For water systems in 2025, the most durable Brass Solenoid Valve options truly stand out. They feature robust forged brass bodies, and high-grade internal sealing materials like EPDM or Viton are crucial for longevity. Robust coil encapsulation also makes a significant difference. These valves are specifically designed for continuous duty and high-pressure resistance. Understanding the differences, such as brass vs stainless valve options, helps buyers choose wisely. Regardless of the types of solenoid valves, whether you’re asking "What is a 2-way solenoid valve?" or considering "How do multi-way solenoid valves work?", durability remains a top priority.

Key Takeaways

- Choose valves made from forged brass. It is stronger and lasts longer than cast brass.

- Check the internal parts. EPDM or Viton seals and stainless steel plungers make valves more durable.

- Look for coils that are sealed well. This protects them from water and dust, making them last longer.

- Match the valve to your system’s needs. Consider water pressure, temperature, and how often the valve will run.

- Look for certifications like NSF/ANSI 61. These show the valve meets high safety and quality standards.

Understanding Brass Solenoid Valve Body Durability

Forged Brass vs. Cast Brass Solenoid Valve Bodies

The body of a solenoid valve forms its primary structure. Its material and manufacturing process greatly affect its lifespan. Forged brass and cast brass are the two main types. They offer very different levels of durability.

Forged brass is like a strong, dense piece of metal. Manufacturers heat brass and then press it into shape. This process makes the metal very compact. It removes tiny air pockets or flaws. This means a forged brass body is much stronger. It handles high pressure better. It also resists leaks more effectively. A Brass Solenoid Valve with a forged body offers superior structural integrity.

Cast brass is different. Manufacturers melt brass and pour it into a mold. As it cools, small air bubbles can get trapped inside. This makes cast brass less dense. It can have tiny pores. These pores might lead to leaks over time, especially under high pressure. Cast brass is often cheaper to make. However, it is not as durable as forged brass. For water systems, durability is key.

Tip: Always prioritize forged brass for critical water system applications. Its dense structure provides better resistance to pressure and corrosion.

Identifying Durable Forged Brass Solenoid Valves

How can you tell if a valve uses forged brass? First, look at the product description. Reputable manufacturers proudly state "forged brass body." They know it is a selling point. You might also notice a smoother, more uniform finish on forged valves. Cast valves can sometimes look a bit rougher.

Another clue is the weight. Forged brass is denser, so a forged Brass Solenoid Valve might feel heavier than a similar-sized cast one. Always check the technical specifications. These documents often detail the manufacturing process. They also list material grades. Choosing a valve from a well-known brand also helps. These brands usually invest in better materials and processes. They often provide certifications that confirm material quality.

Critical Internal Components for Brass Solenoid Valve Longevity

A valve’s body provides its shell, but its internal parts truly dictate its long-term performance. These components handle the actual fluid control. They must withstand constant movement, pressure, and chemical exposure.

Sealing Materials: EPDM vs. Viton for Water Systems

Sealing materials prevent leaks and ensure proper valve operation. For water systems, EPDM (Ethylene Propylene Diene Monomer) and Viton (Fluoroelastomer) are two popular choices. Each material offers distinct advantages.

EPDM is a synthetic rubber. It performs exceptionally well with water, steam, and many polar solvents. It resists ozone, weathering, and aging. This makes it a great general-purpose seal for most water applications.

Viton is a high-performance synthetic rubber. It offers superior resistance to oils, fuels, and many aggressive chemicals. It also handles higher temperatures better than EPDM.

When choosing between them, consider the specific chemicals in your water system.

- For standard industry chemicals like Roundup, Lexar EZ, or Atrazine, EPDM seals are recommended.

- For oil-based chemicals such as 2,4-D, MSO, and Crop Oil, Viton® seals are recommended.

Always match the seal material to the fluid it handles. This prevents premature degradation and ensures a leak-free system.

Plunger and Spring Materials in Brass Solenoid Valves

The plunger and spring are the moving parts inside a solenoid valve. The coil energizes the plunger, which then opens or closes the valve. The spring helps return the plunger to its original position. These components endure constant friction and stress.

Manufacturers typically make plungers and springs from stainless steel. Stainless steel offers excellent corrosion resistance, especially in water environments. It also provides the necessary strength and resilience for repeated operation. A high-quality stainless steel plunger moves smoothly and resists wear. A robust spring maintains its tension over millions of cycles. These materials ensure reliable and consistent valve action.

