When selecting a Solenoid Valve, several factors are crucial for ensuring its durability and reliable performance, especially in water systems. These include material quality, pressure and temperature ratings, seal compatibility, coil specifications, and connection details. Incorrect material selection, for instance, can lead to premature degradation. In environments with corrosive chemicals, a stainless steel solenoid valve is often a superior choice compared to a brass vs stainless valve option. Applying incorrect voltage to the coil or operating the valve at excessively high temperatures can cause the unit to fail. This directly addresses What causes a solenoid valve to fail?, often pointing to electrical issues or thermal stress. Careful selection and proper installation are key to preventing common problems, thereby avoiding the need to learn how to fix a solenoid valve. This meticulous approach ensures reliable function for various applications, including its use as a solenoid valve for irrigation.

Key Takeaways

- Choose the right brass for your valve. Some brass types resist rust better in water.

- Check the valve’s pressure and temperature limits. The valve must handle your water system’s conditions.

- Pick the correct seal material. Different seals work best with different water types and temperatures.

- Match the valve’s electrical parts to your power supply. This keeps the valve working safely.

- Select the right connection type and size. This ensures good water flow and a proper fit.

Material Selection for a Durable Brass Solenoid Valve

Understanding Brass Alloys for Water Systems

Choosing the correct brass alloy is fundamental for a durable Solenoid Valve in water applications. Brass is an alloy primarily composed of copper and zinc. Manufacturers add other elements to enhance its properties for specific uses.

- Copper: This is the main material, typically making up 55% to 90% of the alloy.

- Zinc: It is present in amounts ranging from 5% to 45%.

- Additional Elements: Lead, nickel, manganese, and tin may be included in small proportions. These elements improve physical properties and adapt the brass for different environments.

The specific blend of these elements determines the brass’s strength, machinability, and resistance to various conditions.

Corrosion Resistance of Brass Solenoid Valves

Corrosion resistance is a critical factor for any material in contact with water. Different brass alloys exhibit varying levels of resistance to corrosion in water systems. The type of water, such as soft or hard water, also influences corrosion rates.

| Brass Alloy | Water Type | Corrosion Rate (mm/year) |

|---|---|---|

| C89833 (lead-free aluminum-brass) | Soft Water | 0.02 |

| C36000 (traditional brass) | Soft Water | 0.08 |

This table shows that lead-free aluminum-brass (C89833) offers significantly better corrosion resistance in soft water compared to traditional brass (C36000). Selecting an alloy with superior corrosion resistance extends the valve’s lifespan.

Manufacturing Standards for Brass Solenoid Valve Quality

Adherence to manufacturing standards ensures the quality and reliability of brass solenoid valves. These standards define material composition, dimensions, and performance criteria.

- ISO standards cover various aspects of fluid power and general valve specifications. They address dimensions, materials, and pressure ratings for valve bodies.

- Material and fluid power standards are crucial for body integrity and pressure ratings. They often accompany electrical and safety certifications.

For brass solenoid valves, the brass body material must comply with ASTM B280. This standard specifies the requirements for seamless copper tube for air conditioning and refrigeration field service. Following these standards guarantees the valve meets specific quality and performance benchmarks.

Performance Ratings: Pressure and Temperature for Brass Solenoid Valves

Operating Pressure Range for Solenoid Valve Durability

Selecting a brass solenoid valve requires careful consideration of its operating pressure range. The valve must withstand the maximum pressure of the water system without failing. Manufacturers design valves for specific pressure limits. Exceeding these limits can cause leaks or damage the valve’s internal components.

For residential and commercial plumbing, a 2-inch (50 mm) water Solenoid Valve typically handles pressures from 0.5 to 115 PSI. Other brass valves with a 3/4-inch NPTF connection often have a maximum water pressure rating of 100 PSIG. Some brass valves offer even higher pressure resistance, ranging from 0.5 to 1.6 MPa (approximately 72.5-232 PSI), with a pressure rating of 16 bar (about 232 PSI). These valves suit various water applications. Always match the valve’s pressure rating to the system’s expected operating and surge pressures.

Temperature Limits for Water Solenoid Valve Applications

Temperature significantly impacts a brass solenoid valve’s performance and lifespan. High temperatures can degrade seal materials and affect the coil’s insulation. Manufacturers specify a maximum operating temperature for each valve series.

| Valve Series | Maximum Operating Temperature |

|---|---|

| Jefferson 1314 Series | 356 ºF (180 ºC) |

| SV220-Series | 50 °C |

| SV222 through SV225 | 99°C (210°F) |

| SV4000A-Series | 182 °C (360°F) |

For hot water recirculation systems, choose valves designed for higher temperatures. Using a valve beyond its temperature limit can lead to premature failure of seals and other components.

