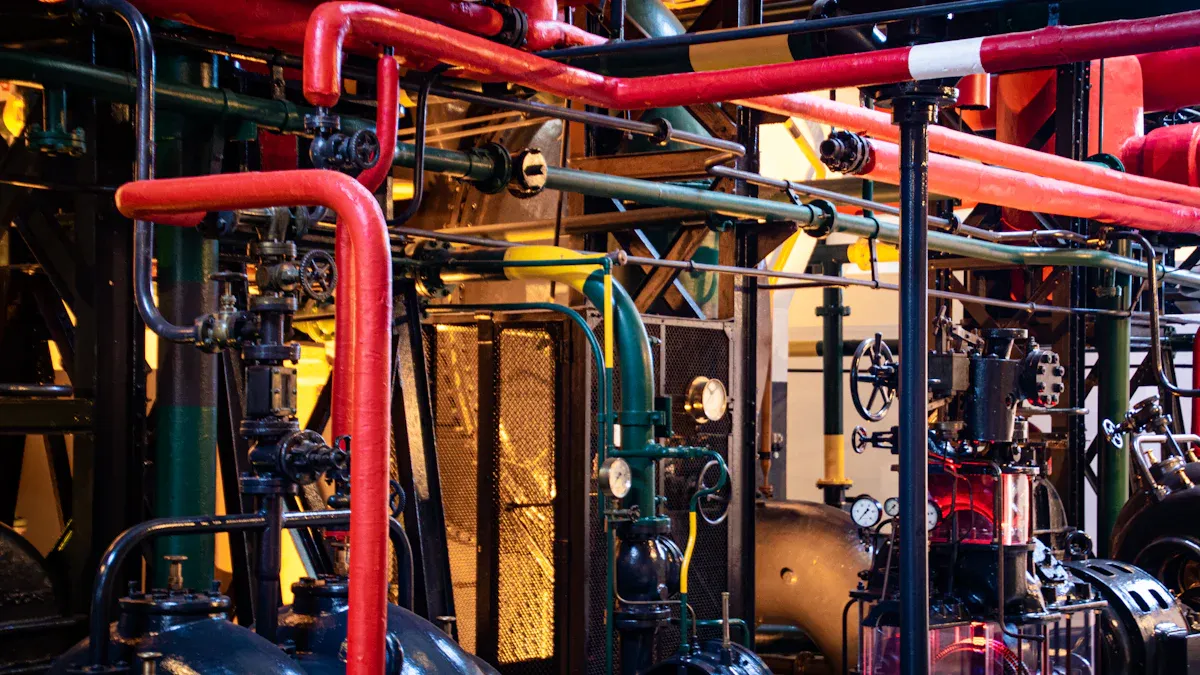

Industrial settings heavily rely on these valves for fluid control. They are essential for:

- Industrial automation

- Process control

- Manufacturing environments

These valves ensure precise release of fluids or gases. This is vital for many industrial processes. They also optimize distribution, making systems more efficient. This ensures equal and controlled fluid distribution. Furthermore, they facilitate accurate dosing and mixing of substances. This guarantees consistency in operations across diverse industrial processes.

You can find them in:

- Laundry and dry-cleaning equipment

- Industrial washing equipment

- Autoclaves/sterilizers

- Compressors and vacuum pumps

- Plastic molding machinery

- Steam boilers

- Food processing machinery

- Sprinklers and fire fighting systems

- Dentist equipment

- Coffee machines

- Boilers

These valves handle high flow rates and very high pressures. For example, some industrial solenoid valves manage pressures up to 370 psi (2550 kPa). Manufacturers like HydraForce offer flow rates from 0 to over 189 liters per minute. Bosch Rexroth provides valves with flow rates from 1.5 to 260 liters per minute.

HVAC and Refrigeration Systems

In HVAC systems, these valves are crucial for temperature regulation. They control the flow of refrigerant or natural gas to a furnace. They operate with reliable on/off control. They open the gas line when they receive an electrical signal. They close it when the signal stops. This ensures both safety and efficiency in managing gas flow for heating or cooling purposes.

Automotive and Irrigation Applications

You also find these valves in automotive systems. They manage fuel, oil, or air flow for various engine functions. For instance, they control vacuum lines or fuel vapor recovery systems. In irrigation, they automate watering schedules. They open to allow water to flow to sprinklers or drip lines. Then they close to stop the flow. This helps conserve water and ensures plants receive the right amount of hydration.

Medical Equipment and Automation

Solenoid valves are truly essential in medical and dentistry fields. They precisely start and stop the flow of liquids or gases as equipment requires. This makes them vital for many critical functions. For example, they control fluids in diagnostic devices, surgical tools, and dental chairs. Their reliability ensures patient safety and accurate operation.

Medical equipment places very specific demands on these valves. Manufacturers design them to control corrosive or high-purity fluids without compromise. A compact design is also crucial for saving space inside complex medical devices. Furthermore, these valves often feature zero dead volume. This prevents cross-contamination, which is extremely important in healthcare settings. They are available in a large range of tubing sizes. This helps meet various flow and pressure needs for different medical applications. Many designs also include a removable and rotatable coil. This makes service and installation much easier for technicians.

