Solenoid valves play a crucial role in controlling fluid flow within industrial automation. These 2/2 way solenoid valves enable rapid and precise control over processes, leading to enhanced operational efficiency. By minimizing energy consumption and reducing downtime, solenoid valve applications significantly optimize manufacturing environments. Whether utilizing a brass solenoid valve or a stainless steel solenoid valve, their reliability ensures smooth operations in various industrial sectors.

Key Takeaways

- Solenoid valves provide rapid on/off control, making them ideal for applications that require quick response times.

- Using solenoid valves in automation systems enhances operational efficiency by reducing downtime and ensuring precise fluid control.

- Regular maintenance of solenoid valves, such as inspecting seals and cleaning contaminants, is crucial for optimal performance and reliability.

Solenoid Valves in Fluid Control

Solenoid valves serve a vital role in fluid control across various industrial applications. Their ability to provide rapid on/off control makes them ideal for systems that require quick response times. Industries utilize these valves to manage the flow of liquids and gases efficiently.

Recent advancements in solenoid valve technology have significantly improved their performance. For instance, fast-switching capabilities allow for rapid actuation, enhancing overall system responsiveness. Additionally, electronic control systems utilize high-speed microcontrollers to optimize valve response times.

Innovative valve seat and sealing mechanisms have also emerged, improving closure speed and reducing fluid resistance. These advancements ensure that solenoid valves maintain high accuracy in fluid control. In comparison to other valve types, solenoid valves offer simplicity and cost-effectiveness. They excel in applications that prioritize quick actuation, while control valves are better suited for scenarios requiring precise flow regulation.

Here are some key comparisons between solenoid valves and other valve types:

- Solenoid valves provide quick on/off control, ideal for rapid response applications.

- Control valves offer enhanced precision and flexibility for complex fluid control needs.

- Solenoid valves are generally simpler and more economical than control valves.

- Control valves excel in applications demanding accurate flow regulation and pressure control.

Overall, solenoid valves are essential for effective fluid control in industrial automation, ensuring processes run smoothly and efficiently.

Solenoid Valves in Automation Systems

Solenoid valves play a pivotal role in automation systems, particularly in controlling fluid flow and enhancing operational efficiency. These valves integrate seamlessly with programmable logic controllers (PLCs), allowing for precise automation of pneumatic systems. Their ability to control the flow of liquids and gases makes them essential for operating actuators in various applications.

Key benefits of using solenoid valves in automation systems include:

- Ultra-fast response times: Solenoid valves are designed for high-speed applications, ensuring quick actuation and minimizing delays.

- Reduced downtime: Their robust construction leads to fewer failures, resulting in lower maintenance costs.

- Pinpoint fluid control: These valves regulate the flow of materials accurately, reducing waste and ensuring consistent application.

Common types of solenoid valves used in automation include direct-acting and pilot valves. Direct-acting valves are suitable for smaller applications, while pilot valves are ideal for larger systems. The choice of valve depends on specific application demands, with ball valves often being favored for their flexibility and cost-effectiveness.

To maintain solenoid valves in automation systems, operators should follow these guidelines:

- Ensure the power supply matches coil specifications.

- Inspect seals and O-rings for wear and replace if necessary.

- Clean contaminants from valve openings and connections.

By adhering to these practices, manufacturers can enhance the reliability and efficiency of their automation systems, ultimately leading to improved productivity.

Solenoid Valves in HVAC Systems

Solenoid valves are integral to HVAC systems, providing efficient control of fluid flow. They enhance energy efficiency and ensure precise temperature regulation. These valves allow for rapid adjustments, which is crucial for maintaining optimal climate conditions in large facilities.

The benefits of using solenoid valves in HVAC systems include:

| Benefit | Description |

|---|---|

| Energy Efficiency | Coils are optimized to require less power, conserving energy and reducing operational costs. |

| Precise Temperature Control | Enables accurate modulation of fluids, maintaining desired temperatures consistently. |

| Quick Response Time | Rapid actuation allows for prompt adjustments to temperature fluctuations, optimizing performance. |

| Reduced Maintenance | Built for durability, requiring minimal maintenance, leading to decreased downtime and costs. |

In addition to their benefits, solenoid valves can experience common failure modes. These include:

-

Not opening or closing properly due to:

- No power to the coil

- Incorrect voltage or frequency

- Burnt coil

- High or low differential pressure

- Dirt on the membrane

- Corrosion

-

Leaking caused by:

- Impurities in the valve

- Damaged components

- Internal or external leakage

-

Overheating from electrical issues or inadequate cooling systems.

