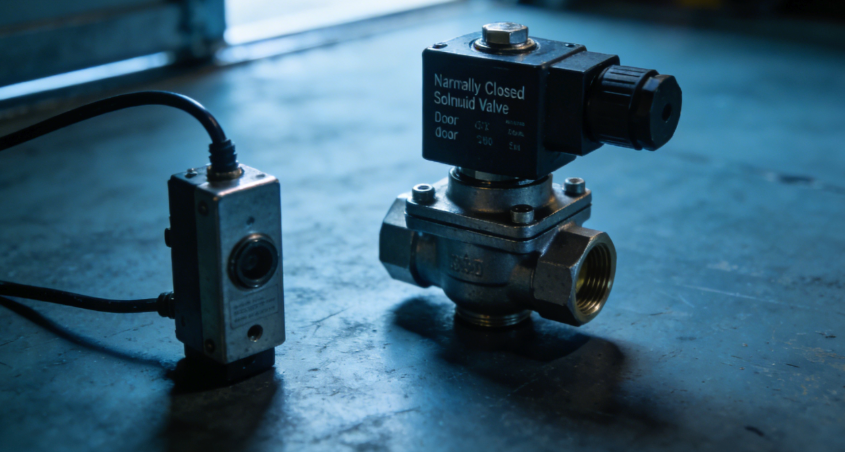

When a Normally Closed Solenoid Valve does not open, pinpointing the root cause is crucial. Technicians typically find issues are electrical, mechanical, or fluid-related. Understanding what is a normally closed solenoid valve helps diagnose the problem. Before any inspection or repair, always prioritize safety:

- Ensure the power supply is off and verify no voltage is present with a tester.

- Properly insulate and secure wires.

- Confirm the valve’s compatibility with the fluid.

- Operate the NC solenoid valve within its specified pressure and temperature limits.

This applies whether it is a normally closed solenoid valve for water or another medium. The normally closed solenoid valve explained simply means it stays closed without power. Knowing the normally closed solenoid valve working principle aids in safe diagnostics.

Key Takeaways

- Always check for electrical problems first. Make sure the valve coil gets the right power.

- Look for mechanical issues. Parts inside the valve can get stuck or damaged.

- Fluid problems can stop the valve. Check the pressure, flow direction, and fluid type.

- Keep the valve clean. Dirt and debris can stop it from working.

- Always put safety first. Turn off power before you check the valve.

Electrical Problems Preventing Your Normally Closed Solenoid Valve from Opening

Electrical issues are often the first place to look when a solenoid valve fails to open. These problems can range from a complete lack of power to subtle electrical inconsistencies.

No Power Supply to the Coil

A common reason a solenoid valve does not open is a lack of power to its coil. The coil needs electricity to create a magnetic field. This field pulls the plunger and opens the valve. First, check the power source. Look for tripped circuit breakers or blown fuses. Also, inspect all electrical connections. Loose wires prevent power from reaching the coil. Ensure the power supply is active and properly connected.

Incorrect Voltage or Amperage

Even with power, the wrong voltage or amperage can stop the valve from working. Solenoid coils operate with specific voltage requirements. Common voltage ratings include 6V, 12V, 24V, 120V, and 220V. For industrial applications, you often see DC 24V, 48V, and AC 127V, 220V, or 380V. Applying voltage too high or too low causes problems. Overvoltage generates excessive heat. This heat breaks down wire insulation. Even a 15% overvoltage can cut coil life in half. Undervoltage weakens the magnetic field. The plunger cannot move fully. For AC coils, undervoltage leads to continuous high inrush current and rapid burnout. Always verify the operating voltage is within 10% of the coil’s rated voltage.

