A 2-way valve provides simple on/off fluid control and isolation. A 3-way valve excels at diverting flow, mixing fluids, or controlling single-acting cylinders. For precise control of double-acting pneumatic cylinders and complex pneumatic systems, a 5-way valve is ideal. These devices are crucial in many applications. For instance, a brass solenoid valve often works well in water systems. A pilot-operated solenoid valve handles higher pressures effectively. An automation solenoid valve improves system efficiency. What industries use solenoid valves? Many sectors depend on them. How to choose a solenoid valve? This important decision depends on the specific job.

Key Takeaways

- A 2-way solenoid valve is best for simple on/off control of fluids. It acts like a switch to start or stop flow.

- A 3-way solenoid valve can change where a fluid goes or mix different fluids. It also controls cylinders that move in one direction.

- A 5-way solenoid valve is perfect for controlling cylinders that move in two directions. It gives very exact control over their movement.

- Choosing the right valve depends on what you need it to do. Consider the fluid, pressure, and how much control you need.

- The materials of a valve are important. They must work well with the fluid and the environment to last a long time.

2-Way Solenoid Valves: The Foundation of On/Off Control

How a 2-Way Solenoid Valve Operates

A 2-way solenoid valve controls fluid flow by opening or closing a single path. It has two ports: an inlet and an outlet. An electrical current energizes a coil, creating a magnetic field. This field moves a plunger or armature, which then opens or closes the valve’s orifice. When the valve is open, fluid flows through. When it is closed, fluid stops. This simple mechanism provides reliable on/off control for various liquids and gases.

Ideal Applications for 2-Way Solenoid Valves

These valves are essential for many industrial tasks. They control the flow of fluids in industrial processes. Manufacturers use them for automating machinery. They manage water and air in HVAC systems. Two-way valves also operate pneumatic and hydraulic systems. Furthermore, they ensure safety in emergency shutdown systems. Their straightforward design makes them suitable for basic fluid management.

Advantages of Using 2-Way Solenoid Valves

Two-way solenoid valves offer several benefits. They provide rapid on/off switching capabilities. This quick action is crucial in many automated systems. For instance, response times for pneumatic solenoid valves typically range from 5 to 100 milliseconds. Response times below 15ms are considered rapid for industrial pneumatic systems. Sub-5ms response times characterize servo-valves, while times exceeding 50ms are often too slow for precise timing. Their compact design allows for installation in space-constrained areas. They also show high reliability during repetitive operations. These valves are energy-efficient due to their low power consumption. They handle various media, including liquids, gases, and steam, making them highly versatile.

Practical Examples of 2-Way Solenoid Valve Use

Two-way valves find widespread use across many industries. They perform essential on/off functions in everyday applications. For example, automatic irrigation systems rely on these valves. They precisely control water flow to different zones. This ensures efficient watering of lawns and gardens. These systems often operate on a schedule, turning water on and off as needed.

In household appliances, 2-way valves are common. Washing machines use them to fill with water at specific times. Dishwashers also employ them for water intake during wash cycles. Coffee makers utilize these valves to dispense hot water for brewing. These applications demonstrate their reliability in repetitive tasks. They ensure appliances function correctly and safely.

Industrial processes also benefit greatly from 2-way valves. Chemical plants use them for accurate dosing of liquids into mixing tanks. They control the flow of cooling water in manufacturing equipment, preventing overheating. Air compressors often feature 2-way valves to manage air supply to various tools. This ensures proper operation of pneumatic systems on production lines.

Furthermore, safety systems frequently incorporate 2-way valves. They act as emergency shut-off devices for fuel lines in power generators or industrial furnaces. This quickly stops the flow of flammable liquids or gases in critical situations, preventing accidents. Medical devices also use a specialized 2-way solenoid valve for precise fluid control. They manage the flow of medications or diagnostic reagents in laboratory equipment. These examples highlight the versatility and importance of 2-way valves in modern technology, from simple household items to complex industrial machinery.

3-Way Solenoid Valves: Versatility in Flow Diversion

How a 3-Way Solenoid Valve Operates

A 3-way valve controls fluid flow using three ports. It operates in two distinct positions. In its first position, the valve connects one inlet port to one outlet port, while keeping the third port closed. When the valve shifts to its second position, it connects the inlet port to the previously closed port, blocking the first outlet. This action allows the valve to effectively divert fluid from one path to another or to select between two different fluid sources. The internal design dictates its specific function.