Solenoid valves contribute significantly to the automation of climate control in large-scale facilities. They enable precise control of fluid flow, facilitating energy efficiency through rapid opening and closing. Integration with smart building technologies allows for real-time monitoring and optimization of HVAC operations.

By utilizing solenoid valves, HVAC systems can achieve enhanced performance and reliability, ultimately leading to improved energy savings and operational efficiency.

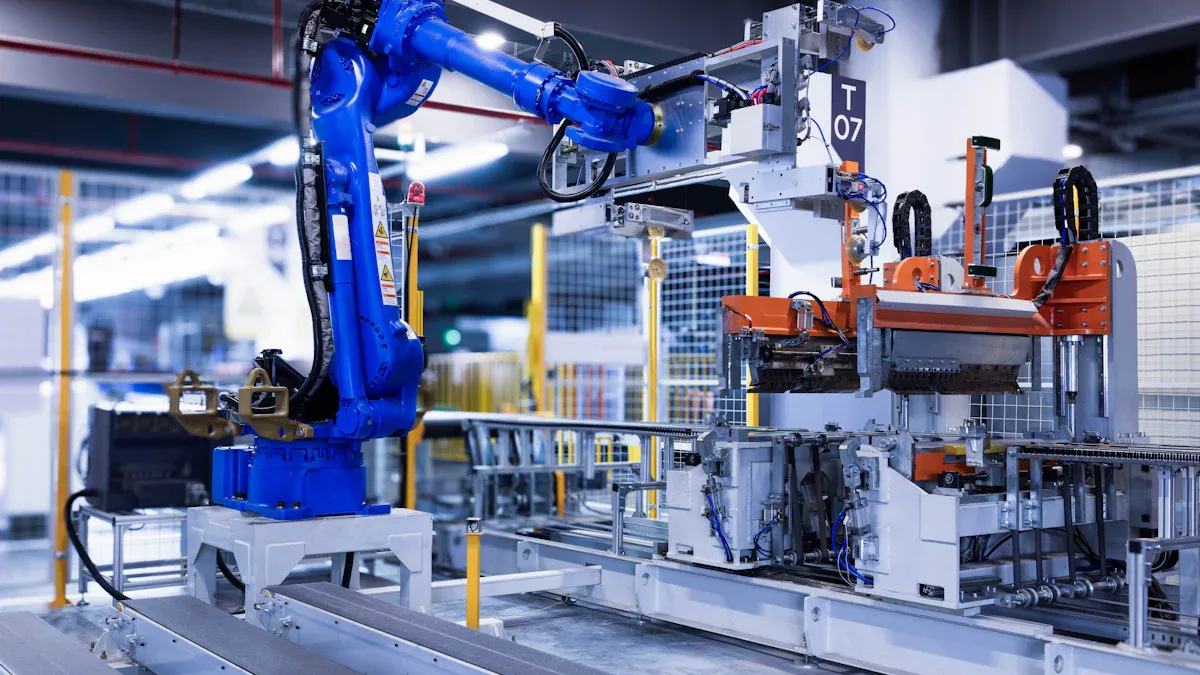

Solenoid Valves in Packaging Machinery

Solenoid valves are essential components in packaging machinery, automating various processes such as filling, sealing, and product movement. Their ability to provide rapid and precise control enhances the efficiency of packaging operations.

In packaging applications, solenoid valves serve multiple functions:

| Application | Description |

|---|---|

| Product Movement Control | Clippard Spider valves control the movement of products on conveyors or robotic arms for precise placement into containers. |

| Fluid Dispensing and Filling | These valves regulate the flow of liquids or powders in automated filling machines, ensuring minimal leakage and consistent control. |

| Pneumatic Sealing and Capping | Valves actuate machinery to secure caps or seals on containers, ensuring proper sealing without delays. |

Common types of packaging machinery that rely on solenoid valves include systems that control sorting processes, equipment used for sealing operations, and machinery that manages indexing functions.

The speed and accuracy of packaging operations depend significantly on solenoid valves. A fast-responding solenoid valve reduces idle time and enhances overall productivity in high-speed production environments. Delays in valve response can slow actuator movements, affecting cycle time and product positioning accuracy.

Safety standards for solenoid valves in packaging machinery are crucial. Compliance with standards such as IEC 61508 ensures that equipment can detect dangerous conditions and activate corrective mechanisms. Other relevant standards include IEC 61511, ISO 13849, and the Machine Directive (2006/42/EC).

