China offers numerous manufacturers for high-pressure Brass Solenoid Valve products. Buyers seek reliable partners for various industrial applications. These suppliers provide a wide range of Solenoid Valve options. They also offer diverse Pneumatic Components, including the essential Pneumatic Cylinder. Some specialize as a Custom Solenoid Valve Manufacturer, while others produce specific items like the Stainless Steel Solenoid Valve. Evaluating supplier quality and technical support remains crucial for successful sourcing. This guide highlights top Chinese suppliers and key considerations for buyers.

Key Takeaways

- Many Chinese companies make good high-pressure brass solenoid valves. They offer different types for various uses.

- Look for suppliers with quality certificates like ISO 9001 and CE. These show they follow good manufacturing rules.

- Always check the materials used and how products are tested. This makes sure the valves are strong and work well.

- Good communication with suppliers is very important. Clearly tell them what you need and ask for regular updates.

- Understand things like how many valves you must buy (MOQ) and how long it takes to get them. This helps you plan better.

Leading Chinese Manufacturers of High-Pressure Brass Solenoid Valves

China hosts a robust manufacturing sector for high-pressure brass solenoid valves. Several companies stand out for their product quality, innovation, and customer service. These manufacturers offer diverse solutions for various industrial needs.

Shenzhen Wofly Technology Co., Ltd.: Product Range and Specializations

Shenzhen Wofly Technology Co., Ltd. specializes in a broad array of fluid control components. The company offers high-pressure brass solenoid valves designed for demanding applications. Their product range includes two-way, three-way, and four-way configurations. They also provide valves with various port sizes and voltage options. Wofly focuses on precision engineering. This ensures reliable performance under extreme pressure conditions. Their specialization extends to customized solutions. They meet specific client requirements for flow control and media compatibility.

Shanghai Tengen Electric Co., Ltd.: Quality Standards and Certifications for Brass Solenoid Valve

Shanghai Tengen Electric Co., Ltd. maintains a strong commitment to quality in its manufacturing processes. The company adheres to international quality standards for its products, including the Brass Solenoid Valve. They typically hold ISO 9001 certification. This demonstrates their dedication to consistent quality management systems. Many of their products also carry CE certification. This indicates compliance with European safety, health, and environmental protection requirements. Tengen Electric implements rigorous testing protocols. These protocols ensure each valve meets performance specifications and durability standards before leaving the factory.

Ningbo SENYA Pneumatic Technology Co., Ltd.: Customization and Technical Support

Ningbo SENYA Pneumatic Technology Co., Ltd. excels in providing tailored solutions and comprehensive support. The company has focused on producing valves, cylinders, and other pneumatic-related products since 1994. They adhere to customer value maximization as their product development and manufacturing principle. This commitment implies a willingness to meet client demands and provide flexible solutions. It extends to customization and support for their products like brass solenoid valves. Customers can consult staff for details regarding specific product customization. SENYA also offers robust technical assistance. They provide video technical support to help clients with installation and troubleshooting. Furthermore, marketing support is available; customers should consult staff for more information on these services.

Zhejiang Xinhai Valve Manufacturing Co., Ltd.: Cost-Effectiveness and Volume Production of Brass Solenoid Valve

Zhejiang Xinhai Valve Manufacturing Co., Ltd. stands out for its commitment to cost-effectiveness and high-volume production. The company has optimized its manufacturing processes to deliver competitive pricing without compromising product quality. They leverage efficient production lines and economies of scale. This allows them to produce large quantities of valves consistently. Buyers benefit from their ability to fulfill substantial orders promptly. Xinhai Valve maintains a robust supply chain. This ensures a steady flow of materials and components. Their focus on streamlined operations makes them a reliable partner for projects requiring numerous valves. They provide a dependable source for high-pressure Brass Solenoid Valve units.

YUYAO NO.4 INSTRUMENT FACTORY: Innovation and Specialized High-Pressure Brass Solenoid Valve Applications

YUYAO NO.4 INSTRUMENT FACTORY distinguishes itself through innovation and specialized applications for high-pressure brass solenoid valves. The factory offers an extensive range of valves. These valves are suitable for various media, including steam, gas, liquid, and even aggressive substances. They also provide tailored solutions to meet specialized industrial requirements. This customization capability ensures clients receive products perfectly suited to their unique needs. YUYAO NO.4 INSTRUMENT FACTORY engineers its products for exceptional durability. Their valves are designed to withstand millions of cycles without performance degradation, ensuring a long service life.

