.jpg)

For corrosive applications in 2025, a stainless steel solenoid valve typically leads the way. Many engineers wonder, “What materials are best for corrosive fluids?” Plastic solenoid valves offer specialized solutions. They handle specific chemical compatibilities very well. However, brass solenoid valves are generally unsuitable for corrosive media. They often fail quickly. Understanding “What are the common types of solenoid valves?” helps in making the right choice. A reputable solenoid valve manufacturer, perhaps from a leading China solenoid valve factory, ensures quality in these critical components.

Key Takeaways

- Stainless steel solenoid valves are the best choice for most corrosive liquids. They resist rust and work well in high heat and pressure.

- Plastic solenoid valves are good for very specific, strong chemicals that even stainless steel cannot handle. But they do not work well with high heat or pressure.

- Never use brass solenoid valves with corrosive chemicals. They break down quickly and can cause problems.

- Always check what your fluid is made of and how hot or pressurized it will be. This helps you pick the right valve material.

- Choosing the right valve material saves money in the long run. It prevents frequent repairs and keeps your system working.

Stainless Steel Solenoid Valves: The Top Choice for Corrosive Media

Unmatched Corrosion Resistance

Stainless steel stands out for its incredible ability to resist corrosion. A passive layer of chromium oxide forms on its surface. This layer acts as a shield. It protects the metal from harsh chemicals. Different grades of stainless steel offer varying levels of resistance. For example, 316L stainless steel contains molybdenum. This addition significantly boosts its resistance to pitting and crevice corrosion. It performs exceptionally well in environments with chlorides, like saltwater or certain acids. Industries often choose stainless steel for handling strong acids, alkalis, and other aggressive fluids.

High Pressure and Temperature Capabilities

Stainless steel possesses inherent strength. This strength allows it to handle extreme operating conditions. It withstands high pressures without deforming or failing. This makes it a reliable choice for demanding industrial processes. Furthermore, stainless steel maintains its structural integrity at elevated temperatures. It does not soften or degrade easily when exposed to heat. This thermal stability is crucial for applications involving hot corrosive media. Other materials, like plastics, often cannot endure such high pressures and temperatures.

Durability and Longevity of Stainless Steel Solenoid Valves

The robust nature of stainless steel contributes to the long lifespan of these components. They resist wear and tear from continuous operation. They also stand up to erosion caused by flowing corrosive fluids. This durability translates into reduced maintenance needs and lower replacement costs over time. Businesses rely on stainless steel Solenoid Valve components for their consistent performance. Their longevity ensures system reliability in critical applications. High-quality manufacturing processes further enhance this inherent durability. A well-chosen stainless steel Solenoid Valve provides peace of mind.

Ideal Corrosive Applications

Stainless steel solenoid valves excel in many challenging environments. They are the go-to choice for industries dealing with aggressive chemicals. Engineers often specify them for critical processes where reliability is paramount.

- Chemical Processing Plants: These facilities handle a wide array of corrosive substances. Stainless steel valves manage strong acids, alkalis, and various organic compounds. They ensure safe and efficient control of these dangerous fluids.

- Pharmaceutical Manufacturing: The pharmaceutical industry demands high purity and resistance to harsh cleaning agents. Stainless steel meets these strict requirements. It prevents contamination and withstands sterilization processes.

- Food and Beverage Production: Here, hygiene is crucial. Stainless steel resists corrosion from cleaning solutions and food acids. It also prevents bacterial growth, making it ideal for processing and packaging lines.

- Water Treatment Facilities: These plants often deal with chlorinated water, ozone, and other chemicals used for purification. Stainless steel valves maintain integrity against these corrosive elements, ensuring clean water delivery.

- Oil and Gas Industry: Offshore platforms and refineries expose equipment to saltwater, crude oil, and various chemicals. Stainless steel offers robust protection against these corrosive mixtures, preventing leaks and system failures.

- Marine Applications: Ships and marine equipment constantly face saltwater exposure. Stainless steel components, including the Solenoid Valve, resist rust and degradation in this highly corrosive environment.

These applications highlight stainless steel’s versatility and strength. It consistently delivers reliable performance where other materials would quickly fail.