Pressure Differential Impact on Solenoid Valve Operation

The pressure differential across a solenoid valve refers to the difference in pressure between its inlet and outlet ports. This factor is crucial for the valve’s proper operation. Pilot-operated valves, for example, require a minimum pressure differential to open or close effectively. Without this minimum difference, the valve may not actuate correctly. Direct-acting valves, however, do not rely on a pressure differential for operation. They can function from zero pressure up to their maximum rated pressure. Understanding the valve’s operating principle and its pressure differential requirements ensures reliable performance in the water system.

Seal Material Compatibility for Brass Solenoid Valve Longevity

Seal materials play a critical role in a brass Solenoid Valve’s long-term performance. The right seal prevents leaks and ensures efficient operation. Incompatible materials can lead to premature failure.

Common Seal Materials for Water Solenoid Valves

Several materials commonly serve as seals in water solenoid valves. Each material offers specific properties suitable for different applications.

- NBR (Nitrile Rubber): This material is common in general-purpose valves. Many 3-way brass solenoid valves use NBR seals.

- EPDM (Ethylene Propylene Diene Rubber): EPDM works excellently for water applications. Manufacturers often use it in water treatment and irrigation systems.

- Viton (FKM): Brass solenoid valves use Viton, especially for diaphragms. It provides good chemical resistance.

Choosing the correct seal material ensures the valve functions reliably.

Water Quality Effects on Solenoid Valve Seal Degradation

Water quality significantly impacts the lifespan of solenoid valve seals. Different water compositions can cause seals to degrade over time. For example, hard water contains minerals that can build up on seals, causing wear. Chlorinated water, common in municipal supplies, can chemically attack certain rubber compounds. This chemical attack makes seals brittle or soft. Poor water quality reduces the seal’s elasticity and sealing capability. Regular maintenance or selecting seals resistant to specific water conditions helps prevent early degradation.

Temperature and Chemical Resistance of Solenoid Valve Seals

Temperature and chemical resistance are vital factors for seal longevity. Different seal materials perform differently under varying conditions. For instance, Viton seals offer superior performance compared to NBR seals in many situations.

| Feature | Viton Seals | NBR Seals |

|---|---|---|

| Temperature Range | -20ºC to 210ºC | -30ºC to 100ºC |

| High Temp Use | Superior, especially for drastic changes | Inferior to Viton |

| Low Temp Use | Can stiffen and fail in dynamic situations | Stays somewhat flexible in freezing temperatures, better for cold, dynamic situations |

| Chemical Resistance | Resistant to acids, oils, gasses, silicon fluids, aromatic gasses, halogenated hydrocarbons; better for chemical processing | Resistant to petroleum oils, aliphatic hydrocarbon, hydraulic fluids, and water; best for general chemical resistance |

Viton handles higher temperatures and a wider range of chemicals. NBR performs better in colder, dynamic situations. Understanding these differences helps select the most durable seal for specific water applications.

Electrical Reliability and Connection for Brass Solenoid Valves

Coil Type and Electrical Specifications for Solenoid Valve Actuation

The coil is a vital part of a brass solenoid valve. It converts electrical energy into mechanical motion. Understanding coil types and electrical specifications ensures reliable valve actuation. AC solenoids initially use high power to open quickly. They then require less power to stay open, saving energy. DC solenoids draw consistent power. This can lead to higher overall energy use because they consume more power than needed to keep the valve open. Their power consumption increases slowly, causing a slower valve opening.