The factory lists "High Pressure Solenoid Valve" as a core product category. They offer several specialized valve types:

- High-temperature-resistant valves operate effectively up to 350°C.

- Explosion-proof solenoid valves are designed for use in hazardous environments.

- Stainless steel valves cater to corrosive applications.

- Compact pilot-operated valves suit low-pressure systems.

YUYAO NO.4 INSTRUMENT FACTORY also provides a range of high-pressure brass solenoid valves with varying interface sizes and working pressures. The table below illustrates some common models and their specifications:

| Model | Interface Size | Working Pressure (bar) – Brass |

|---|---|---|

| ZW-10N | 3/8" | 0~10 |

| ZW-15N | 1/2" | 0~10 |

| ZW-20N | 3/4" | 0~10 |

| ZW-25N | 1" | 0~10 |

| ZW-32N | 1 1/4" | 0~10 |

| ZW-40N | 1 1/2" | 0~10 |

| ZW-50N | 2" | 0~10 |

This diverse offering highlights their capability to address complex and demanding industrial challenges.

Additional Reputable Chinese Brass Solenoid Valve Suppliers

Beyond the major players, several other Chinese manufacturers consistently deliver high-quality brass solenoid valves. These companies offer specialized expertise and diverse product lines, catering to a wide range of industrial demands.

Zhejiang Oujin Valve Co., Ltd.: Comprehensive Brass Valve Solutions

Zhejiang Oujin Valve Co., Ltd. provides a comprehensive array of brass valve solutions. They specialize in manufacturing various types of brass valves essential for fluid control systems. Their product portfolio includes brass ball valves, known for their excellent shut-off capabilities. They also produce reliable gate valves, suitable for applications requiring full flow with minimal pressure drop. Furthermore, Oujin Valve offers check valves, which prevent backflow in pipelines, and HVAC valves, specifically designed for heating, ventilation, and air conditioning systems. This broad offering makes them a versatile supplier for many industrial and commercial projects.

Ningbo Jiekelong Precision Manufacturing Co., Ltd.: Precision Engineering for Brass Solenoid Valve

Ningbo Jiekelong Precision Manufacturing Co., Ltd. focuses on precision engineering in its manufacturing processes. The company employs advanced techniques to produce high-quality components, including the Brass Solenoid Valve. They emphasize tight tolerances and consistent product performance. Their engineering team utilizes sophisticated machinery and rigorous quality control measures. This ensures each valve meets exact specifications. Customers rely on their precision-engineered products for critical applications where accuracy and reliability are paramount. Jiekelong’s commitment to precision minimizes defects and enhances the longevity of their valves.

Shanghai Qinye Industrial Co., Ltd.: Diverse Industrial Brass Solenoid Valve Offerings

Shanghai Qinye Industrial Co., Ltd. offers a diverse range of industrial brass solenoid valve products. They cater to various sectors, providing solutions for different media, pressure ratings, and temperature requirements. Their extensive catalog includes valves for water, air, oil, and gas applications. Qinye Industrial also supplies valves in multiple sizes and configurations. This diversity allows customers to find the exact valve needed for their specific industrial processes. The company prides itself on its ability to adapt to market needs and provide versatile, high-performance valve options.

China SNS Pneumatic: Pneumatic Components and Brass Solenoid Valve Expertise

China SNS Pneumatic stands as a prominent supplier of pneumatic components, established in 1999. The company demonstrates extensive expertise across a wide range of products. Their capabilities encompass air combination units, cylinders, valves, and various accessories. They also handle hydraulic components.

SNS Pneumatic offers specific products that highlight their comprehensive range. These include the SNS pneumatic AR Series air source treatment pressure control air regulator. They also provide the SNS AC Series pneumatic air source treatment unit FRL combination air filter regulator lubricator. For control, they manufacture the SNS 4V2 Series Aluminum Alloy Solenoid Valve Air Control 5-way 12V 24V 110V 240V. Additionally, they produce the SNS 2W series control element direct-acting type brass solenoid water valve. Their cylinder offerings include the SNS DNC Series Double Acting Aluminum Alloy Standard Pneumatic Air Cylinder and the SNS SC Series aluminum alloy double/single acting standard pneumatic air cylinder. For connections, they supply the SNS SPC Series Male Thread Straight Brass Push To Connect Air Quick Pneumatic Fitting.

