Solenoid Valves are essential for achieving unparalleled precision and efficiency in industrial automation. They enable rapid, accurate control of air and gas flow, directly optimizing operational performance. The global solenoid valves market is projected to reach USD 5.10 billion in 2024, underscoring their significant impact. These pneumatic solenoid valves play a fundamental role in transforming industrial processes for enhanced productivity and reliability. Solenoid valves for industry are truly versatile, demonstrating the top uses of solenoid valves in industry across many sectors. You might ask, which industries use pneumatic solenoid valves? Many different fields benefit from the industrial uses of pneumatic solenoid valves.

Key Takeaways

- Solenoid valves are important devices. They control how liquids or gases flow in machines. This helps make industrial tasks work better.

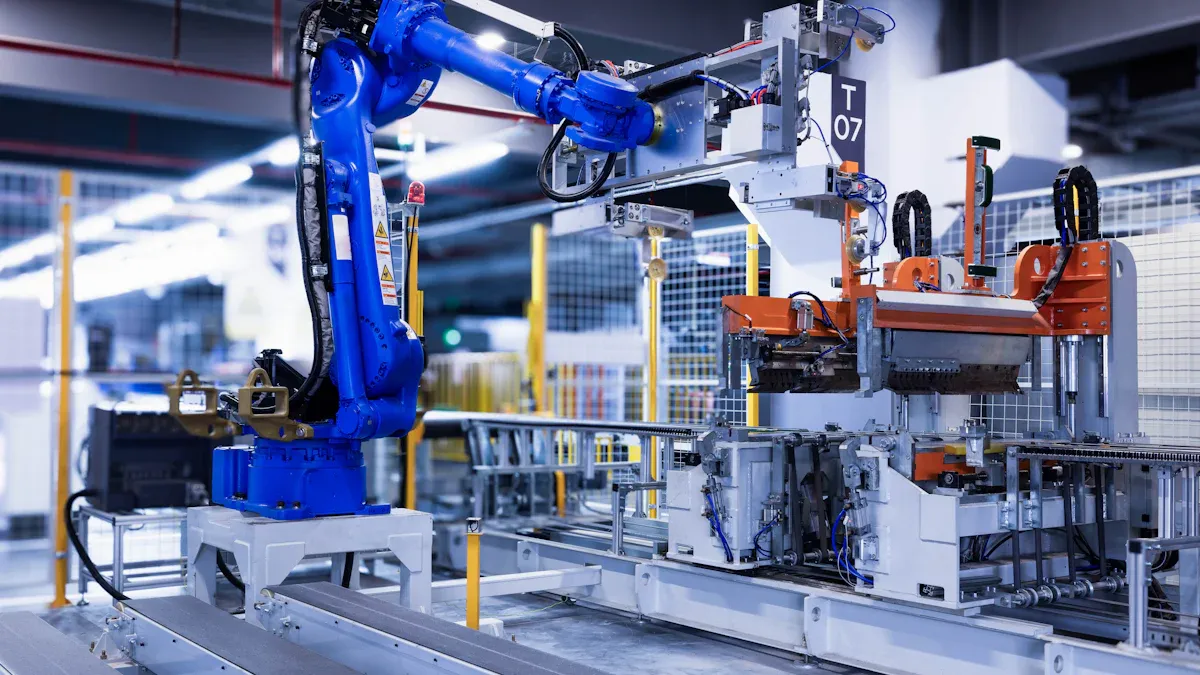

- These valves help robots move precisely. They also make assembly lines faster. This means factories can make more products quickly.

- Solenoid valves keep products safe and clean. They are used in food, medicine, and chemical factories. This helps prevent contamination and ensures good quality.

- Solenoid valves help clean machines automatically. They also manage water treatment. This makes sure water is clean and safe to use.

- Solenoid valves work with computers. This allows people to control them from far away. This makes industrial processes more efficient and reliable.

The Foundational Role of Pneumatic Solenoid Valves in Industry

What Are Industrial Solenoid Valves

Industrial solenoid valves are essential devices that control the flow of liquids or gases in automated systems. They operate electromechanically, meaning an electric current activates them. These valves are crucial for precision in many industrial applications. A typical pneumatic solenoid valve consists of several key components working together:

- Coil: This part acts like an electromagnet. It changes electrical energy into a magnetic force. Its voltage and power consumption are important when choosing the right valve, and its design affects how quickly and efficiently the valve responds.

- Plunger: This is the moving piece inside the valve. It regulates the flow of fluid. Its design, material, and exact movement are vital for accurate fluid control and the valve’s overall effectiveness.

- Body: This provides the valve’s structure and holds all the internal parts. Its construction and material determine if it can handle different fluids and environments, which impacts the valve’s durability and reliability.