- L-port valves primarily divert fluid flow to one direction at a time.

- T-port valves commonly mix different fluid compositions. They can also divert fluids to two destinations simultaneously. This design makes the 3-way valve highly adaptable for various fluid control tasks.

Key Applications for 3-Way Solenoid Valves

These valves are ideal for tasks that involve redirecting or combining fluids. They frequently control single-acting pneumatic cylinders. For instance, they push a cylinder rod out by sending air to one side. Then, they pull it back by exhausting that air and allowing a spring to return the rod. In industrial processes, a 3-way solenoid valve can switch a fluid stream between two different processing tanks. They also mix two separate liquids to create a new solution. This is common in chemical blending or in dispensing systems for beverages.

Benefits of 3-Way Solenoid Valves

3-way valves offer several important advantages. They provide precise control over the direction of fluid flow. This leads to very efficient operation in automated machinery. Their ability to perform multiple functions, such as diverting, mixing, or controlling cylinders, often means fewer components are needed. This simplifies the overall system design and reduces installation complexity. They are also known for their reliability during continuous use. This makes them a cost-effective and robust choice for many fluid management challenges.

Practical Examples of 3-Way Solenoid Valve Use

Three-way valves find use in many practical situations. They manage fluid flow effectively. For example, these valves are crucial for controlling single-acting pneumatic cylinders. They also manage other pneumatic actuators. A 3/2-way pneumatic valve regulates airflow. It has an inlet, an outlet, and an exhaust port. When the valve is active, air flows into the cylinder. This causes the actuator to extend. When the valve is inactive, it blocks airflow. The actuator then retracts. A spring often drives this retraction. This simple control makes them ideal for many automated tasks.

These valves also perform blow-off tasks. They handle pressure release operations. Vacuum applications benefit from their design. These valves suit simpler pneumatic systems well.

Beyond pneumatics, consider beverage dispensers. A 3-way valve can switch between water and syrup. This creates a mixed drink. In chemical processing, they divert a chemical stream. This sends it to different reaction vessels. HVAC systems use them to direct hot or cold water. This controls room temperature. These examples show the valve’s versatility. It provides precise control in diverse environments.

Tip: 3/2-way pneumatic valves are particularly well-suited for simpler pneumatic systems, such as those involving single-acting pneumatic cylinders, due to their ability to manage an inlet, an outlet, and an exhaust port.

5-Way Solenoid Valves: Mastering Double-Acting Actuators

How a 5-Way Solenoid Valve Operates

A 5-way valve precisely controls double-acting pneumatic cylinders. It features five ports. One port serves as the pressure inlet. Two ports connect to the cylinder, one for each side of the piston. The remaining two ports act as exhaust outlets. This configuration allows the valve to direct pressurized air to one side of the cylinder while simultaneously exhausting air from the other side. When the valve shifts position, it reverses the airflow. This action extends or retracts the cylinder rod. This design provides full control over the cylinder’s movement.

Primary Applications for 5-Way Solenoid Valves

These valves are essential for automating machinery. They primarily function as directional control valves for double-acting pneumatic actuators. Industries widely use them for precise motion control. The semiconductor industry relies on them for delicate processes. The automotive industry uses them in assembly lines. Packaging machinery benefits from their accurate control. The medical industry employs them in various devices. Specialty machine industries and machine tool industries also depend on these valves for their operations.

Advantages of 5-Way Solenoid Valves

Five-way valves offer significant benefits for pneumatic systems. They provide improved response times. The inclusion of an extra exhaust port allows for quicker venting of air. This faster venting directly contributes to overall system efficiency. These valves are ideal for rapid and precise motion control. Applications demanding quick and accurate movements, such as in robotics or packaging machinery, greatly benefit from this capability. A 5-way solenoid valve ensures efficient and reliable operation in complex automated systems.

Practical Examples of 5-Way Solenoid Valve Use

Five-way valves are indispensable in many automated systems. They provide precise control for various industrial tasks. These valves are crucial for actuating double-acting pneumatic cylinders. This means they can extend and retract a cylinder rod with controlled force.

Consider high-speed manufacturing environments.

- Packaging lines use 5-way valves for rapid sorting and sealing operations.

- Assembly lines rely on them for quick component placement.

- Sorting systems benefit from their fast actuation in diverting products.

These applications demand quick and reliable movement. The valves’ design allows for rapid air pressure exhaust. This contributes to faster cycle times.