Damaged or Burnt-Out Solenoid Coil

A damaged or burnt-out coil will not energize. Several factors cause coil damage. Overvoltage is a major culprit. Duty cycle violations also contribute. If a coil designed for intermittent use runs continuously, it overheats. Poor power quality, like voltage spikes, can cause instant damage. Mechanical issues also play a role. If the valve binds or sticks, the solenoid works harder. This increases current draw and heat. Environmental factors like high temperatures, humidity, or chemical exposure can degrade insulation. To diagnose a damaged coil, use a multimeter. Check for breaks or short circuits within the coil. Clear any foreign objects between the armature and the iron core. If the coil overheats, improve heat dissipation. Reduce frequent operations. Avoid long-term overload to prevent burnout.

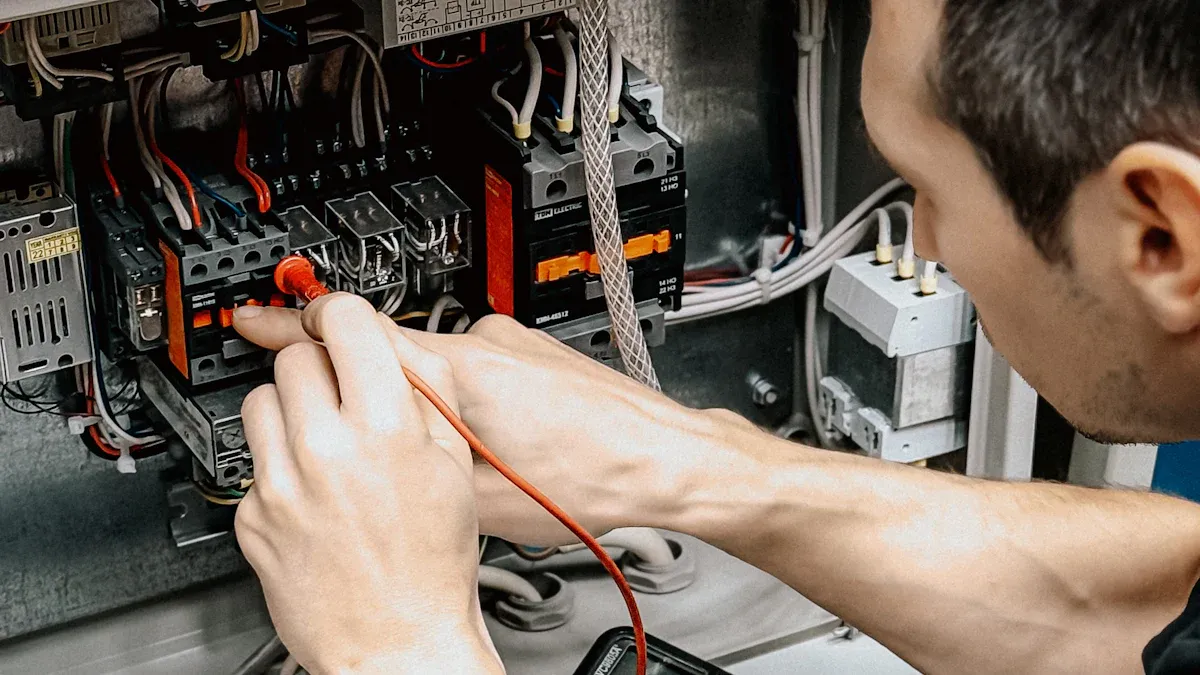

Faulty Wiring or Connections

Even if the coil itself is fine, problems with the wiring or connections can stop a Normally Closed Solenoid Valve from opening. Loose wires prevent electricity from flowing correctly. Corroded terminals also create resistance, which reduces the power reaching the coil. Technicians should always check for secure and clean connections.

Several wiring faults can prevent proper solenoid valve operation. Applying the wrong voltage to the coil can cause it to fail or burn out. For example, using a 120V coil with a 24V supply will not provide enough power. Similarly, using the wrong frequency, like 50Hz instead of 60Hz, can damage the coil over time. Electrical spikes, sudden surges from the power source, can also cause irreparable damage to coils. Surge protection is highly recommended to prevent this. Another common issue is water ingress or liquid contamination. If the coil’s enclosure rating (IP rating) is not sufficient for the environment, water or other liquids can enter and damage the coil.