How Solenoid Valves Control Pneumatic Systems

Solenoid valves manage pneumatic systems by converting electrical signals into mechanical actions. When electricity flows through the coil, it creates a magnetic field. This field pulls the plunger, which then opens or closes the valve’s orifice. This action controls the air or gas flow. Programmable Logic Controllers (PLCs) often integrate with these valves in pneumatic systems. PLCs manage the valves by sending electric pulses. This allows for remote operation and coordinates various devices within complex automated machinery. This integration significantly boosts efficiency and reduces the need for manual labor in industrial automation.

Core Advantages of Solenoid Valves in Automation

Solenoid valves offer significant advantages in industrial automation. They provide rapid response times, allowing for quick adjustments in fluid or gas flow. Their precise control ensures exact amounts of materials are dispensed or directed, which is critical for quality and consistency. These valves are also highly reliable, performing consistently over long periods with minimal maintenance. Their ability to integrate seamlessly into automated systems makes them indispensable for modern industrial processes, enhancing productivity and operational safety.

Optimizing Manufacturing and Assembly Lines with Solenoid Valves

Precision Control in Robotic Systems

Robotic systems rely heavily on precise control for their complex movements and tasks. Solenoid Valves are crucial here. They provide the exact pneumatic control robots need. This allows for very accurate actions. For example, in automated welding, these valves control shielding gas flow. They open 0.2 seconds before the torch activates. They close 0.1 seconds after welding finishes. This ensures weld quality and prevents gas waste. Their rapid response, often within 10-100 milliseconds, significantly shortens production cycles. This boosts output. Consider beverage filling lines; multiple operations per second become achievable.

Solenoid Valves also support high-frequency cycles. They can withstand hundreds or thousands of starts and stops per minute. This happens without mechanical fatigue. This capability allows for complex motion profiles. For instance, SMT placement machines use them. They control vacuum for picking and placing tiny electronic components many times per second. This directly impacts placement efficiency and accuracy. Their compact design also makes integration and maintenance easier. This minimizes downtime during any faults.

Accelerating Automated Assembly Processes

Automated assembly lines demand speed and accuracy. Solenoid Valves help achieve both. They quickly actuate grippers, clamps, and other tools. This speeds up the assembly of products. They ensure each component is placed correctly and efficiently. This reduces manual intervention. It also increases the overall throughput of the line.

Minimizing Production Downtime

Downtime costs manufacturers a lot of money. Solenoid Valves contribute to minimizing this. Their reliability means fewer breakdowns. Their quick response helps diagnose and fix issues faster. They also allow for modular system designs. This makes parts easier to replace. All these factors keep production lines running smoothly. They reduce interruptions and maintain high productivity levels.

Revolutionizing Process Control in Chemical and Pharmaceutical Industries with Solenoid Valves

Precise Fluid Flow Regulation

Chemical and pharmaceutical industries demand extreme precision. Solenoid valves offer exact control over fluid flow. They manage the precise amounts of liquids or gases. This ensures accurate mixing of ingredients. It also helps maintain specific reaction conditions. This level of control directly impacts product quality and consistency. It also optimizes process efficiency.

Enhancing Safety in Hazardous Environments

Safety is paramount in these industries, especially with hazardous materials. Solenoid valves play a critical role in enhancing safety. They act as reliable shut-off devices. This prevents dangerous leaks or spills. They also control the flow of inert gases for purging. This reduces explosion risks. Manufacturers ensure these valves meet strict safety standards. For example, UL Certification shows compliance for North America. CE Marking and ATEX Certification are vital for explosive environments in the European Union. CSA Certification is important for Canada. IECEx Certification is an international standard for explosive atmospheres. NEMA Ratings and IP Ratings specify protection against dust and liquids. These certifications confirm the valves can operate safely in challenging conditions.

Maintaining Product Purity and Sterility

Product purity and sterility are non-negotiable in pharmaceuticals. Solenoid Valves are essential for maintaining these high standards. They act as quick shut-off devices. This prevents contamination if production conditions change. They also control the flow of cleaning agents during Cleaning-In-Place (CIP) processes. This ensures thorough and consistent cleaning. This keeps the production environment free from contaminants. Furthermore, these valves integrate into leak detection systems. These systems prevent leaks and monitor air quality in cleanrooms. This ensures a sterile and safe production process.

Boosting Efficiency in Food and Beverage Processing with Solenoid Valves

Hygienic Control of Ingredients and Processes

Food and beverage processing demands strict hygiene. Manufacturers must prevent contamination. They use specialized equipment to meet these high standards. Valves in these systems must resist contaminants. They also need to handle various processing environments. These include meat and abattoir industries, fish canneries, and ready meal production. They also work in fruit and vegetable canneries. Stainless steel is a common material for these valves. This material is chosen for its contaminant-resistant qualities. It also works well in salmon packing lines, fish fillet preparation, and pasteurization systems. These systems often require high-pressure capabilities.