In precision-focused industries, 5-way valves are equally vital.

- Robotics employs them for delicate and accurate arm movements.

- Precision machining uses them to control tools with high accuracy.

Their separate exhaust paths offer superior control over actuation speed in both directions. This allows for fine-tuning of cylinder movement. For example, automated machining processes use 5/3-way valves for indexing workpieces. This ensures parts are positioned precisely during production. These valves ensure efficient and reliable operation in complex automated systems. They are a cornerstone of modern industrial automation.

Understanding Solenoid Valve Configurations and Types

Normally Open vs. Normally Closed Solenoid Valves

Solenoid valves come in two main default states: normally closed (NC) and normally open (NO). A normally closed valve remains shut when de-energized. It opens only when power is applied. Conversely, a normally open valve stays open without power. It closes when electricity flows through it. This difference is crucial for safety and operational needs.

| Feature | Normally Closed (NC) Solenoid Valve | Normally Open (NO) Solenoid Valve |

|---|---|---|

| Default State | Closed (de-energized) | Open (de-energized) |

| Power Application | Opens when power is applied | Closes when power is applied |

| Power Consumption | Consumes power when open | Consumes power when closed |

| Fail-Safe Behavior | Closes on power failure | Opens on power failure (continuous flow) |

| Typical Use Case | Stop flow when power fails | Maintain flow when power fails |

Normally open valves are excellent for applications needing continuous flow by default. They ensure flow even during a power outage. For example, they are vital in:

- Emergency Cooling Systems: They prevent equipment overheating during power failures.

- Ventilation Systems: They maintain airflow during electrical outages.

- Fire Suppression Lines: They ensure fire extinguishing agents are available.

- Process Purging or Draining: They allow gravity-fed draining when a system is idle.

- Bypass or Drain Lines: They maintain a default flow path.

Direct-Acting, Pilot-Operated, and Semi-Direct Solenoid Valves

Solenoid valves also differ in their actuation method. Direct-acting valves use the solenoid’s magnetic force to directly open or close the main orifice. They are simple and work well with low flow rates and pressures. Pilot-operated valves use a small pilot solenoid to control a larger main valve. System pressure assists in opening or closing the main valve. This design handles higher pressures and flow rates. Semi-direct valves combine aspects of both. They use a pilot to assist the main valve, but they can also operate from zero pressure.

Port and Position Terminology for Solenoid Valves

Understanding port and position terminology is key to selecting the right solenoid valve. “Ports” are the connections where fluid enters or exits the valve. “Positions” refer to the number of stable states the valve can achieve. For instance, a 2-way valve has two ports and two positions (open or closed). A 3-way valve has three ports and two or three positions.

Double solenoid valves offer unique control. They have two coils. Energizing each coil moves the valve to a specific position. The valve retains its last position even after power loss. This is useful for complex control scenarios. For example, crop spraying requires precise fluid flow. Double solenoids help maintain consistent spray patterns. The choice between 3-port and 5-port valves depends on the control level needed. A 3-port valve supplies and vents one side of a cylinder. A 5-port valve supplies and vents both sides, offering more control.

Critical Factors for Solenoid Valve Selection

Choosing the correct solenoid valve is vital for any system. Many factors influence this decision. Engineers must consider the fluid, operating conditions, and electrical needs. Careful selection ensures efficiency, reliability, and safety.

Fluid Compatibility and Operating Conditions

The type of fluid a solenoid valve handles is a primary concern. The valve’s materials must not react with the fluid. For example, the fluid’s chemical composition matters greatly. Acids, bases, solvents, or oxidizing agents can corrode valve parts. Strong acids can damage brass and some stainless steels. Solvents can swell or dissolve certain rubber seals.

Temperature also plays a big role. High temperatures speed up chemical reactions between the fluid and valve materials. This increases corrosion. High heat can also make rubber seals lose their elasticity. This leads to seal failure. Low temperatures can make materials brittle. This reduces their ability to resist impact. Pressure is another key factor. High pressure puts stress on valve parts. This requires stronger materials and better seals. A valve not designed for the fluid’s pressure can leak or break.

Different fluids need different valve materials. For clean water, brass or stainless steel valves usually work well. If water has impurities like chlorine, stainless steel is often better than brass. Air is generally not corrosive. Most solenoid valves work fine with air. Pneumatic solenoid valves are made specifically for air in factories. For oils, the valve seals must resist swelling. Nitrile rubber is a common choice for oil-compatible seals. Aggressive chemicals need strong materials. PTFE-lined stainless steel is an example. High-pressure pneumatic solenoid valves can control chemical flow.