Plastic Solenoid Valves: Specialized Chemical Resistance

Superior Chemical Compatibility

Plastic solenoid valves offer unique advantages for specific corrosive applications. They excel where metals, even stainless steel, might struggle. Certain chemicals, like strong acids or bases, can attack metal alloys. Plastics, however, often remain inert to these substances. This makes them an excellent choice for highly aggressive media. They prevent contamination and ensure the purity of the fluid. When you need to handle very specific or unusual chemicals, plastic valves often provide the best solution.

Material Types for Plastic Solenoid Valves

The effectiveness of a plastic valve depends heavily on its material. Different plastics offer varying levels of chemical resistance and physical properties. Manufacturers select these materials carefully for valve bodies, seals, and diaphragms. Here is a look at some common types:

| Material | Common Use | Key Properties |

|---|---|---|

| PTFE (Polytetrafluoroethylene) | Diaphragms and flange gaskets for severe chemical resistance | Almost totally insoluble, high temperature resistance, chemically inert |

| EPDM (Ethylene Propylene Terpolymer) | Standard seat material | Excellent resistance to acids, alkalis, salts up to 90°C; not suitable for oils, petrochemicals, concentrated acids |

| NBR (Nitrile Rubber) | Oil and petroleum applications | High chemical resistance to oils and petroleum, excellent abrasion resistance; weak on oxidizing media |

| FKM/FFKM (Fluorinated Elastomer/Perfluoro Elastomer) | Seals for high temperatures | More chemical and temperature resistance than NBR/neoprene; some FFKM grades perform above 200°C |

| PPS (Polyphenyl Sulphide) | Valve body material | Performs above 200°C, resistant to acids, alkalis, and abrasion |

| PVDF (Polyvinylidene Fluoride) | Valve bodies in acid & solvent applications | Flexible, resistant to solvents, acids, bases; not suitable for high temperature resistance |

| PEEK (Polyether Ether Ketone) | Valve body material | Excellent mechanical and chemical properties; susceptible to high concentrations of sulfuric and nitric acid |

Each material has its strengths. For example, PTFE is almost universally chemically resistant. PVDF is great for many acids and solvents. Choosing the right plastic ensures the Solenoid Valve performs reliably.

Pressure and Temperature Limitations

While plastic valves offer excellent chemical resistance, they do have limitations. They generally cannot withstand the same high pressures and temperatures as stainless steel. Plastics can soften or deform at elevated temperatures. This can lead to leaks or valve failure. High pressures can also cause plastic components to crack or burst. Therefore, engineers must carefully consider the operating conditions. If your application involves extreme heat or pressure, a plastic valve might not be the best fit. Always check the manufacturer’s specifications for pressure and temperature ratings.

Niche Corrosive Applications for Plastic Solenoid Valves

Plastic valves truly shine in specific situations where their unique properties are indispensable. They handle environments that would quickly degrade even the toughest metals. For instance, in water treatment and management, plastic valves are crucial. They resist the corrosive effects of chlorinated water and meet strict EPA drinking water standards. This makes them perfect for purifying drinking water and managing wastewater systems.

💡 Tip: Always check the chemical compatibility chart for your specific fluid before selecting any valve material.

The chemical processing industry also relies heavily on plastic valves. Their non-reactive nature allows them to withstand potent chemicals, harsh acids, bases, and other aggressive substances. These valves ensure safe and efficient operation within chemical manufacturing systems. You will also find them in aquariums and aquaculture. Here, they manage water flow, oxygenation, treatment, and filtration. They resist saltwater and biological materials, helping maintain healthy aquatic environments.

In the food and beverage industry, manufacturers choose plastic valves for their non-toxic and easy-to-clean properties. These features are essential for maintaining sanitary conditions. They are vital in processes from dispensing flavors to brewing beer. Finally, plastic valves offer natural insulation in electrical systems. This minimizes electrical interference and prevents heat transfer. This benefit is particularly useful in automotive and medical products, where precise control and safety are paramount. These specialized applications show the critical role plastic valves play.

Why Brass Solenoid Valves Fail in Corrosive Environments

Susceptibility to Chemical Attack

Brass is an alloy. It mainly consists of copper and zinc. These metals react poorly with many corrosive substances. When brass comes into contact with certain chemicals, it quickly degrades. Chlorides and acidic environments cause rapid degradation. Solenoid valves in industrial applications often encounter corrosive chemicals, acids, or contaminants. These substances lead to degradation. This chemical attack weakens the brass structure. It makes the valve unreliable.