Automated Cleaning-in-Place (CIP) Systems

Automated Cleaning-in-Place (CIP) systems are vital for hygiene. They clean equipment without disassembly. These systems rely on precise control. Valves manage the flow of cleaning solutions and rinses. They ensure each part of the system gets thoroughly cleaned. This automation saves time and labor. It also guarantees consistent cleaning results. This helps maintain a sterile production environment.

Ensuring Consistent Product Quality

Maintaining consistent product quality is crucial in food and beverage production. Valves are essential in beverage bottling and filling lines. They use sanitary-grade materials and FDA-approved seals. This ensures operations remain contamination-free. Often, normally closed valves control liquid flow precisely when needed.

- These valves regulate the movement of process fluids.

- They ensure consistency in flow and timing.

- This consistency directly improves product quality.

- It also reduces waste in continuous production.

This precise control helps deliver the same great taste and quality every time.

Enhancing Performance in Water Treatment and Utilities with Solenoid Valves

Automated Valve Actuation for Flow Management

Water treatment plants rely on precise flow control. Automated valve actuation, often driven by these valves, offers increased precision and reliability. This allows real-time adjustments based on treatment needs. It minimizes over or under-treatment of water due to quick and accurate flow changes. This is crucial for maintaining balance in treatment processes and ensuring water quality standards. These systems also regulate pressure to protect piping and equipment, ensuring optimal treatment conditions. They prevent pressure surges that could lead to system failures or safety breaches. This enhances efficiency in wastewater treatment stages by facilitating segregation and controlled treatment of various streams. It optimizes processes in areas like sedimentation tanks, filtration units, and chemical dosing stations. This reduces manual intervention and assures compliance with environmental standards for treated water.

Optimizing Filtration and Purification Processes

In municipal water systems, these valves are vital for optimizing filtration and purification. Pilot-operated valves effectively handle high-pressure flows. They regulate water levels in tanks and maintain appropriate pressure. They also automate processes in both municipal and industrial water treatment facilities. These valves manage chemical flow in water treatment plants. They control municipal water supplies and regulate wastewater treatment processes. Their direct electrical control simplifies integration into control systems. This allows for sophisticated programming. Their fast actuation time permits rapid opening and closing of fluid pathways. This is crucial for scenarios needing quick flow control changes.

Facilitating Remote Monitoring and Control

Modern utility infrastructure benefits greatly from remote monitoring and control. A dual output wireless (IOT) controller provides web-based control for these valves. It operates independently for compressed air, inert gas, or liquid systems. LoRaWAN® or GSM/LTE telemetry integrates into the controller. This allows customers to connect to existing public LPWAN infrastructure. They can also operate completely remotely via the GSM network. MAC Valve latching technology, an ultra-low power solution, enables industrial and commercial use on air and inert gas systems. The controller can operate a single valve over 250,000 times with a battery life exceeding 10 years, including telemetry. A solar-powered version offers even greater independence. This system does not rely on client WIFI, local electricity, or existing hardwired SCADA control systems, ensuring independent operation.

Solenoid Valves are truly essential for modern industrial success. They drive precision, speed, and efficiency across many operations. Their critical role ensures operational reliability and enhances safety in diverse sectors. From manufacturing to water treatment, these valves make processes smoother and more dependable. The continuous evolution of this technology promises even greater advancements. We can expect future innovations to further boost industrial automation.

FAQ

What is a solenoid valve?

A solenoid valve is an electromechanical device. It controls the flow of liquids or gases in automated systems. An electric current activates a coil, creating a magnetic field. This field moves a plunger, which then opens or closes the valve’s pathway.

How do solenoid valves control industrial systems?

Solenoid valves convert electrical signals into mechanical actions. They open or close to manage air or gas flow. Programmable Logic Controllers (PLCs) often send electric pulses to these valves. This allows for precise, remote control and automation in complex machinery.

What are the key advantages of using solenoid valves in automation?

Solenoid valves offer rapid response times for quick flow adjustments. They provide precise control, ensuring exact material amounts. These valves are also highly reliable, performing consistently with minimal maintenance. They integrate easily into automated systems, boosting productivity.

Which industries benefit most from solenoid valves?

Many industries use solenoid valves. Manufacturing, assembly, packaging, material handling, chemical, pharmaceutical, food and beverage, and water treatment all benefit. They rely on these valves for precision, efficiency, and safety in their operations.