Ignoring fluid compatibility creates risks. Corrosion can cause leaks. This is dangerous with toxic or flammable fluids. Leaks also waste product and harm the environment. Bad compatibility can also cause seal failure. This leads to pressure loss and less efficient systems. Valve problems due to wrong materials can stop production. This costs money and time.

Pressure, Flow Rate, and Orifice Size for Solenoid Valves

Pressure, flow rate, and orifice size are critical for valve performance. The orifice is the opening inside the valve. Its size directly affects how much fluid flows and how much pressure drops. A smaller orifice restricts flow. This creates a faster fluid jet and a larger pressure drop across the valve. A larger orifice allows more flow with less restriction. This results in a lower pressure drop.

The flow coefficient (Cv) measures a valve’s liquid flow capacity. It tells how many U.S. gallons of water flow per minute at 60°F with a 1 psi pressure drop. The orifice diameter mainly determines a solenoid valve’s Cv. Choosing the right Cv is essential. Engineers calculate it from the target flow, pressure difference, and fluid type. An undersized Cv can limit downstream pressure or flow. An oversized Cv can cause poor control and cost more money.

An undersized orifice restricts flow too much. This causes high pressure drops and increases energy costs. It also leads to high fluid speed, turbulence, and noise. Over time, this can damage the valve. In critical systems, it can even be dangerous. An oversized orifice reduces pressure drop. However, it can cause poor control and system instability. It might also lead to chattering in check valves and faster wear.

When selecting a valve, determine the needed flow rate and acceptable pressure drop. Use the Cv to ensure the valve handles the required flow. Choose a Cv slightly higher than the maximum needed flow. Always check the datasheet for orifice diameter or Cv. Do not just rely on pipe size. Pipe size does not show the internal orifice size. Consider the fluid type. For example, liquids can cause cavitation. Gases can have choked flow. Fluids with particles can clog the valve. Account for system changes. Ensure the orifice size prevents issues like water hammer. A slightly smaller orifice can offer better control. It can also reduce pressure spikes. Choose valve orifices that minimize pressure loss for energy efficiency.

| Feature | Direct-Acting Valves | Pilot-Operated Valves |

|---|---|---|

| Orifice Size | Relatively small | Larger |

| Cv (Flow Coefficient) | Lower | Higher |

| Pressure Requirement | Works at zero differential pressure (no minimum ΔP) | Requires a minimum differential pressure (ΔP) to function |

| Opening Mechanism | Coil’s magnetic force directly lifts plunger | Coil opens a tiny pilot orifice, creating pressure imbalance to move diaphragm/piston |

| Application | Low-pressure sources, gravity tanks, vacuum | Applications with adequate ΔP and higher flow requirements |

Electrical Requirements and Power Consumption

Solenoid valves need electrical power to operate. Engineers must match the valve’s electrical specifications to the system’s power supply. Key electrical factors include voltage, current, and power consumption. Valves are available for various AC and DC voltages. Using the wrong voltage can damage the coil or prevent proper operation.

The power consumption of a solenoid valve affects energy costs. It also impacts the size of the power supply needed. Some valves use more power to open or close. Others use less power to hold their position. Continuous duty valves can remain energized for long periods without overheating. Intermittent duty valves can only be energized for short times. Choosing the right duty cycle prevents coil burnout.

Environmental Considerations and Material Selection

The environment where a valve operates significantly impacts its performance and lifespan. Engineers must carefully consider external factors. These factors include temperature, humidity, and exposure to corrosive substances. The valve’s materials must withstand these conditions.

For example, high temperatures can degrade certain materials. Corrosive chemicals in the air or fluid can cause rust or material breakdown. Therefore, selecting the right material for the valve body and seals is crucial.

- Cost vs. Performance: Cheaper plastic materials exist. However, they generally do not perform as well or last as long as metal valves. High-quality alloys cost more initially. They offer better long-term value.

- Corrosion and Rust Resistance: Stainless steel or titanium are superior choices for chemical or acid resistance.

- Mechanical Properties: The valve material must withstand high pressure or high temperature. Carbon steel and stainless steel provide improved strength. They also offer significantly higher resistance to thermal stress compared to bronze or brass. In extreme temperatures, Inconel material may be necessary.