Material Degradation Risks

The chemical attack on brass leads to specific material degradation. One common issue is dezincification. This process removes zinc from the brass alloy. It leaves behind a porous, weakened copper structure. This weakened material cannot withstand normal operating pressures. It becomes brittle and prone to cracking. Dezincification also creates pathways for leaks. These leaks can cause system failures. They also pose safety hazards. The valve’s internal components, like springs and seals, also suffer. They lose their integrity.

Limited Chemical Compatibility of Brass Solenoid Valves

Brass has very limited chemical compatibility. It cannot handle many common corrosive media. For example, strong acids, alkalis, and even some common industrial fluids quickly corrode brass. This makes brass unsuitable for most chemical processing. It also fails in water treatment applications with chlorine. Engineers must carefully check chemical compatibility charts. They will find brass is often listed as incompatible. Using brass in these environments guarantees early failure. This leads to costly repairs and downtime.

When Brass Solenoid Valves are Acceptable

While brass valves generally do not perform well with corrosive media, they still have their place. You can use them effectively in specific non-aggressive fluid services. For example, brass valves are suitable for pipelines that handle regular water. They also work well with non-acidic fluids. These applications do not involve harsh chemicals that would quickly degrade the brass.

Brass valves are ideal for low to medium-pressure and temperature applications. They perform reliably when conditions are not extreme. If your system does not involve high heat or intense pressure, brass can be a cost-effective choice. They also work well in environments with high moisture content. This makes them useful in places where humidity is a factor but corrosive chemicals are absent.

Brass offers good thermal and electrical conductivity. This property makes it beneficial for applications needing precise temperature control. Think about HVAC systems or solar water heating systems. In these setups, brass valves can help manage fluid flow efficiently. They contribute to maintaining desired temperatures without the risk of chemical attack.

💡 Note: Always confirm the fluid’s exact composition and operating conditions. This ensures brass is truly compatible before installation.

So, while you should avoid brass for corrosive tasks, it remains a viable option for many common, less demanding fluid control needs. It offers a practical solution when the media is benign and operating parameters are moderate.

Comparing Solenoid Valve Materials for Corrosive Use

Choosing the right material for a Solenoid Valve in corrosive applications is a critical decision. It directly impacts system reliability and safety. Different materials offer distinct advantages and disadvantages. Understanding these differences helps engineers make informed choices.

Key Material Properties

Each material brings a unique set of properties to the table. These properties dictate how a valve performs in harsh environments.

- Stainless Steel: This material offers exceptional strength and rigidity. It maintains its structural integrity under high pressure and temperature. Its passive chromium oxide layer provides excellent corrosion resistance. This layer makes it highly durable.

- Plastics (e.g., PTFE, PVDF, PEEK): Plastics are generally lighter and more flexible than metals. They excel in chemical inertness against specific aggressive media. However, they typically have lower mechanical strength and thermal resistance. Their properties vary significantly between different plastic types.

- Brass: Brass is a copper alloy. It offers good machinability and moderate strength. It conducts heat and electricity well. However, its primary weakness in corrosive applications is its susceptibility to chemical attack, particularly dezincification.

Chemical Compatibility Chart for Solenoid Valves

Selecting the correct material requires careful consideration of the fluid’s chemical composition. A chemical compatibility chart is an indispensable tool for this process. It provides detailed information on how various materials react with different chemicals.

💡 Tip: A comprehensive chemical compatibility chart for common Solenoid Valve materials is available from resources like Solenoid-Valve.World. They offer a downloadable chemical resistance chart. This chart details hundreds of chemicals. It also shows their compatibility with various valve materials. This serves as a valuable reference for fluid control system design and upgrades. This resource also includes a detailed chemical compatibility guide. It assists in selecting appropriate valve body and seal materials.

Consulting such a chart helps prevent costly mistakes. It ensures the chosen valve material will not degrade or contaminate the media. It also helps avoid system failure.