The company’s expertise spans several key pneumatic component categories. These include air source treatment, control components, executive components, and auxiliary components. They also specialize in pneumatic tools, vacuum components, and hydraulic components. Their specific expertise in brass solenoid valves is notable. They produce the SNS 2WS Series solenoid valve pneumatic brass waterproof solenoid valve. They also offer the SNS 2WK Series Normally Open brass water Solenoid Valve with 12V, 24VDC, 220V. Furthermore, they manufacture the SNS brand brass 2/2 way normally closed 3/8 inch waterproof solenoid valve. The SNS 2W series control element direct-acting type brass solenoid water valve is another key product. They also provide the SNS SMF-D series Straight angle solenoid control floating electric pneumatic pulse solenoid valve and the SNS SMF-J series Straight angle solenoid control floating electric pneumatic pulse solenoid valve.

KIO: Professional High-Pressure Brass Solenoid Valve Manufacturing

KIO has established itself as a professional manufacturer specializing in high-pressure brass solenoid valves. The company focuses on delivering robust and reliable valve solutions for demanding industrial environments. They employ advanced manufacturing techniques to ensure the precision and durability of their products. KIO’s commitment to quality is evident in its rigorous testing procedures. These procedures guarantee that each valve meets stringent performance standards before shipment. They offer a variety of configurations to suit different pressure ratings and flow requirements. KIO’s engineering team works to innovate and improve valve designs. This ensures their products remain at the forefront of fluid control technology. Customers rely on KIO for their expertise in producing high-performance valves for critical applications.

Evaluating Supplier Quality and Reliability for High-Pressure Brass Solenoid Valve

Understanding ISO 9001 and CE Certifications

Buyers must assess a supplier’s quality and reliability. Certifications like ISO 9001 and CE mark a manufacturer’s commitment to quality. ISO 9001 demonstrates a company’s adherence to international quality management standards. This certification ensures consistent product quality and continuous improvement processes. CE certification indicates a product meets European safety, health, and environmental protection requirements. These certifications provide assurance regarding a supplier’s manufacturing practices and product compliance.

Material Sourcing and Brass Alloy Quality for Solenoid Valves

The quality of raw materials directly impacts the performance and longevity of solenoid valves. Suppliers should source high-grade brass alloys. High-quality brass offers excellent corrosion resistance and mechanical strength. Manufacturers must ensure their brass alloys meet specific industry standards. This guarantees the valve’s ability to withstand high pressures and various media. Reputable suppliers often provide material certifications. These documents verify the composition and quality of the brass used in their products.

Rigorous Testing Procedures and Quality Control for Brass Solenoid Valve

Effective quality control involves rigorous testing procedures. Suppliers perform pressure cycling tests and endurance trials. They also conduct environmental stress testing. Leak testing and cycle life testing verify the valve’s durability. Pressure testing ensures the valve operates safely under specified conditions. Manufacturers collaborate with third-party testing companies for quality assurance. They evaluate products against prescribed local and international standards. This process obtains necessary safety documentation and certification markings. These steps ensure compliance with industry standards and regulations. They also verify reliability and safety before market release. Technicians check electrical components, such as the solenoid coil. They also inspect mechanical components, including the valve itself. Using a multimeter, they test the resistance and voltage of the solenoid.

Warranty and After-Sales Service for High-Pressure Brass Solenoid Valve

A supplier’s commitment to warranty and after-sales service is crucial. These aspects reflect their confidence in product quality. They also show their dedication to customer satisfaction. Reputable manufacturers offer clear warranty policies. They also provide robust support after the sale. This ensures buyers receive assistance when needed.

Suppliers typically offer a basic warranty period.

- A common offering is a 3-month seller’s warranty for defective items.

- If an item is defective within this period, the supplier usually offers a replacement. They provide this replacement at no extra charge. This includes shipping costs once they receive the defective item.

- For defects occurring after 3 months, buyers can still return the item. The supplier then contacts the manufacturers for warranty claims. Buyers might need to cover shipping costs for the replacement item in these cases.

Beyond the warranty, comprehensive after-sales service is vital. This support helps customers maximize their product’s value. It also ensures smooth operation.

- Suppliers often provide detailed product introductions. This helps users understand their new equipment.

- Assistance with mounting is another common service. This ensures correct installation.

- Debugging support helps resolve operational issues quickly.