Stainless steel is a premium choice for high-temperature environments. It offers excellent corrosion resistance. It also has a high melting point. This makes it suitable for aggressive media like chemicals or superheated steam. Brass is a cost-effective and robust alloy. It performs well in hot water and oil applications. It also offers good thermal conductivity. The choice between these materials balances performance needs, budget, and the fluid’s chemical properties.

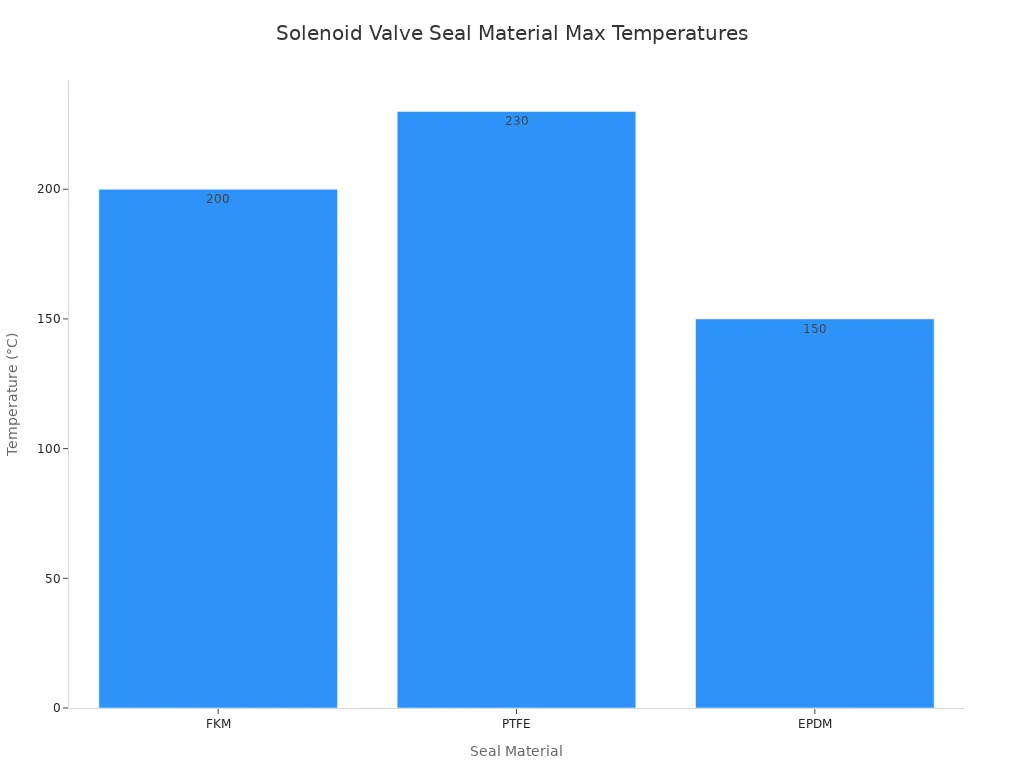

Seal materials are equally important. They prevent leaks and maintain pressure. Different seal materials suit different operating conditions.

| Seal Material | Common Name | Typical Max Temperature | Best For |

|---|---|---|---|

| FKM | Viton® | ~200°C | Hot oils, fuels, and many industrial chemicals. |

| PTFE | Teflon® | ~230°C | Aggressive media, steam, and food-grade uses. |

| EPDM | EPDM | ~150°C | Hot water, steam, and glycol-based fluids. |

- FKM (Viton®): This material is ideal for systems handling hot hydraulic oils or engine fuels. It shows excellent resistance to hydrocarbons.

- PTFE (Teflon®): This is a powerful choice for chemical resistance. It provides low-friction surfaces. It handles aggressive substances, including pure, high-temperature steam.

- EPDM: This material shines in applications involving water or steam. Examples include industrial boilers, district heating systems, or autoclaves. However, it performs poorly with oils and solvents.

Maintenance and Longevity of Solenoid Valves

Proper maintenance significantly extends the life of valves. Regular checks and timely replacements prevent unexpected failures. Several factors influence how long a valve lasts. These include the quality of the fluid, the operating conditions, and correct installation.

Fluid quality directly affects valve components. Contaminants can cause wear or blockages. Clean fluids reduce stress on internal parts. Operating conditions, such as extreme temperatures or pressures, can accelerate wear. Valves designed for specific conditions perform better and last longer. Correct installation ensures the valve operates as intended. Improper installation can lead to leaks or premature failure.