Performance Metrics Comparison

When evaluating materials for corrosive applications, several performance metrics come into play. These metrics help determine the best fit for specific operating conditions.

| Metric | Stainless Steel | Plastics (e.g., PTFE, PVDF) | Brass |

|---|---|---|---|

| Corrosion Resistance | Excellent (especially 316L) | Excellent for specific chemicals; highly material-dependent | Poor for most corrosive media; susceptible to dezincification |

| Pressure Capability | High | Low to moderate | Moderate |

| Temperature Capability | High | Low to moderate; material-dependent | Moderate |

| Durability/Lifespan | Very High; long service life | Moderate; can be brittle or degrade with UV/heat | Low in corrosive environments; prone to failure |

| Cost | Moderate to High | Low to Moderate | Low |

| Chemical Inertness | Good for a wide range of chemicals | Excellent for specific, highly aggressive chemicals | Poor for many common chemicals |

| Mechanical Strength | High | Low to moderate | Moderate |

Stainless steel consistently offers superior performance across most metrics for corrosive applications. Plastics provide specialized resistance for niche chemical challenges. Brass, while cost-effective, generally falls short in corrosive environments. Engineers must weigh these factors carefully. They need to balance performance requirements with budget constraints.

Cost vs. Lifespan Analysis of Solenoid Valves

When you choose a valve for corrosive applications, the initial price tag often catches your eye. However, smart buyers look beyond that first cost. They consider the total cost of ownership. This includes the initial purchase, installation, maintenance, and potential replacement over the valve’s entire working life. A cheaper valve upfront might end up costing you much more in the long run.

Let’s look at how different materials stack up in terms of initial cost:

| Material | Initial Cost |

|---|---|

| Plastic Valves | Most Economical |

| Brass Valves | Moderate |

| Stainless Steel | Highest |

You can see that plastic valves usually offer the most economical starting point. They provide a cost-effective solution for projects with tight budgets. However, in tough settings, their limited durability might lead to higher long-term costs. Brass valves sit in the middle. They offer a more budget-friendly option, balancing cost with decent performance for less demanding jobs. Stainless steel valves have the highest initial cost. This is because they offer superior corrosion resistance. But this investment often pays off in industries that demand reliability and low maintenance.

Think about it this way: stainless steel is the most expensive material among the options. However, its incredible durability means it lasts a very long time. This reduces how often you need to replace it. It also cuts down on maintenance. This makes the overall cost much lower over the years. You might pay more at first, but you save money by avoiding frequent repairs and downtime.

Plastic valves, while cheap to buy, might not last as long in harsh conditions. They can become brittle or degrade with UV exposure or heat. This means you might replace them more often. Each replacement adds to your total cost. It also causes interruptions in your operations.

Brass valves present a tricky situation. Their moderate initial cost seems appealing. But in corrosive environments, they fail quickly. This leads to constant replacements. Each failure means more money spent on new parts and labor. It also means lost productivity. So, a brass valve that seems affordable at first can become a very expensive problem.

💡 Tip: Always calculate the total cost of ownership. This includes initial purchase, installation, maintenance, and expected replacement costs over the system’s lifespan. This approach helps you make the most economical decision.

Ultimately, balancing initial cost with expected lifespan and performance is key. For corrosive applications, investing in a higher-quality material like stainless steel often proves to be the most cost-effective choice in the long run. It ensures reliability, reduces maintenance, and prevents costly system failures.

Essential Factors for Solenoid Valve Selection

Choosing the right valve for your system involves more than just picking a material. Several critical factors guide this decision. Considering these elements ensures your system runs efficiently and safely.

Media Compatibility Assessment

First, you must understand the fluid your valve will control. This is called media compatibility. Different fluids have different properties. For example, air, water, oil, or steam all behave differently. Their viscosity and chemical makeup directly affect the valve’s material and design. Corrosive fluids need materials like stainless steel or special plastics. Neutral fluids, like water or air, work with more materials, including brass or aluminum. The valve’s parts, including the body and seals, must be compatible with the fluid. This prevents corrosion and ensures long-term operation.

- Medium Type: Identify the specific fluid the valve will control. This ensures you pick the right material and prevent early failure.

- Material Selection: Choosing the correct valve material is vital for performance.

- Brass: Good for water and air. It offers a cost-effective choice.

- Stainless Steel: Best for corrosive environments or chemicals.