- General technical support is also available. This addresses any questions or concerns customers may have. These services collectively enhance the user experience. They also build long-term trust between buyers and suppliers.

Key Factors for Selecting the Right High-Pressure Brass Solenoid Valve Supplier

Selecting an appropriate supplier requires careful evaluation of several key factors. Buyers must consider product details, manufacturing capabilities, and financial terms. This ensures a successful partnership and reliable product delivery.

Product Specifications and Performance Requirements

Buyers must clearly define their product specifications and performance needs. Brass valves suit water systems, air with minimal moisture, low-pressure steam, and automotive fluid management. However, brass has modest corrosion resistance. It is unsuitable for corrosive or acidic flow applications. Key specifications include:

- Material: Ensure compatibility with the media.

- Connection Size and Type: Match piping for proper flow and installation.

- Function: Determine if normally open, normally closed, or bistable operation is required.

- Voltage: Match the power supply (AC or DC).

- Seal Material: Select based on media compatibility (e.g., NBR, EPDM, Viton).

- Pressure Rating: The valve must withstand the system’s maximum pressure.

- Flow Rate (Kv Value): Ensure the valve provides the necessary flow capacity.

- Response Time: Critical for dynamic systems requiring rapid switching.

- Certifications: Confirm compliance with relevant industry standards like ISO, ANSI, or CE.

Production Capacity and Lead Times for Brass Solenoid Valve Orders

A supplier’s production capacity directly impacts order fulfillment. Large-scale manufacturers can handle significant volumes. For example, Yuyao Yongchuang Solenoid Valve Co., Ltd. reports a production capacity of 200,000 pieces per month for solenoid valves. Other companies like Dongguan Yanlun Electric and Yuyao Yongchuang Solenoid Valve operate 14,000m² plants. This indicates their ability to manage bulk contracts. Smaller facilities, such as Ningbo Fenghua Shengling Pneumatic Machinery Electric Co., Ltd. with 7,100m², suit mid-tier orders. Buyers should discuss lead times for their specific order size. This ensures timely delivery for project schedules.

Pricing Structures and Payment Terms

Understanding pricing structures and payment terms is essential for financial planning. Chinese suppliers commonly offer Telegraphic Transfer (T/T). This typically involves an upfront deposit, usually 20% to 50%, before production. The remaining balance becomes due upon shipment or document receipt. Exporters release shipping documents only after full payment. Letter of Credit (L/C) at Sight provides a secure payment method for larger orders or new relationships. A bank guarantees payment once all required shipping documents comply with L/C terms. Payment occurs immediately upon document verification. Open Account (O/A) terms are rare. Suppliers reserve them for highly trusted, long-standing partners due to the significant risk to the exporter.

Communication and Responsiveness

Effective communication is vital when selecting a supplier. Buyers need clear and timely responses from manufacturers. A responsive supplier can quickly address questions and provide necessary information. This ensures project timelines remain on track. Suppliers should offer multiple communication channels, such as email, phone, or messaging apps. They must also demonstrate an understanding of technical specifications. Clear communication helps avoid misunderstandings about product requirements. It also builds trust between the buyer and the manufacturer. A supplier’s ability to communicate effectively directly impacts the success of the sourcing process.