By integrating solenoid valves into packaging machinery, manufacturers can achieve improved efficiency, safety, and reliability in their operations.

Solenoid Valves in Automotive Applications

Solenoid valves play a critical role in automotive applications, enhancing performance and safety across various systems. In fuel injection systems, these valves provide precise control over fuel flow. This precision improves efficiency and performance in modern vehicles. Their faster response times and adaptability to electronic control systems are essential for the increasing complexity of automotive technologies.

In braking systems, solenoid valves contribute significantly to safety and performance. The following table outlines their key functions:

| Function | Description |

|---|---|

| Brake Control | Activates solenoid valves to direct pressurized air to the brake chamber when the brake pedal is pressed. |

| ABS Support | Enables rapid modulation of brake pressure to prevent wheel lock-up by opening and closing valves multiple times per second. |

| EBS Integration | Distributes braking force evenly across all wheels, enhancing safety and control in modern vehicles. |

| Parking Brake and Trailer Control | Controls air for parking brakes and trailer connections, ensuring effective braking in various scenarios. |

| Fast Response Time | Responds almost instantly to electrical signals, crucial for systems like ABS. |

| High Precision Control | Regulates brake force with millisecond-level accuracy. |

| Compatibility with Electronic Systems | Essential for integration with electronic control units in modern brake systems. |

| Reliability and Durability | Designed to perform reliably in harsh conditions, ensuring long-lasting performance. |

Additionally, solenoid valves enhance automotive emission control systems. They help reduce emissions and comply with stringent environmental regulations. The integration of smart technologies allows for real-time monitoring and adjustment, ensuring better control over emissions.

Overall, solenoid valves are indispensable in automotive applications, improving fuel efficiency, safety, and environmental compliance.

Solenoid Valves in Process Control

Solenoid valves are critical in process control applications, ensuring system stability and efficiency. They regulate fluid flow in various industries, including automotive, medical, and manufacturing. Their precise operation enhances overall process reliability.

Key applications of solenoid valves in process control include:

| Application Area | Description |

|---|---|

| Automotive | Used in fuel injection, transmission control, and turbocharger systems for precise operation. |

| Pneumatic Systems | Regulate air or gas flow quickly and accurately for efficient operation. |

| Medical Equipment | Ensure accurate dosing in anesthesia machines and ventilators through precise control. |

| Water Treatment | Regulate water flow and handle corrosive chemicals for accurate dosing in treatment processes. |

| Heating and Cooling Systems | Manage hot or cold water flow to maintain desired temperatures. |

| Refrigeration Systems | Control refrigerant flow to ensure efficient system operation. |

| Aerospace | Provide quick and precise control in fuel and hydraulic systems for reliability. |

| Manufacturing Processes | Regulate fluid or gas flow for efficient production operations. |

| Food and Beverage Processing | Manage liquid and gas flow for accurate ingredient dosing and process efficiency. |

| Fire Protection Systems | Regulate flow of extinguishing agents for effective operation during emergencies. |

Solenoid valves contribute to reducing downtime in industrial process control systems. They feature self-diagnostic capabilities that help detect potential issues early. Condition monitoring sensors continuously assess valve performance. Predictive maintenance algorithms forecast maintenance needs, preventing unexpected failures.

Regulatory compliance is essential for solenoid valves in process control. Manufacturers must adhere to Good Manufacturing Practice (GMP) and FDA regulations. They must also conform to EU directives and provide documentation to ensure product quality.

By integrating solenoid valves into process control systems, industries can achieve enhanced efficiency and reliability. These valves facilitate remote monitoring and control, allowing operators to manage processes from a centralized location. This capability streamlines operations and minimizes human error, ultimately increasing productivity.

Solenoid valves are vital across various industrial automation sectors. They control fluid flow in applications such as beverage dispensers, pneumatic systems, and automotive technologies. Their reliability enhances efficiency and reduces maintenance costs. Recognizing these applications aids in better implementation and optimization, driving trends in smart manufacturing and IoT integration.

FAQ

What are solenoid valves used for in industrial automation?

Solenoid valves control fluid flow in various applications, enhancing efficiency and reliability in systems like HVAC, packaging, and automotive technologies.

How do solenoid valves improve energy efficiency?

These valves minimize energy consumption by providing rapid on/off control, reducing downtime, and optimizing fluid flow in automated systems.

What maintenance is required for solenoid valves?

Regular inspections of seals, O-rings, and coil specifications ensure optimal performance. Cleaning contaminants from valve openings also helps maintain functionality.