- Plastic: Lightweight and resists some corrosive media. It is not ideal for high-pressure systems. Match the material to the fluid and environment to avoid early wear.

Operating Conditions: Temperature and Pressure

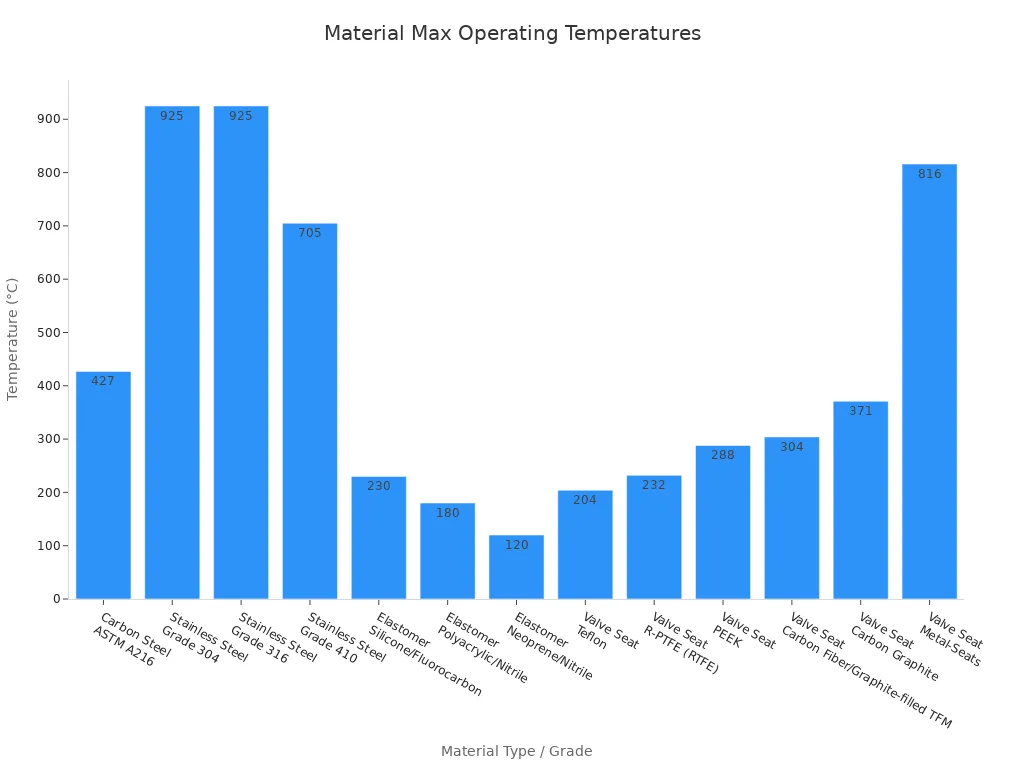

Operating conditions play a huge role in valve selection. High temperatures and pressures demand specific materials. Metals become weaker when temperatures rise. This means pressure ratings decrease as temperature increases. You need specialized designs and materials for high-temperature and high-pressure applications. There are big differences in ratings between high and low-temperature situations.

| Material Type | Specific Material/Grade | Maximum Continuous Operating Temperature |

|---|---|---|

| Carbon Steel | ASTM A216 (Grades WCA, WCB, WCC) | 800°F (427°C) |

| Stainless Steel | Grade 304 | 1,700°F (925°C) |

| Stainless Steel | Grade 316 | 1,700°F (925°C) |

| Stainless Steel | Grade 410 | 1,300°F (705°C) |

| Elastomer | Silicone and Fluorocarbon | Exceeds 400°F (230°C) |

| Elastomer | Polyacrylic and Hydrogenated Nitrile | 320-350°F (160-180°C) |

| Elastomer | Neoprene and Nitrile | 210-250°F (100-120°C) |

| Valve Seat Material | Teflon | 400°F (204°C) |

| Valve Seat Material | R-PTFE (RTFE) | 450°F (232°C) |

| Valve Seat Material | PEEK | 550°F (288°C) |

| Valve Seat Material | High-Temperature Carbon Fiber / Graphite-filled TFM (PTFE) | 580°F (304°C) |

| Valve Seat Material | Carbon Graphite | 700°F (371°C) |

| Valve Seat Material | Metal-Seats | Greater than 750°F (399°C) up to 1,500°F (816°C) |

| Valve Trim Components | Inconel 718, 17-4 stainless steel, Nitronic 50 | Elevated temperatures (for high yield strength and torsional stiffness) |

Brass works for non-aggressive fluids like water in pipelines. It suits low to medium pressure and temperature. Steel, however, is better for harsh fluids, like in chemical plants. It offers superior resistance and strength for higher temperatures and pressures.