Orifice Design and Flow Path for Brass Solenoid Valves

The orifice is the opening inside the valve that controls fluid flow. Its design significantly impacts the valve’s performance, including flow rate and pressure drop.

| Orifice Size | Restriction | Flow Rate | Velocity Jet | Pressure Drop Across Valve |

|---|---|---|---|---|

| Small | High | Lower | Higher | Higher |

| Large | Lower | Higher | Lower | Lower |

Understanding how the orifice works helps you choose the right valve.

- Continuity Principle: This principle states that the same mass flow entering an orifice must leave it. When fluid passes through a smaller opening, its velocity increases in that section.

- Bernoulli’s Principle: This principle explains that as velocity increases through the orifice, the static pressure decreases. The valve ‘uses up’ some pressure to push fluid through the restriction. This results in a pressure drop (ΔP).

The orifice diameter is also crucial for the valve’s flow capacity, known as its Cv value.

- Definition: Cv is a metric representing the flow capacity. It tells you how many U.S. gallons per minute of water at 60 °F will flow through a valve with a 1 psi pressure drop.

- Orifice’s Role: The orifice diameter is the primary determinant of a solenoid valve’s Cv. A larger orifice almost always results in a higher Cv, assuming similar valve architectures.

- Impact of Cv Selection: Choosing too low a Cv can starve downstream pressure or cap flow. Too high a Cv can lead to overshooting, loss of fine control, and unnecessary cost or weight.

Different valve types use orifices in different ways:

- Direct-Acting Valves: These valves have relatively small orifices. The coil must directly overcome line pressure to unseat the seal. This design allows operation at zero differential pressure but results in a lower Cv.

- Pilot-Operated Valves: These valves use a tiny pilot orifice to manipulate pressure. This pressure then moves a diaphragm or piston off a larger main orifice. This design allows for larger orifices and higher Cv. However, it typically requires a minimum differential pressure to function properly.

A well-designed flow path minimizes turbulence and maximizes efficiency. This contributes to the overall durability and performance of the Brass Solenoid Valve.

Coil and Electrical Durability in Brass Solenoid Valves for Water Environments

The coil is the heart of a solenoid valve. It creates the magnetic field that operates the valve. Its durability is crucial, especially in water environments.

Encapsulation Methods for Brass Solenoid Valve Coils

A coil needs protection from moisture, dust, and physical damage. Manufacturers use different encapsulation methods to achieve this. These methods include:

- Sealed in epoxy

- Encased in plastic

- Encased in metal

One common method involves specialized epoxy and thermoplastic overmolding processes. These create highly durable, weather-resistant, and waterproof coils. For example, plastic overmolding seals the coil, often providing an IP65 rating. This rating means the coil resists water and dust. Potting is another method where manufacturers fill air gaps around the coil with a material like epoxy. This creates effective protection against water ingress. Encapsulated coils are coated in a resin, like epoxy, which covers the wire. This coating protects the wires against moisture and other types of damage, making them more efficient at moisture protection.