Regular maintenance includes inspecting seals for wear. It also involves checking for corrosion on valve bodies. Cleaning internal components prevents buildup. Replacing worn parts proactively avoids system downtime. These actions ensure the valve continues to function reliably. SENYA focuses on producing high-quality valves. They use advanced processing and precision testing. This ensures consistency and stability in their products. Their commitment to quality helps ensure long-lasting performance in various applications.

Comparing Solenoid Valve Types for Optimal Performance

Choosing the right valve is crucial for any fluid control system. Different solenoid valve types offer distinct advantages. Engineers must understand these differences to ensure optimal performance. This section compares 2-way, 3-way, and 5-way valves. It highlights their control capabilities, cost implications, and ideal applications.

Port Configuration and Control Capabilities

The number of ports and positions defines a valve’s function. Each configuration offers unique control capabilities. This table summarizes the key differences:

| Valve Type | Ports | Positions | Control Capabilities / Applications |

|---|---|---|---|

| 2-way (2/2) | 2 (inlet, outlet) | 2 (open, closed) | Standard on/off control for water, air. Can be normally closed or normally open. |

| 3-way (3/2) | 3 | 2 (open, closed) | Diverts flow to one of two ports (e.g., automotive vegetable oil conversions). Ideal for pneumatic spring return actuators or cylinder control in normally closed function. |

| 5-way (5/2) Spring Return | 5 | 2 (open, closed) | Pneumatic applications (air), typically with 3 ports on one side (inlet, exhaust) and 2 outlet ports for cylinder/actuator. Energized opens actuator, de-energized closes. |

| 5-way (5/2) Double Acting | 5 | 2 (open, closed) | Pneumatic applications (air), with 2 coils. Coil 1 energizes to open actuator/cylinder, Coil 2 energizes to close. Stays in last position when both coils are de-energized. |

A 2-way valve provides simple on/off control. It acts like a switch for fluid flow. A 3-way valve offers more versatility. It can divert fluid between two paths or control single-acting cylinders. Five-way valves provide the most complex control. They precisely manage double-acting pneumatic cylinders. This allows for detailed control over actuator movement.

Cost-Effectiveness and System Complexity

Selecting the correct valve involves more than just port count. Engineers consider system safety, efficiency, and long-term cost. Each valve type impacts these factors differently.

- 2-Way Valves: These valves are generally the simplest and most cost-effective. They perform straightforward on/off flow control. Their simple design also means less complexity in the overall system.

- 3-Way Valves: These valves offer a cost-effective solution for managing fluid flow. They handle various applications like mixing, diverting, or automating operations efficiently. They add a moderate level of complexity compared to 2-way valves.

- 5-Way Valves: These valves are designed for precise control of double-acting cylinders. They are common in advanced automation systems. Their increased functionality often means a higher initial cost and more complex system integration.

System complexity increases with the valve’s capabilities. Simple on/off tasks require less complex systems. Precise control of actuators demands more sophisticated valve types and control logic.

When to Choose a 2-Way Solenoid Valve

A 2-way solenoid valve is the optimal choice for specific fluid control tasks. Its design excels in straightforward applications. Consider these criteria when selecting a 2-way valve:

- Single Line On/Off Control: Choose a 2-way valve for basic flow management. It provides a clear ‘open’ or ‘closed’ state. It does not divert or mix fluids. It acts as a simple switch for fluid flow.

- Positive Shut-Off or Isolation: This valve is ideal when complete stoppage of fluid movement is critical. It creates a tight, leak-free seal. This prevents backflow or isolates sections for maintenance.

- Energy Efficiency: A 2-way valve is efficient when it remains in one state for long periods. It consumes power only when changing or maintaining an energized state.

- Compact Footprint: Its simple design with two ports makes it suitable for space-constrained systems. This allows for easier integration and flexible placement. It also reduces system size.

- Non-Diverting Flow Path Scenarios: This valve is best for applications that do not require fluid diversion or mixing. It focuses solely on controlling flow in a single path.

Beyond function, material compatibility and ratings are also important.

- Fluid Compatibility: The valve’s materials must be compatible with the fluid’s chemical properties and temperature. This includes the housing, plunger, spring, and seals. For example, brass works for neutral liquids. Stainless steel suits chemicals. NBR, EPDM, or FKM are common seal materials.