The supplied power must always match the voltage indicated on the valve’s nameplate. Voltage fluctuations should remain within +10% to -15% of the nominal rating. If there is no continuity when checking the coil leads with a multimeter, the coil needs replacement. However, a jammed or worn pilot assembly can also cause coil burnout. Replacing the coil alone might not resolve the root issue in such cases.

Control Signal Issues

A solenoid valve needs a specific control signal to operate. If this signal is missing, incorrect, or corrupted, the valve will not open. This is especially true for more advanced proportional valves. Technicians should verify the control system is sending the correct command.

Solenoid valve controllers can read universal input signals. These include voltage, current, resistive, or Pulse Width Modulation (PWM). Specific input options often include 0-5 Vdc, 0-20 mA, 10 K Potentiometer Input, and 0-10 Vdc Input DC. Electronic regulators command proportional solenoids using PWM with a feedback signal. This ensures linearity between the output current and the input signal. It also makes the operation independent of external factors like supply voltage or temperature.

PWM is a DC supply voltage that switches on and off at a given frequency for a modulated period of time, known as the duty cycle. The duty cycle is the ‘on’ time of the voltage, expressed as a percentage of the time period. PWM signals are used for proportionally controlling solenoids by time-averaging the voltage and current. The working frequency for PWM is typically 120 Hz but can be adjusted from 50 Hz to 330 Hz. Typical uses of PWM controlled solenoids include proportional hydraulic or pneumatic solenoid valves, which use digital control, and proportional current control for position control.

Mechanical Failures in Your Normally Closed Solenoid Valve

Mechanical problems often prevent a Normally Closed Solenoid Valve from opening. These issues involve the physical parts of the valve. They can stop the internal components from moving as they should.

Stuck Plunger or Diaphragm

Sometimes, the plunger or diaphragm inside the valve gets stuck. This prevents the valve from opening. Many things can cause this problem.

The plunger moves with high friction (by dirt, damage or bending).

- Contamination: Tiny particles, debris, dirt, rust, or foreign objects can jam the plunger or diaphragm. This stops them from moving freely. It can also wear down seats and sealing surfaces.

- Corrosion and Material Mismatch: Corrosion can damage valve materials. It can make the bore rough where the plunger slides. This increases friction and makes the valve stick.

- Pressure and Temperature Outside the Design Window: Too little or too much pressure can stop the valve from opening or closing correctly. Operating outside the right temperature limits also causes problems.

- Damaged Internal Components: Bent tubes or worn seats can cause parts to bind or stick.

Debris or Contamination Inside the Valve

Debris inside the valve is a common mechanical issue. It stops the valve from working. Technicians must check the inside of valves for debris.

To clean a valve:

- Disconnect the power supply to the solenoid valve.

- Carefully disconnect the solenoid valve from the system.

- Methodically take apart the valve components. Separate the coil, housing, and internal parts.

- Inspect each component for wear or damage.

- Soak the disassembled components in a cleaning solution.

- Gently scrub away any remaining deposits with a soft brush.

- Rinse all components thoroughly with clean water.

- Use compressed air to blow out any lingering debris from the valve components.

Damaged Internal Components

Internal components of solenoid valves wear out over time. This wear affects seals and other mechanical parts like diaphragms. These parts can collect around ports and plungers, stopping their free movement.

Common parts that get damaged include:

- Seals on the Main Valve Core or Iron Core

- Spring

The solenoid coil can burn out if moisture causes insulation failure. This leads to too much current. Other things like a stiff spring or too much counterforce can also make the coil burn out. Coil malfunctions often happen because of overheating, electrical surges, or just old age. Also, leaks can occur when seals break down or foreign particles damage the valve seat.