Flow Rate and Solenoid Valve Sizing

Correctly sizing your valve is crucial for efficient operation. It ensures you get the right amount of fluid flow.

- Understand Your Flow Requirements: Identify the media type (e.g., compressed air, water, steam). Determine the needed flow rate (L/min or m³/h). Note the working pressure. Also, consider system variables like pipe direction and distance from the source.

- Utilize Flow Charts and Datasheets with Cv and Kv Ratings: Manufacturers provide detailed flow charts and datasheets. These include Cv (flow coefficient) and Kv (flow factor) ratings. These ratings help match the desired flow rate and pressure drop to the correct valve size.

- Differentiate Sizing Logic for Direct-Acting vs. Pilot-Operated Valves:

- Direct-acting valves: Sizing mainly depends on port size. They work even with no pressure difference. They suit low-pressure or vacuum systems.

- Pilot-operated valves: These need a minimum pressure difference (usually 0.5 bar or more) to work. They offer higher flow capacity in smaller sizes. They are ideal for high-pressure or large-volume applications. For low-pressure or gravity-fed systems, consider a larger size or use a direct-acting valve.

Environmental Considerations

The environment where a valve operates greatly affects its performance. It also impacts how long the valve lasts. For example, harsh or corrosive environments demand materials that resist those conditions. Factors like temperature, humidity, and other environmental elements can change how a valve works. This makes it essential to pick a valve right for its specific operating conditions.

Harsh environmental conditions significantly influence the choice of valve material. These conditions include saltwater, chemicals, or extreme weather. Imagine a valve used outdoors. Prolonged exposure to sunlight can cause plastic valves to break down from UV rays. This means you need UV-stabilized materials for those valves. High humidity can lead to corrosion in some metals. Dust and debris can clog moving parts. Always consider the valve’s surroundings. This ensures it works reliably and safely.

Regulatory and Safety Standards for Solenoid Valves

Choosing valves for corrosive service also means following important rules. Many regulatory and safety standards apply to these valves. These standards ensure the valves are safe and work correctly.

- National Fire Protection Association (NFPA): This group sets standards for valves in dangerous places. They include rules for materials and how to install them.

- International Electrotechnical Commission (IEC): This commission creates global standards for valves, especially for hazardous uses.

- UL Certification (Underwriters Laboratories): This certification shows a valve meets safety rules for North America.

- CE Marking/ATEX Certification: These are needed for valves in the European Union. They mean the valve is safe for explosive environments and flammable substances.

- CSA Certification (Canadian Standards Association): This applies to valves for Canada and some hazardous uses in the US.

- IECEx Certification: This is an international certification for hazardous uses worldwide.

- NEMA Rating (National Electrical Manufacturers Association): This rating tells you which environments are suitable for a valve’s electrical parts. It shows protection against things like moisture and dust.

- IP Ratings (Ingress Protection): These ratings define how well a valve protects against solid objects and liquids. They are very important for resisting corrosive media and dangerous environments.

These standards help ensure valves are safe and reliable. They protect both equipment and people.

Future Outlook for Corrosive Solenoid Valves in 2025

The world of corrosive fluid handling constantly evolves. Manufacturers push boundaries to create even more resilient and intelligent valve solutions. What can we expect in 2025 and beyond for valves in harsh environments? We see exciting developments in materials and smart technology.

Advancements in Stainless Steel Alloys

Stainless steel remains a cornerstone for corrosive applications. However, innovation does not stop there. Researchers develop new stainless steel alloys with enhanced properties. These alloys offer even greater resistance to specific aggressive chemicals. They also withstand higher temperatures and pressures. Expect to see more widespread use of super duplex stainless steels. These materials provide superior strength and corrosion resistance in extremely harsh conditions. New surface treatments and coatings also emerge. They further extend the lifespan of stainless steel components. These advancements mean even more reliable performance in the toughest industrial settings.