Minimum Order Quantities (MOQs) for Brass Solenoid Valve

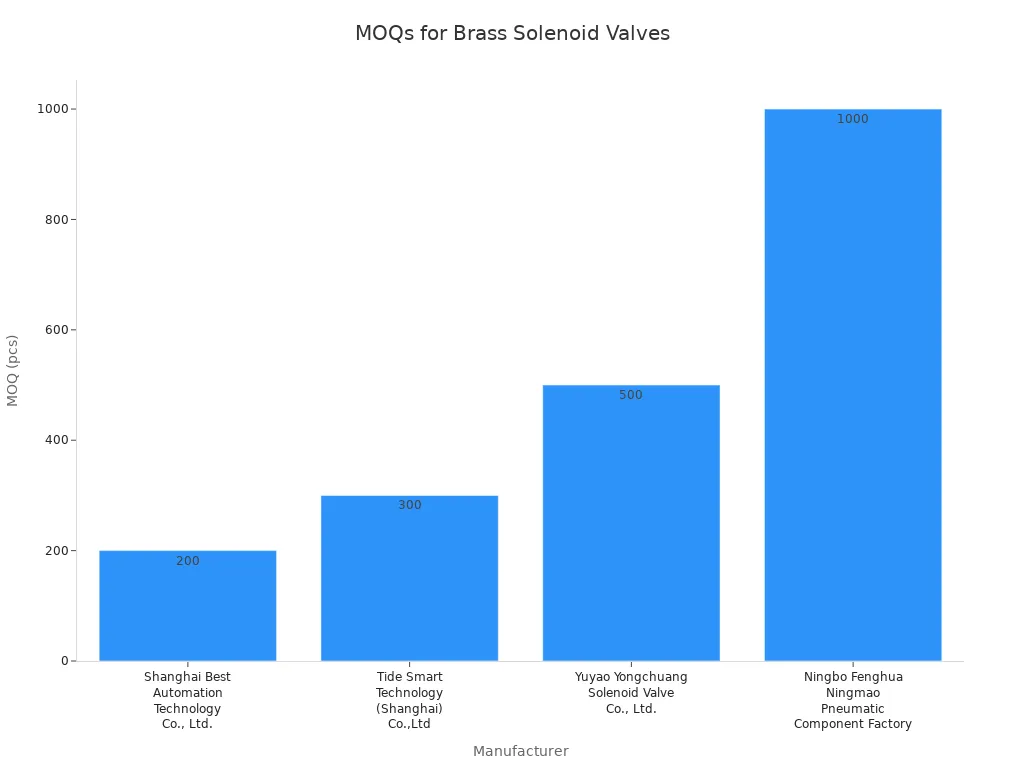

Minimum Order Quantities (MOQs) are a key factor for buyers. MOQs represent the fewest units a supplier will produce per order. These quantities vary significantly among Chinese manufacturers. One manufacturer offers a low MOQ for as few as 100 pieces, showing a flexible approach. Other suppliers have different requirements.

| Supplier | MOQ |

|---|---|

| Yuyao Yongchuang Solenoid Valve Co., Ltd. | 500 pcs |

| Ningbo Fenghua Ningmao Pneumatic Component Factory | 1,000 pcs |

| Tide Smart Technology (Shanghai) Co.,Ltd | 300 pcs |

| Shanghai Best Automation Technology Co., Ltd. | 200 pcs |

This chart further illustrates the range of MOQs from various manufacturers:

Most suppliers accept custom designs starting from 100–500 units. Smaller buyers can negotiate lower MOQs. This might involve accepting slightly longer lead times or sharing tooling costs. Lead times also depend on order volume.

| Quantity (pieces) | Lead time (days) |

|---|---|

| 1 – 200 | 15 |

| 201 – 1000 | 20 |

| > 1000 | To be negotiated |

For specific items, MOQs can be very low. For example, a 1/4” 120/60 110/50 8320G174 Solenoid Valve has a Minimum Order Quantity (MOQ) of 1 piece. Buyers should always confirm MOQs directly with suppliers.

Navigating Challenges in Sourcing High-Pressure Brass Solenoid Valve from China

Sourcing components from China presents opportunities and challenges. Buyers must understand potential obstacles. They can then develop strategies to mitigate risks.

Quality Discrepancies and Mitigation Strategies

Quality discrepancies sometimes arise when sourcing from China. These issues can include incorrect specifications or substandard materials. Buyers prevent these problems with clear communication. They provide detailed product specifications and technical drawings. Factory audits help assess a supplier’s production capabilities and quality control systems. Pre-shipment inspections by third parties verify product quality before shipping. These steps ensure products meet required standards.

Intellectual Property Protection for Brass Solenoid Valve Designs

Protecting intellectual property (IP) is a significant concern. Suppliers might replicate designs without authorization. Buyers safeguard their designs through non-disclosure agreements (NDAs). They register patents in China for unique product features. Choosing reputable suppliers with a strong track record also reduces IP risks. Building long-term relationships based on trust further protects proprietary information.

Logistics and Shipping Considerations for International Orders

International orders require careful planning for logistics and shipping. High-pressure brass solenoid valves must comply with American standards. These include ASME B16.34, API 6D, and NSF/ANSI 61. Many Chinese suppliers may not know U.S. requirements. Third-party testing, such as SGS or Intertek, often becomes necessary. Buyers request Material Test Reports (MTRs) and Certificates of Conformance (CoC). This avoids customs detention.

Verifying suppliers also mitigates risks. Buyers check ISO 9001 certifications and legal registration via the China National Enterprise Information System. Independent auditors assess production capacity and raw material origin. They also confirm lead times. Destructive tests confirm thread accuracy and pressure ratings.