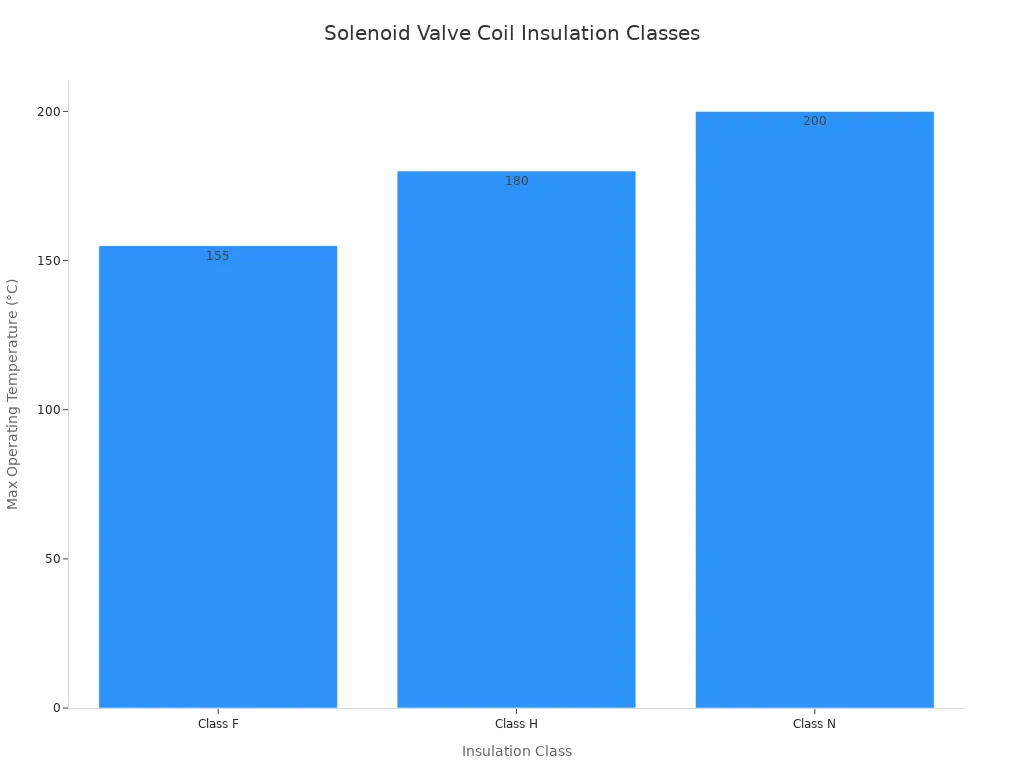

Insulation Class and Temperature Ratings for Brass Solenoid Valves

Coil insulation protects the wire windings from heat. Different insulation classes handle different maximum operating temperatures. This is very important for coil longevity.

| Insulation Class | Maximum Operating Temperature |

|---|---|

| Class F | 155°C |

| Class H | 180°C |

| Class N | 200°C |

Exceeding these temperature ratings significantly impacts a coil’s lifespan. If the wire temperature approaches or exceeds 200°C, it can cause damage or burnout. This directly shortens the coil’s lifespan.

Voltage and Power Consumption Impact on Brass Solenoid Valve Coils

Solenoid valve coils naturally generate heat when they operate. The amount of heat produced directly relates to the wattage the valve needs. Higher wattage leads to greater heat generation. This heat can cause reliability issues. It can also be problematic in enclosed spaces.

There is a direct link between a solenoid valve’s power consumption and the heat it generates. Part of the energy the valve uses turns into heat. Too much heat can damage the valve and shorten its life. Conversely, solenoid valves with lower power consumption produce less heat. This helps increase reliability and extends operational life. If the coil becomes too hot, it can overheat and burn out. This directly impacts the lifespan of the Brass Solenoid Valve.

Operational Factors Influencing Brass Solenoid Valve Lifespan

A solenoid valve’s lifespan does not just depend on its build. How people use it also plays a big role. Several operational factors directly affect how long a Brass Solenoid Valve will last in a water system.

Pressure and Temperature Ratings for Brass Solenoid Valves

Matching a valve’s pressure and temperature ratings to the system’s conditions is very important. Brass solenoid valves can handle high pressures, sometimes up to 140 bar (2030 psi). However, residential water systems usually have lower pressures. Mains water typically ranges from 2 to 4 bar. Some areas might see pressures over 10 bar. For these common residential uses, WRAS approved solenoid valves rated for 10 bar are usually enough. Exceeding these ratings can cause leaks or even valve failure. Similarly, operating a valve outside its specified temperature range can damage seals and internal components.

Duty Cycle: Continuous vs. Intermittent Operation of Brass Solenoid Valves

The duty cycle describes how often and how long a valve stays open. Continuous duty means the valve remains energized for long periods. This generates heat. During continuous duty operation, a solenoid’s surface temperature can reach up to 120°C. Three factors influence the coil temperature: the fluid’s temperature, the surrounding air temperature, and the heat the coil itself makes. Standard solenoid valves often have continuous duty coils with proper insulation. It is normal for the coil to get hot after being on for a while. However, smoke or a burning smell means the coil is too hot. People should disconnect power immediately if this happens. For valves running continuously, especially in non-ideal conditions, a holding voltage circuit is highly recommended. This prevents damage to parts not in the solenoid assembly. High-pressure valves always need a holding voltage circuit or other cooling methods.