Innovations in Plastic Solenoid Valve Materials

Plastic valves are also seeing significant breakthroughs. Engineers create advanced polymers and composite materials. These new plastics overcome some traditional limitations. They offer improved temperature and pressure ratings. They also provide broader chemical compatibility. For example, new fluoropolymers resist an even wider range of highly aggressive acids and solvents. These innovations make plastic valves viable for applications previously reserved for metals. They also offer lighter weight and often lower cost solutions for specialized needs. This means more options for handling unique corrosive media.

Smart Solenoid Valve Technology Integration

The future of corrosive valves is not just about materials; it is also about intelligence. Smart technology integrates into valve designs. This brings unprecedented levels of control and safety. AI-driven predictive maintenance systems analyze data from valves. They anticipate failures and schedule timely repairs. This prevents costly downtime. Advances in smart manufacturing lead to more intelligent and interconnected valve designs. Miniaturization of valve components enables their use in smaller, more precise applications. Think about wearable medical devices or intricate chemical dosing systems.

Smart sensors and advanced control systems enhance valve performance. Position feedback systems, like limit switches or IoT sensors, monitor real-time valve status. They trigger safety alerts when conditions exceed limits. These systems are vital for strengthening safety in hazardous fluid applications. They integrate with emergency shutdown systems. This automatically stops processes during elevated hazards. Valves with diagnostic and self-testing capabilities detect issues. They generate timely alerts. This allows operators to proactively rectify problems. It maintains system reliability and prevents hazard propagation, such as leakages. Ongoing research explores new materials and energy-efficient designs. This enhances valve performance and sustainability.

Sustainable Material Choices for Solenoid Valves

The push for sustainability is changing how manufacturers make things. This includes valves. Companies now focus on reducing their environmental impact. They look for materials that are better for the planet. This means using fewer new resources and creating less waste.

Manufacturers are now using recycled metals. They put recycled brass, stainless steel, and aluminum into valve bodies. This helps reduce the need for new metal production. It saves energy and cuts down on mining. This is a big step towards greener manufacturing.

💡 Tip: Choosing valves made from recycled materials helps lower your carbon footprint.

Plastic alternatives are also becoming popular. Traditional plastics come from oil. Now, companies are finding new options. These new plastics are either recyclable or biodegradable. This means they can be reused or break down naturally. This helps reduce plastic waste in landfills. These innovations make plastic valves a more eco-friendly choice for certain applications.

Finally, sustainable coatings are making a difference. Manufacturers use non-toxic coatings and sealants. These improve how long products last. They do this without harming the environment. These coatings protect the valves. They also prevent dangerous chemicals from getting into the air or water. This focus on sustainable materials shows a commitment to a healthier planet. It also ensures that valves perform well for a long time.

Stainless steel valves remain the top recommendation for harsh corrosive environments. They offer unmatched durability. Plastic valves are crucial for specific chemical resistance where stainless steel may not be suitable. They handle unique media well. Always avoid brass valves for any corrosive media; they will cause system failure. Instead, prioritize thorough media compatibility and operating condition analysis. This ensures you select the optimal valve for your needs.

FAQ

What is the best solenoid valve material for corrosive applications?

Stainless steel solenoid valves are generally the top choice. They offer excellent corrosion resistance and handle high pressures and temperatures. For specific, highly aggressive chemicals, plastic solenoid valves provide superior chemical compatibility.

Can I use brass solenoid valves with corrosive chemicals?

No, you should avoid brass solenoid valves for corrosive chemicals. Brass is susceptible to chemical attack and dezincification. This leads to rapid material degradation and system failure.

Why do people use plastic solenoid valves if they have temperature and pressure limits?

Plastic solenoid valves offer superior chemical compatibility for specific, highly aggressive chemicals. These chemicals might even attack stainless steel. They are ideal for niche applications where chemical resistance is more critical than high pressure or temperature capabilities.

How do I choose the right solenoid valve for my specific fluid?

First, assess your media compatibility. Consult a chemical compatibility chart to match the fluid with the correct valve body and seal materials. Also, consider operating temperature, pressure, and flow rate.