Worn or Broken Spring

A worn or broken spring can also stop a Normally Closed Solenoid Valve from opening. The spring plays a vital role in the valve’s operation. It helps return the plunger to its original position. Over time, continuous cycling, changing pressures, and thermal expansion can weaken or break this spring. This wear and tear often causes premature failure for these parts.

A weak spring might not have enough force to push the plunger. This means the valve cannot open fully or at all. If the spring breaks completely, the plunger loses its support. This prevents the valve from moving correctly. A worn spring can cause the valve to fail to open. It can also cause the valve to fail to close. Technicians should inspect the spring for signs of fatigue or damage. They can replace it if necessary.

Physical Obstructions

Physical obstructions inside the valve can also prevent it from opening. These blockages stop the internal parts from moving freely. Debris, as mentioned before, is a common culprit. However, other types of obstructions exist.

For example, oil contamination can cause the spool to stick. Contaminants in hydraulic oil build up inside the valve. This makes the spool unable to move. Even tiny particles can block movement. Field experts often find contamination as the main reason for solenoid valve failure. Another issue is low oil temperature and high viscosity. Cold temperatures make hydraulic oil thick. This needs much more force to move the spool. The solenoid might not be strong enough. This problem often happens in winter or during cold start-ups. The valve might not work until the oil warms up and thins out. Other obstructions include mineral deposits or scale buildup. These can form in water or steam systems. They can coat internal surfaces and restrict movement.

Fluid Dynamics Affecting Your Normally Closed Solenoid Valve Operation

Fluid dynamics play a big role in how a solenoid valve works. If the fluid pressure is not right, the valve might not open.

Insufficient Inlet Pressure

Sometimes, a solenoid valve does not open because it does not get enough pressure at its inlet. Pilot-operated solenoid valves, for example, typically need a minimum inlet pressure or a differential pressure of 5 PSI to work. Without this pressure, they simply cannot operate. Direct-acting solenoid valves, however, can open and close regardless of pressure, as long as they do not exceed their maximum limits. They do not need a minimum inlet pressure.

When the inlet pressure is too low, especially for pneumatic solenoid valves, they might respond slowly or not at all. This happens because they need a specific air pressure to move. If the air supply pressure is too low, the valve will actuate slowly. This can come from restrictions in the supply lines or an air compressor that is too small. For pilot-operated valves, low pressure can cause erratic function or complete failure. The valve might be too big for the system, or the pressure drop across it is too low.

Excessive Back Pressure

Excessive back pressure can also stop a normally closed solenoid valve from working correctly. Back pressure is the pressure on the outlet side of the valve. If this pressure is too high, it can push against the valve’s internal parts. For instance, some industrial solenoid valves, like the VS*8-10 (for USA) ISO Interface Solenoid Valve, have a maximum operating pressure of 1.0 MPa.

If the back pressure goes above the valve’s rated limit, the valve will not close when it should. This happens because the high pressure pushes on the valve’s disk, working against the spring that normally closes it. If the outlet pressure becomes higher than the inlet pressure when the valve is closed, it creates a force on the disk. This force can make the valve leak or even open unexpectedly.

Incorrect Flow Direction

Installing a solenoid valve with the fluid flowing in the wrong direction can also cause problems. Solenoid valves have a specific design for fluid to flow in one direction. Manufacturers mark the correct flow direction on the valve body.

In pneumatic circuit symbols, arrows inside each flow box show the flow paths. These arrows tell you how the fluid moves through the valve in different positions. For multi-port valves, small arrows next to the symbol also indicate the flow path. Misinterpreting these flow direction arrows can lead to malfunctions. This is especially true if the system includes a check valve. Always make sure the fluid flows in the direction the valve expects.

Fluid Contamination

Dirty fluid can really mess up a solenoid valve. Many things can get into the fluid and cause trouble. These contaminants stop the valve from opening correctly. They can also damage the internal parts.