- Pressure and Temperature Ratings: The valve must withstand the operating pressure and temperature of the fluid system.

- Material Construction for Durability: The valve body, seals, and internal components need durable materials. These materials must endure the fluid and environment. This ensures longevity and reliable performance. Stainless steel offers excellent corrosion resistance.

When to Choose a 3-Way Solenoid Valve

Engineers select a 3-way valve for tasks needing fluid diversion or mixing. This valve also controls single-acting cylinders effectively. Consider these situations when a 3-way valve is the best choice:

- Diverting Flow: The system needs to send fluid to one of two different paths. For example, a process might fill two separate tanks from a single source. A 3-way valve directs the fluid to Tank A or Tank B.

- Mixing Fluids: Two different fluids combine into one stream. A 3-way valve can manage the flow of each fluid. This creates a precise mixture.

- Controlling Single-Acting Cylinders: These cylinders extend with air pressure and retract with a spring. A 3-way valve supplies air to extend the cylinder. It then exhausts the air to allow the spring to retract it. This provides simple, reliable motion control.

- Pressure Release or Venting: The system needs to release pressure from a line or vent a chamber. A 3-way valve can open a path to exhaust while closing the inlet.

- Actuating Pilot Valves: A larger valve might need a smaller pilot valve to operate. A 3-way valve can control the pilot signal. This then controls the main valve.

A 3-way valve offers a compact solution for these functions. It reduces the need for multiple 2-way valves. This simplifies plumbing and control logic. Its design makes it versatile for many industrial and commercial applications.

When to Choose a 5-Way Solenoid Valve

A 5-way valve is the ideal choice for precise control of double-acting pneumatic cylinders. These cylinders require air pressure to extend and retract. They do not use springs for return. This valve provides full control over both movements. Consider these points when selecting a 5-way valve:

- Controlling Double-Acting Cylinders: This is the primary application. The valve directs pressurized air to one side of the cylinder. It simultaneously exhausts air from the other side. This pushes the piston in one direction. Then, the valve reverses the airflow. This pushes the piston in the opposite direction.

- Precise Actuator Movement: Applications demand exact control over cylinder speed and position. A 5-way valve allows fine-tuning of both extension and retraction. This is crucial in robotics or automated assembly.

- Complex Pneumatic Systems: Systems with multiple double-acting actuators benefit from the clear control a 5-way valve offers. It simplifies the pneumatic circuit compared to using multiple 3-way valves.

- Faster Cycle Times: The separate exhaust ports allow for quicker venting of air. This leads to faster cylinder movement. High-speed packaging or sorting machines often use these valves.

- Safety and Reliability: In critical automation tasks, a 5-way solenoid valve ensures reliable and repeatable motion. This contributes to overall system safety and efficiency.

Choosing a 5-way valve ensures efficient and accurate operation for double-acting pneumatic actuators. It provides the necessary control for advanced automation.

Two-way solenoid valves are the go-to for straightforward fluid isolation and flow control tasks. Three-way solenoid valves offer excellent solutions for diverting paths or controlling single-acting cylinders. Five-way solenoid valves are indispensable for precise and efficient control of double-acting pneumatic actuators. Selecting the correct solenoid valve type is crucial for system efficiency, reliability, and cost-effectiveness. This directly impacts application success. Key factors like coil design, plunger characteristics, valve seat and seal, and valve body design all determine a valve’s performance. Choosing the right valve, even if it has a higher initial cost, leads to fewer breakdowns and a longer service life. This makes it a wiser investment for overall system efficiency and reliability.

FAQ

What is the main difference between 2-way, 3-way, and 5-way solenoid valves?

A 2-way valve controls simple on/off flow. A 3-way valve diverts fluid or controls single-acting cylinders. A 5-way valve precisely manages double-acting pneumatic cylinders. Each type serves specific fluid control needs.

Can a 2-way solenoid valve control a double-acting cylinder?

No, a 2-way valve cannot control a double-acting cylinder. Double-acting cylinders need two separate air paths for extension and retraction. A 5-way valve provides this necessary control.

What does “normally closed” mean for a solenoid valve?

A normally closed valve stays shut when it has no power. It opens only when electricity flows through it. This design ensures fluid stops if power fails.

Why is material selection important for solenoid valves?

Material selection ensures the valve works correctly and lasts long. The valve’s parts must not react with the fluid. They must also withstand operating temperature and pressure. This prevents leaks and damage. 🛠️