Water Quality Considerations for Brass Solenoid Valves

The quality of the water flowing through the valve also impacts its durability. Water with high levels of sediment, minerals, or corrosive chemicals can cause problems. Sediment can clog the orifice or wear down internal parts. Hard water can lead to mineral buildup, which affects valve operation. Corrosive chemicals can degrade brass and sealing materials over time. Regular maintenance and proper filtration can help extend the life of a Brass Solenoid Valve in systems with poor water quality.

Key Specifications for Durable Brass Solenoid Valves in 2025

Choosing a durable valve involves more than just looking at its physical build. You also need to consider external factors. These include industry standards, manufacturer support, and how easy it is to maintain the valve.

Certifications and Standards for Brass Solenoid Valves

Certifications prove a valve meets specific quality and safety benchmarks. They assure users of a product’s reliability. For water systems, especially those handling drinking water, certifications are critical.

| Certification | Focus Area | Applicable Regions | Key Benefits |

|---|---|---|---|

| CE | Health, safety, and environment | Europe | Legal compliance for EU markets |

| RoHS 3 | Restriction of hazardous substances | Europe and globally for exports | Environmentally friendly |

| NSF | Food & water safety | U.S. & International | Safe for use in food and drinking water applications |

For valves dispensing potable water in North America, NSF/ANSI61 certification is a must. This standard involves strict chemical leaching tests. It ensures the product does not contaminate the water it touches. In Europe, a valve needs CE marking and RoHS/RoHS 2 compliance. NSF/ANSI 61 certification also guarantees safety for drinking water and human consumption. This ensures water safety. Look for valves with:

- Lead-Free Brass Construction: This ensures safety for potable water and meets health regulations.

- UL and NSF Certifications: These guarantee reliable performance in critical water systems.

Manufacturer Reputation and Warranty for Brass Solenoid Valves

A manufacturer’s reputation often reflects the quality of its products. Reputable companies invest in research, development, and rigorous testing. They stand behind their valves. A strong warranty also signals a manufacturer’s confidence in their product’s durability. Some high-durability valves offer a 24-month warranty. Others might provide a warranty for 5000 hours of operation. Many manufacturers offer a comprehensive one-year warranty on all their valves. A good warranty protects your investment and gives you peace of mind.

Ease of Maintenance and Replacement Parts for Brass Solenoid Valves

Even the most durable valve eventually needs maintenance. Easy access to replacement parts significantly extends a valve’s lifespan. Manufacturers who offer readily available spare parts make maintenance simpler. This reduces downtime and overall operating costs. Look for valves with modular designs. These designs allow for easy replacement of coils, seals, or plungers. This ensures your water system remains operational for years to come.

To get the most durable solenoid valves for water systems in 2025, people should look for specific features. Prioritize models with strong forged brass bodies. They also need EPDM or Viton seals and stainless steel parts inside. Fully encapsulated coils are also very important.

Always match the valve’s operational details to what your system needs. Also, consider the manufacturer’s reputation for long-lasting reliability. This helps ensure your water system works well for many years.

FAQ

What makes forged brass more durable than cast brass for solenoid valves?

Forged brass is denser and stronger. Manufacturers press it into shape, which removes tiny air pockets. This process makes it better at handling high pressure and resisting leaks. Cast brass has pores, making it less durable over time.

Which sealing material is best for water systems: EPDM or Viton?

EPDM works well for most standard water applications. It resists ozone and aging. Viton is better for water systems with oils, fuels, or aggressive chemicals. Always match the seal material to the specific fluid for best performance.

How does coil encapsulation protect a solenoid valve?

Coil encapsulation protects the coil from moisture, dust, and physical damage. Methods like epoxy sealing or plastic overmolding make the coil weather-resistant and waterproof. This prevents water from entering and damaging the electrical components, extending the valve’s life.

Why are certifications important for brass solenoid valves in water systems?

Certifications like NSF/ANSI 61 or CE marking ensure a valve meets specific quality and safety standards. For drinking water, NSF/ANSI 61 guarantees the valve does not contaminate the water. These certifications confirm reliability and compliance.

How does water quality affect a brass solenoid valve’s lifespan?

Poor water quality can shorten a valve’s life. Sediment can clog the valve or wear down parts. Hard water causes mineral buildup, affecting operation. Corrosive chemicals can degrade brass and seals. Proper filtration helps extend the valve’s durability.