Incoterms, like FOB or EXW, impact costs and responsibilities. Sea freight is common for large shipments. A 20-foot container from Shanghai to Los Angeles costs $1,800-$3,500. Air freight, at $5-$8/kg, suits urgent or smaller orders. Freight forwarders, such as DHL Global Forwarding, assist with documentation and tracking. Buyers account for potential delays at busy U.S. West Coast ports, which can last 10-20 days. Packaging should be ISTA 3A compliant.

High-pressure brass solenoid valves, classified under HTS 8481.80.0040, face a 2.5% MFN duty. They also incur a 25% Section 301 charge. Anti-dumping duties may apply if prices are too low. Engaging a licensed customs broker, like Livingston International, is advisable. They file through the Automated Commercial Environment (ACE). They also ensure accurate commercial invoices with correct HS codes. Tools like Flexport’s Duty Calculator estimate landed costs. Incorrect HTS classification leads to significant penalties.

Cultural and Language Barriers in Supplier Communication

Buyers often encounter cultural and language barriers when communicating with Chinese suppliers. These differences can lead to misunderstandings and delays. Most Chinese business professionals use Mandarin. English proficiency varies among individuals. Therefore, buyers should use clear, simple English in all written and verbal communications. Avoid jargon, slang, and complex sentence structures.

Translation tools can assist, but buyers must use them cautiously. Direct translations sometimes miss nuances or create incorrect meanings. Confirm critical details through multiple channels or rephrase questions. This ensures mutual understanding.

Cultural differences also play a significant role. Chinese business culture often values indirect communication. It emphasizes building long-term relationships and "saving face." Direct criticism or aggressive negotiation tactics can be counterproductive. Instead, adopt a patient and respectful approach. Focus on finding mutually beneficial solutions.

Consider hiring a local interpreter or a sourcing agent with cultural expertise. These professionals bridge communication gaps effectively. They also navigate cultural sensitivities. This investment often prevents costly errors and fosters stronger supplier relationships. Clear communication is paramount for specifying product requirements, such as those for a high-pressure Brass Solenoid Valve. It also helps in resolving issues efficiently. Building trust through consistent and respectful interaction ultimately leads to more successful partnerships.

Best Practices for Effective Communication with Brass Solenoid Valve Suppliers

Effective communication forms the foundation of successful supplier relationships. Clear and consistent interaction minimizes misunderstandings. It also ensures the timely delivery of high-quality products.

Clear Specification Documentation for High-Pressure Brass Solenoid Valve

Precise documentation prevents misunderstandings with suppliers. It ensures they manufacture the correct product. Documentation should detail construction materials. This includes the valve body (forged brass) and armature (stainless steel with Teflon or Viton seats). It also covers the spring (stainless steel) and O-ring (Viton). The solenoid tube (stainless steel), coil spacer plate (304 stainless steel), and hardware (304 stainless steel) also require specification.

Key features must be clear. These include the 1/4" BSP size and normally closed function. Direct acting operation and a forged brass body are also important. Specify PTFE or FKM seats. The pressure range should be 0 to 150 BAR. Note suitability for petrochemical media. Operational details are crucial. These include a -10°C to 120°C temperature range. Mention coil and LED DIN plug or flying lead. State installable orientation (upright preferred). Confirm design for high-pressure applications.

Detailed specifications for models like B55H are essential. Include port size (1/4 BSP) and orifice diameter (1.2mm to 5mm). CV values (0.07 to 0.64) are important. Pressure ranges for AC (0-150 BAR to 0-15 BAR) and DC (0-105 BAR to 0-10 BAR) are necessary. Media temperature (-10°C to 120°C) and coil specifications (e.g., SC-E16H, 45 Volt Amps, 30 Watts, Class H Insulation, 100% ED DIN Plug) complete the picture. List available voltages: 12vDC, 24vDC, 24vAC, 110vAC, 240vAC, 415vAC.

Other critical information includes media compatibility (type, temperature, viscosity). This dictates seal and valve body materials. Pressure, fluid flow rate, and orifice size determine the operating principle. Electrical specifications (voltage, power, frequency) ensure coil compatibility. Port size and connection type integrate with piping. Operating environment and certifications (IP Rating, Explosion Proof) address installation. Response time and cycle life are crucial for performance.