These specialized features allow medical devices to function with high precision and hygiene. From controlling oxygen flow in ventilators to managing reagents in lab analyzers, these valves perform critical tasks. They help automate processes, reducing human error and improving efficiency in hospitals and clinics. Their ability to deliver precise, repeatable actions makes them indispensable for modern healthcare technology.

Advantages of Using a 2/2 Ways Solenoid Valve

These valves offer many benefits across various systems. Their design and operation make them a popular choice for fluid control.

Rapid Response and Compact Design

Solenoid valves react very quickly. They can open or close almost instantly when they receive an electrical signal. This rapid response is crucial in applications needing precise timing, like automated manufacturing lines or emergency shut-off systems. Their compact size also makes them easy to integrate into tight spaces. Engineers appreciate their small footprint, especially in complex machinery or portable equipment. This design efficiency helps save valuable space and simplifies system layouts.

Remote Control and Energy Efficiency

You can control these valves from a distance. This remote operation allows automation and reduces the need for manual intervention. Operators can manage fluid flow from a central control room, improving safety and efficiency. These valves also offer good energy efficiency, especially when designed for specific applications. Consider the energy consumption for different valve types in an automated irrigation system:

| Valve Type | Energy to Open (Wh) | Energy to Close (Wh) | Energy in Open Position (Wh) | Total Daily Consumption (Wh) |

|---|---|---|---|---|

| Valve A | 0.05 | 0.05 | 0.05 | 0.15 |

| Valve B | 0.03 | 0.03 | 0.03 | 0.09 |

These figures show how different valves consume energy. Valve A and Valve B operate once a day for 30 minutes in an irrigation system. The ‘Energy in Open Position’ accounts for that half-hour of operation. The ‘Total daily consumption’ for each valve combines the energy used for opening, closing, and staying open. These values represent typical usage. They include both the initial power to open and the holding power to keep the valve open, averaged for overall daily energy consumption. This efficiency helps reduce operational costs over time.

Distinguishing 2/2 Ways Solenoid Valve from Other Types

Solenoid valves come in many forms. Each type serves a specific purpose. Understanding the differences helps you choose the right valve for your needs. We often compare the simple 2/2 valve to more complex ones.

Comparison with 3/2 Way Solenoid Valves

A 3/2 way solenoid valve works differently from a 2/2 valve. It has three ports and two positions. This allows it to do more than just turn flow on or off. It can direct fluid to two different paths. Think of it as a switch that can send fluid one way or another.

Here is a quick look at how they differ:

| Feature | 2/2 Way Solenoid Valve | 3/2 Way Solenoid Valve |

|---|---|---|

| Number of Ports | 2 (inlet, outlet) | 3 (inlet, outlet, common) |

| Function | On/off control | Directs flow in two paths |

| Complexity | Simpler design | More complex design |

The internal parts also show these differences.

2/2 Way Solenoid Valve Internal Structure:

- Solenoid Coil: Produces a magnetic field when charged.

- Plunger or Spool: A movable part connected to the solenoid coil.

- Valve Body: Houses internal components.

- Inlet and Outlet Ports: Points for fluid entry and exit.

3/2 Way Solenoid Valve Internal Structure:

- Solenoid Coil: Produces a magnetic field when charged.

- Plunger or Spool: Moves within the valve body, controlled by the solenoid coil.

- Valve Body: Contains the internal parts.

- Inlet, Outlet, and Common Ports: Points for fluid entry, exit, and distribution.

The extra port on a 3/2 valve gives it more control options. It can switch between two different lines.

Comparison with 5/2 Way Solenoid Valves

A 5/2 way solenoid valve is even more complex. It has five ports and two positions. People often use these valves to control double-acting pneumatic cylinders. These cylinders need air to push them in both directions. The 5/2 valve directs air to one side of the cylinder while venting air from the other side. This allows precise movement. A 2/2 valve simply opens or closes a single path. A 5/2 valve manages two separate air lines for more advanced control.

This blog explored the 2/2 Ways Solenoid Valve, a fundamental component for precise on/off fluid control. Its simple design and reliable operation make it essential in various automated systems. You learned about its two ports and two positions, along with its direct-acting and pilot-operated mechanisms. This valve offers rapid response, remote control, and energy efficiency. Its versatility makes it indispensable across many industries, including HVAC, automotive, and medical fields. It truly stands as a cornerstone of modern fluid management.

FAQ

What does "2/2 Ways" mean for a solenoid valve?

"2/2 Ways" means the valve has two ports and two positions. Fluid enters one port and exits the other. The valve can be either fully open, allowing flow, or fully closed, blocking it. This provides simple on/off control.

How do normally closed and normally open 2/2 valves differ?

A normally closed (NC) valve blocks flow when it has no power. It opens when you apply electricity. A normally open (NO) valve allows flow when it has no power. It closes when you apply electricity.

What are common materials for 2/2 solenoid valve bodies?

Manufacturers often use durable materials like brass, stainless steel, or plastic for valve bodies. You might also find options such as nylon or PVC. For specific uses, like in the food industry, SS304 and SS316 are common choices.

How fast can a 2/2 solenoid valve open or close?

Direct-acting 2/2 solenoid valves respond very quickly. They typically operate within 5 to 10 milliseconds. Pilot-operated valves are a bit slower. Their response times range from 15 to 150 milliseconds, depending on their size.