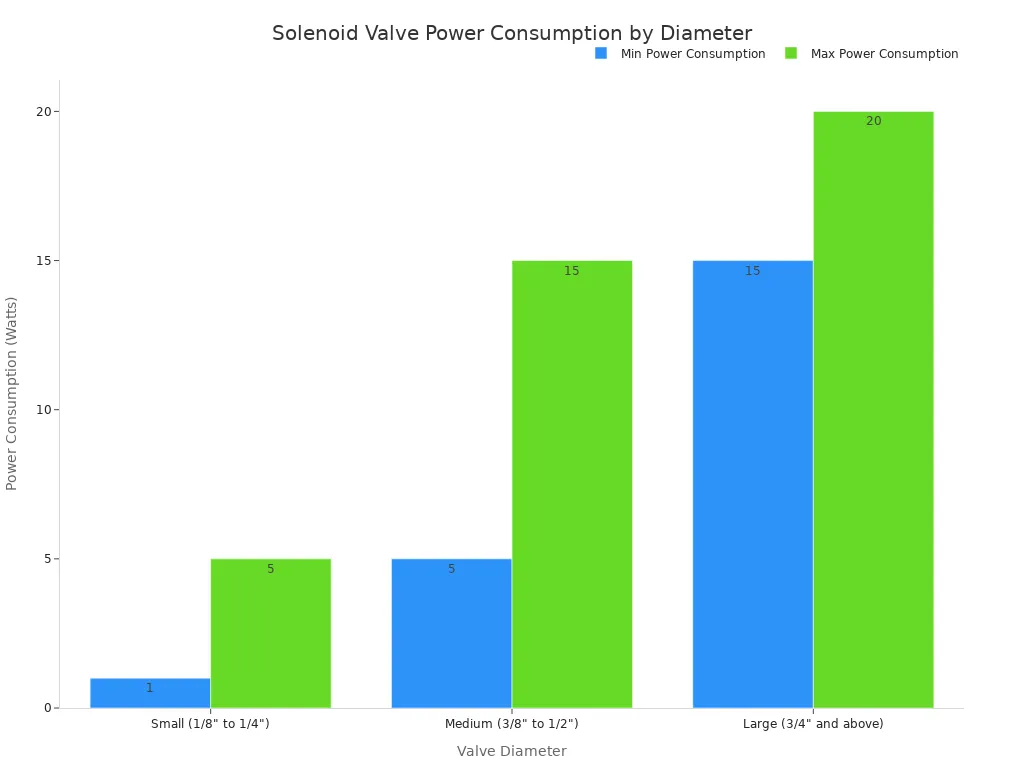

Different valve sizes have varying power needs.

| Valve Diameter | Typical Power Consumption (Watts) | Common Operating Voltages (V) |

|---|---|---|

| Small (1/8" to 1/4") | 1 to 5 | 12, 24, 110, 220 |

| Medium (3/8" to 1/2") | 5 to 15 | 12, 24, 110, 220 |

| Large (3/4" and above) | 15 or more | 12, 24, 110, 220 |

Matching the coil’s voltage and power to the system’s electrical supply prevents damage and ensures proper function.

Ingress Protection (IP) Rating for Solenoid Valve Protection

The Ingress Protection (IP) rating indicates a solenoid valve’s resistance to dust and water. This rating is crucial for valves in wet or dusty environments.

- IP65 rating: This rating means the device is dust-tight. It also protects against low-pressure water jets. Testing involves spraying 12.5 liters of water per minute for at least 15 minutes. The pressure is 30 kPa from a distance of 3 meters.

- IP67 rating: This rating offers complete protection from dust. It also protects against immersion in water up to 1 meter deep. The test requires immersion for 30 minutes or more. The depth is measured from the bottom of the object, with at least 15 cm from the top.

Choosing the correct IP rating ensures the valve’s electrical components remain safe and functional.

Connection Type and Size for Optimal Solenoid Valve Flow

Connection type and size are important for proper installation and flow. Brass solenoid valves commonly use NPT (National Pipe Thread) and BSP (British Standard Pipe) connections.

| Aspect | NPT (National Pipe Thread) | BSP (British Standard Pipe) |

|---|---|---|

| Standards | ASME B1.20.1 | ISO 228-1 (BSPP), ISO 7-1 (BSPT) |

| Thread Angle | 60 degrees | 55 degrees |

| Taper | Tapered (1/16 inch per inch) | BSPP: Parallel; BSPT: Tapered |

| Sealing Mechanism | Tapered fit, often with sealants | BSPP: Washer/O-ring; BSPT: Tapered fit, often with sealants |

| Common Nominal Sizes (inches) | 1/8, 1/4, 3/8, 1/2, 5/8, 3/4, 1, 1 1/4, 1 1/2, 2 | 1/8, 1/4, 3/8, 1/2, 5/8, 3/4, 1, 1 1/4, 1 1/2, 2 |

NPT threads are common in the U.S. They have a 60-degree tapered thread. This creates a seal through an interference fit. BSP threads are widely used globally. They have a 55-degree thread angle. BSPP threads are parallel and seal with a washer or O-ring. BSPT threads are tapered and form a seal as they screw together. Both NPT and BSP threads come in common sizes like 1/2 inch and 1 inch. Selecting the correct connection type and size ensures proper fit and efficient water flow.

Prioritizing material quality, appropriate pressure and temperature ratings, compatible seal materials, robust electrical components, and correct sizing is essential. A thorough evaluation of these factors ensures a reliable and long-lasting brass solenoid valve for any water application. Selecting the right solenoid valve prevents premature failure and maintains system efficiency. While high-quality valves may have a higher initial price, they offer substantial long-term savings. Conversely, low-quality or improperly selected valves lead to frequent replacements and maintenance, significantly increasing the total cost of ownership.