Regular Progress Updates and Project Management

Consistent communication regarding project status is vital. Buyers should establish a schedule for updates. This ensures all parties remain informed. Regular check-ins help manage expectations. They also ensure timely delivery. Suppliers should provide progress reports. These reports detail manufacturing stages and potential delays. Proactive communication about issues allows for quick resolution. Effective project management involves setting clear milestones. It also includes monitoring adherence to these timelines.

Utilizing Communication Tools and Platforms

Choosing appropriate communication tools enhances efficiency. Email remains a primary method for formal documentation. It provides a written record of discussions and agreements. Instant messaging platforms facilitate quick questions and urgent updates. Video conferencing tools allow for face-to-face discussions. These are useful for complex technical explanations or negotiations. Project management software can track tasks and deadlines. It also shares documents securely. Buyers should agree on preferred communication channels with their suppliers. This streamlines interactions and avoids confusion.

Building Long-Term Relationships with Chinese Brass Solenoid Valve Manufacturers

Establishing enduring relationships with Chinese manufacturers offers significant advantages. These partnerships extend beyond transactional exchanges. They foster mutual trust and understanding. Buyers benefit from consistent quality, preferential pricing, and improved lead times. Manufacturers gain stable business and a deeper understanding of client needs.

Trust forms the bedrock of any successful long-term collaboration. Buyers demonstrate reliability through timely payments and clear communication. Manufacturers build trust by consistently delivering quality products and adhering to agreements. Transparency in all dealings strengthens this foundation. Both parties should share information openly. This includes production schedules, potential challenges, and market insights.

Consistent engagement is crucial. Regular communication, even outside of active orders, maintains rapport. This can involve sharing market trends or offering feedback on product performance. Visiting manufacturing facilities periodically also reinforces the relationship. It allows buyers to observe production processes firsthand. These visits also provide opportunities for face-to-face discussions.

Understanding cultural nuances also plays a vital role. Chinese business culture values harmony and long-term commitment. Patience and respect for local customs can significantly enhance interactions. Avoid aggressive negotiation tactics. Instead, focus on finding mutually beneficial solutions. This approach fosters goodwill and strengthens the partnership.

Investing in the relationship yields substantial returns. Manufacturers often prioritize long-term partners. They may offer exclusive product developments or customized solutions. This commitment ensures a steady supply of high-quality components. It also facilitates quicker problem resolution. A strong relationship with a manufacturer, especially for specialized items like a high-pressure valve, becomes a valuable asset.

This guide highlights leading Chinese manufacturers for high-pressure brass solenoid valves. These include Shenzhen Wofly Technology, Shanghai Tengen Electric, Ningbo SENYA Pneumatic Technology, Zhejiang Xinhai Valve Manufacturing, and YUYAO NO.4 INSTRUMENT FACTORY.

For successful sourcing, prioritize due diligence, clear specifications, and partnership alignment. Select suppliers with proven track records, robust quality systems, and responsive communication. Verify factories by requesting ISO 9001 certification, third-party inspection reports, and scheduling virtual audits. Balance cost with service level, scalability, and risk mitigation. The cheapest option may not always be the most economical. Building long-term relationships ensures consistent quality and reliable supply.

FAQ

What is a high-pressure brass solenoid valve used for?

High-pressure brass solenoid valves control fluid flow in demanding applications. They manage water, air, oil, and gas. Industries like petrochemical, automotive, and manufacturing use them. These valves ensure precise and reliable operation under high-pressure conditions.

Why choose a Chinese supplier for brass solenoid valves?

Chinese suppliers offer cost-effective solutions and high production capacity. They provide a wide range of products and customization options. Many manufacturers adhere to international quality standards. This makes them a competitive choice for global buyers.

How can buyers ensure quality when sourcing from China?

Buyers should conduct factory audits and request material certifications. They must also implement pre-shipment inspections. Clear communication of specifications and rigorous testing procedures are crucial. These steps help verify product quality and compliance.

What certifications are important for brass solenoid valves?

ISO 9001 certification indicates a supplier’s quality management system. CE certification shows compliance with European safety standards. Other relevant certifications include ASME, API, and NSF/ANSI 61 for specific applications. These ensure product reliability and safety.

What is the typical lead time for brass solenoid valve orders from China?

Lead times vary based on order quantity and customization. For smaller orders (1-200 pieces), lead times can be around 15 days. Larger orders may take 20 days or more. Buyers should negotiate specific lead times with their chosen supplier.