Common types of fluid contaminants include:

- Particulate matter: This means dust, dirt, sand, silt, and rust. These tiny bits can jam the valve’s moving parts.

- Chemical contaminants: These are things like acids, alkalis, salts, or residues from cleaning agents. They can cause corrosion or other bad chemical reactions inside the valve.

- Microorganisms: Bacteria, algae, or fungi can grow in the fluid. They form slimy films that block passages.

- Sediments: Worn-out valve parts, like seals and gaskets, can break down. Their pieces become sediment.

- Cross-contamination: This happens when different fluids mix. It can also occur if a valve fails.

- Airborne vapors and gases: These can dissolve into the fluid.

- Foreign materials: Sometimes, things get into the system during installation or maintenance.

Incorrect Fluid Type

Choosing the wrong fluid for a solenoid valve can cause big problems. Different fluids have unique properties. These properties affect how the valve works. It is very important to match the valve’s materials to the fluid it will control.

Using an unsuitable material, like a standard brass valve for strong acids, leads to failure. The valve body and seal materials must be compatible with the fluid. For example, rubbers and plastics can shrink, crack, or swell if they touch the wrong chemicals. Metals can corrode quickly. Temperature also matters a lot. Material compatibility can change a lot at different temperatures.

Here is a quick guide to compatibility:

- A – Excellent: The material works very well with the chemical. It has little to no effect.

- B – Good: There is a minor effect, like slight corrosion or discoloration.

- C – Fair: There is a moderate effect. You should not use it continuously.

- D – Severe Effect: Do not use this material at all. It has little resistance to the chemical.

- E – Insufficient Data: We do not have enough test results. More testing is needed.

Here are some recommended materials for common fluid types:

| Fluid Type | Recommended Housing Material | Recommended Sealing Material |

|---|---|---|

| Water, Air, Light Oil, Non-corrosive fluids | Brass | N/A |

| Corrosive Chemicals, Food & Beverage, Saltwater | Stainless Steel (304 or 316) | Viton (FKM) |

| Strong Acids, Alkalis | Plastic (PVC or Nylon) | N/A |

| Oil and Petroleum | N/A | NBR (Nitrile) |

| Hot Water and Steam | N/A | EPDM |

For aggressive or contaminated fluids, media-separated valves are a good choice. They keep the fluid away from the moving parts. Always check the chemical compatibility of both the valve housing and seal materials against the fluid.

When a normally closed solenoid valve does not open, technicians systematically check electrical, mechanical, and fluid aspects. They start with simple visual inspections, looking for loose connections or leaks. They also perform pressure and flow tests. Keeping a log of valve performance helps identify trends.

Address identified issues by cleaning debris or replacing specific components like coils or diaphragms. Sometimes, replacing the entire valve is more practical, especially if damage is extensive or repair costs are high.

If troubleshooting proves difficult, always consult a professional.

FAQ

Why does a solenoid valve hum when energized?

A humming sound often indicates an AC coil. This is usually normal. However, a loud hum might suggest low voltage or a mechanical issue. Check the power supply and internal components for binding.

Can technicians replace only the coil if it burns out?

Yes, technicians can often replace only the coil. First, identify the cause of burnout, like overvoltage or a stuck plunger. Address the root problem before installing a new coil to prevent future failures.

How often should technicians perform maintenance on a solenoid valve?

Maintenance frequency depends on the application and fluid. For critical systems or dirty fluids, inspect valves more often. Regular checks prevent debris buildup and component wear. 🛠️

What is the main difference between direct-acting and pilot-operated valves?

Direct-acting valves open directly when energized. They need no minimum pressure. Pilot-operated valves use system pressure to assist opening. They require a minimum pressure differential to function.

How can technicians check if a fluid is compatible with the valve materials?

Refer to the manufacturer’s chemical compatibility charts. These charts list suitable materials for various fluids and temperatures. Using incompatible fluids causes corrosion or seal degradation.